RUSKA 7350

Users Manual

76xx Interface Board

This board interfaces and conditions the pump position signal. The board interfaces these signals between the electronic and pneumatic module. This board also provides a 0 – 10 VDC signal to 0 – 100 psi electronic pneumatic regulators and the motor controller.

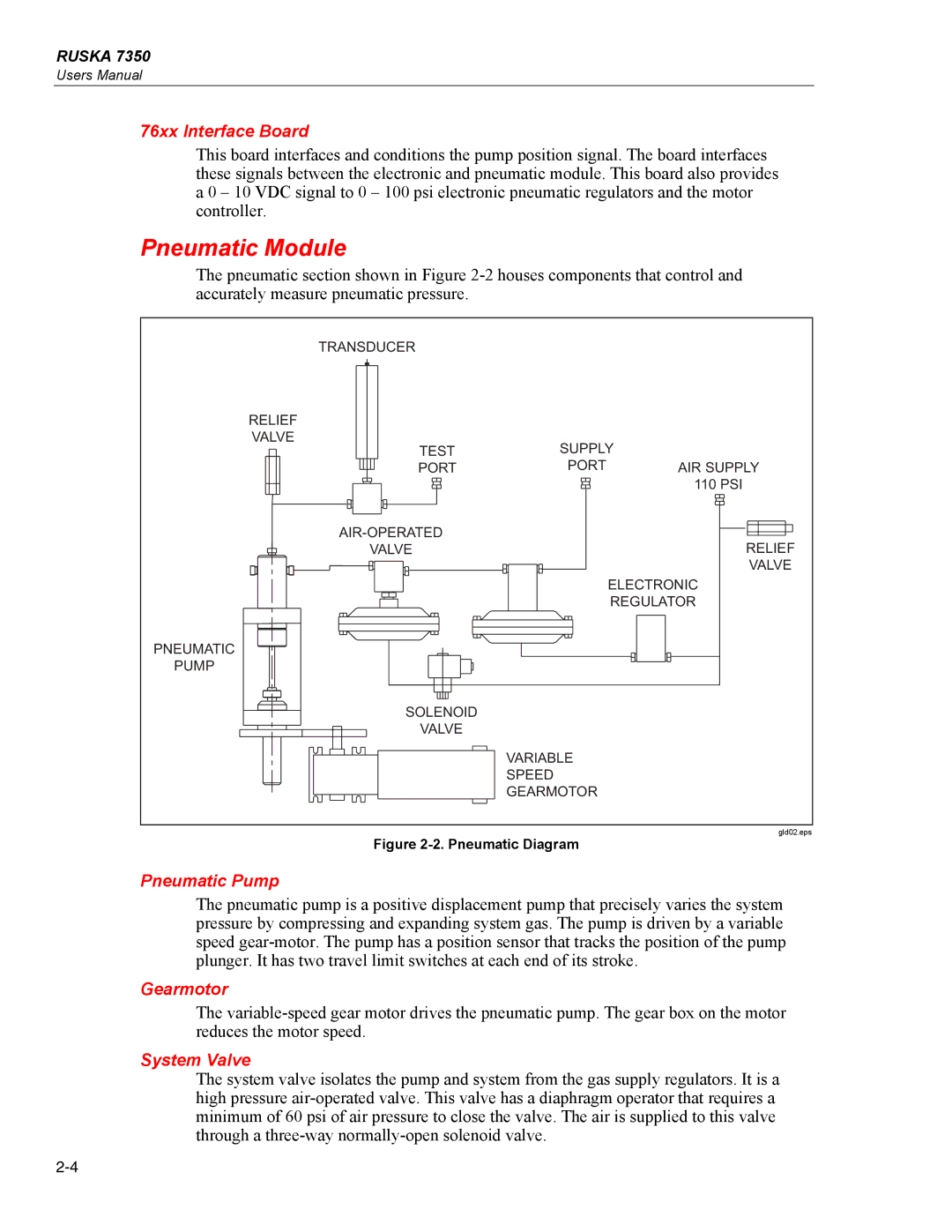

Pneumatic Module

The pneumatic section shown in Figure

TRANSDUCER |

|

|

RELIEF |

|

|

VALVE | SUPPLY | |

TEST | ||

PORT | PORT | AIR SUPPLY |

|

| 110 PSI |

| RELIEF | |

VALVE |

| |

|

| VALVE |

|

| ELECTRONIC |

|

| REGULATOR |

PNEUMATIC |

|

|

PUMP |

|

|

SOLENOID |

|

|

VALVE |

|

|

| VARIABLE |

|

| SPEED |

|

| GEARMOTOR |

|

|

| gld02.eps |

Figure 2-2. Pneumatic Diagram

Pneumatic Pump

The pneumatic pump is a positive displacement pump that precisely varies the system pressure by compressing and expanding system gas. The pump is driven by a variable speed

Gearmotor

The

System Valve

The system valve isolates the pump and system from the gas supply regulators. It is a high pressure