SEE NOTE (7)

FOR SPACING

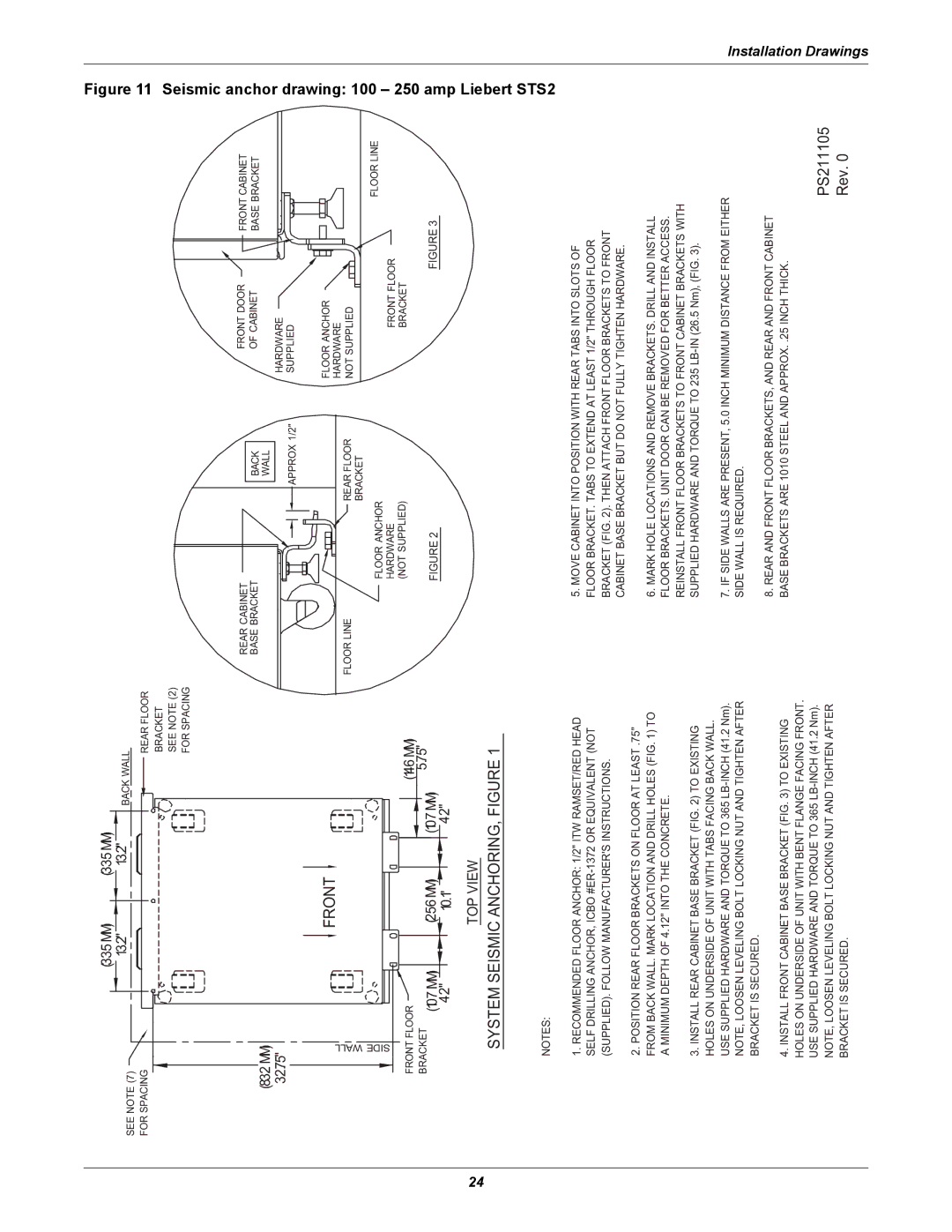

(832 MM) 32.75"

(335 MM) 13.2"

(335 MM)

13.2" |

| BACK WALL | ||||||

|

|

|

|

|

|

|

|

|

![]()

![]() REAR FLOOR

REAR FLOOR

BRACKET

SEE NOTE (2)

FOR SPACING

REAR CABINET

BASE BRACKETBACK

WALL

APPROX 1/2"

FRONT DOOR | FRONT CABINET |

OF CABINET | BASE BRACKET |

HARDWARE |

|

SUPPLIED |

|

Figure 11 Seismic anchor

24

WALL | FRONT |

| BRACKET |

| FLOOR LINE | ||

|

| REAR FLOOR | |

SIDE |

|

| FLOOR ANCHOR |

|

|

| HARDWARE |

FRONT FLOOR |

| (146 MM) | (NOT SUPPLIED) |

|

| ||

BRACKET | (256 MM) | 5.75" | FIGURE 2 |

(107 MM) | (107 MM) | ||

4.2" | 10.1" | 4.2" |

|

TOP VIEW

SYSTEM SEISMIC ANCHORING, FIGURE 1

FLOOR ANCHOR |

HARDWARE |

NOT SUPPLIED |

FLOOR LINE |

FRONT FLOOR |

BRACKET |

FIGURE 3

drawing: 100 – 250 amp Liebert STS2

NOTES:

1.RECOMMENDED FLOOR ANCHOR: 1/2" ITW RAMSET/RED HEAD SELF DRILLING ANCHOR, ICBO

2.POSITION REAR FLOOR BRACKETS ON FLOOR AT LEAST .75" FROM BACK WALL. MARK LOCATION AND DRILL HOLES (FIG. 1) TO A MINIMUM DEPTH OF 4.12" INTO THE CONCRETE.

3.INSTALL REAR CABINET BASE BRACKET (FIG. 2) TO EXISTING HOLES ON UNDERSIDE OF UNIT WITH TABS FACING BACK WALL. USE SUPPLIED HARDWARE AND TORQUE TO 365

NOTE, LOOSEN LEVELING BOLT LOCKING NUT AND TIGHTEN AFTER BRACKET IS SECURED.

4.INSTALL FRONT CABINET BASE BRACKET (FIG. 3) TO EXISTING HOLES ON UNDERSIDE OF UNIT WITH BENT FLANGE FACING FRONT. USE SUPPLIED HARDWARE AND TORQUE TO 365

NOTE, LOOSEN LEVELING BOLT LOCKING NUT AND TIGHTEN AFTER BRACKET IS SECURED.

5.MOVE CABINET INTO POSITION WITH REAR TABS INTO SLOTS OF FLOOR BRACKET. TABS TO EXTEND AT LEAST 1/2" THROUGH FLOOR BRACKET (FIG. 2). THEN ATTACH FRONT FLOOR BRACKETS TO FRONT CABINET BASE BRACKET BUT DO NOT FULLY TIGHTEN HARDWARE.

6.MARK HOLE LOCATIONS AND REMOVE BRACKETS. DRILL AND INSTALL FLOOR BRACKETS. UNIT DOOR CAN BE REMOVED FOR BETTER ACCESS. REINSTALL FRONT FLOOR BRACKETS TO FRONT CABINET BRACKETS WITH SUPPLIED HARDWARE AND TORQUE TO 235

7.IF SIDE WALLS ARE PRESENT, 5.0 INCH MINIMUM DISTANCE FROM EITHER SIDE WALL IS REQUIRED.

8.REAR AND FRONT FLOOR BRACKETS, AND REAR AND FRONT CABINET BASE BRACKETS ARE 1010 STEEL AND APPROX. .25 INCH THICK.

PS211105

Rev. 0

Installation Drawings