Application – All Motors

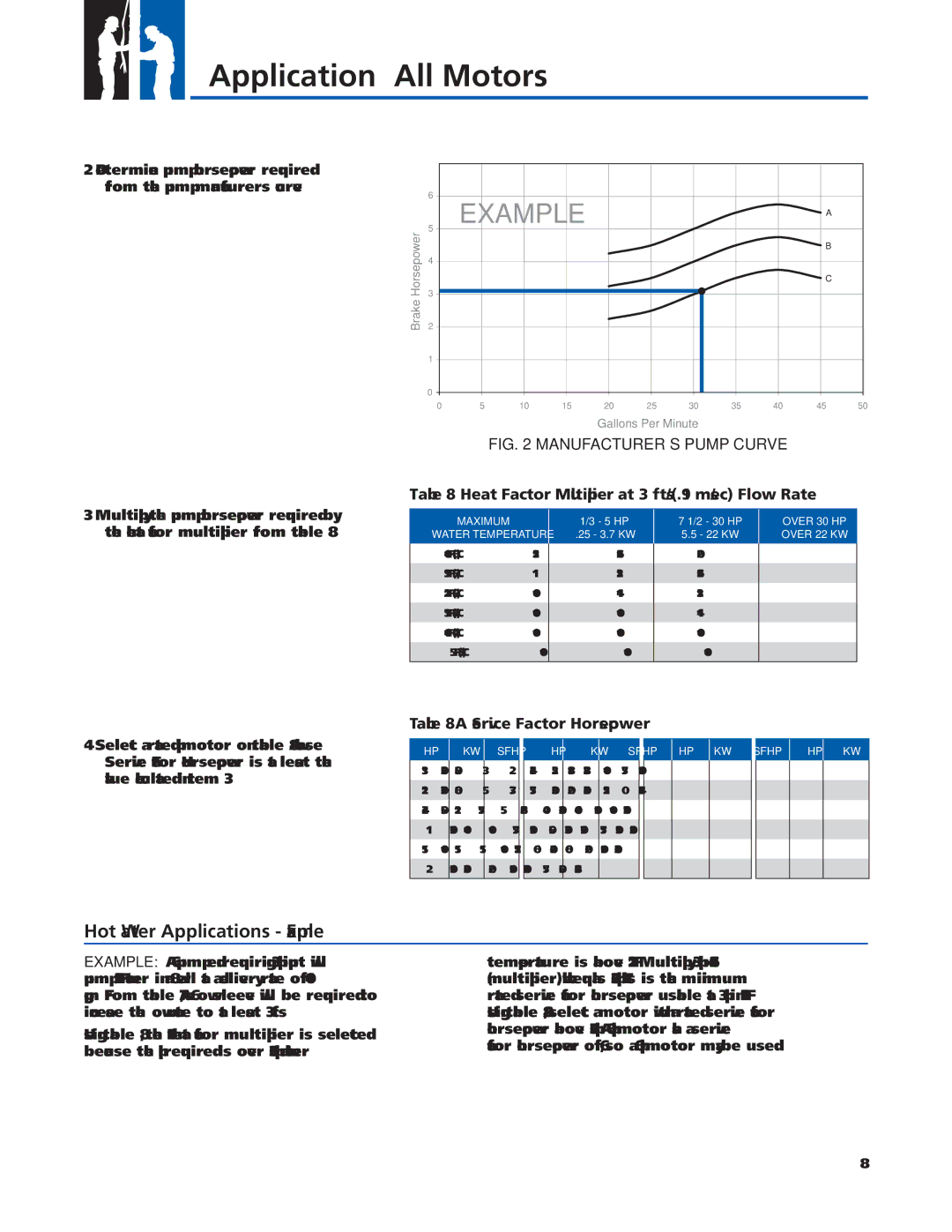

2.Determine pump horsepower required from the pump manufacturer’s curve.

| 6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| EXAMPLE |

|

|

|

|

| A |

|

| |||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Horsepower | 5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| B |

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

Brake | 3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| 0 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |||

Gallons Per Minute

FIG. 2 MANUFACTURER’S PUMP CURVE

Table 8 Heat Factor Multiplier at 3 ft/s (.91 m/sec) Flow Rate

3.Multiply the pump horsepower required by the heat factor multiplier from table 8.

MAXIMUM

WATER TEMPERATURE

140 °F (60 °C)

131 °F (55 °C)

122 °F (50 °C)

113 °F (45 °C)

104 °F (40 °C)

95 °F (35 °C)

1/3 - 5 HP

.25 - 3.7 KW

1.25

1.11

1.00

1.00

1.00

1.00

7 1/2 - 30 HP

5.5- 22 KW

1.62

1.32

1.14

1.00

1.00

1.00

OVER 30 HP OVER 22 KW

2.00

1.62

1.32

1.14

1.00

1.00

Table 8A Service Factor Horsepower

4.Select a rated hp motor on table 8A whose Service Factor Horsepower is at least the value calculated in Item 3.

HP

1/3

1/2

3/4

1

1.5

2

KW SFHP

0.250.58

0.370.80

0.551.12

0.751.40

1.101.95

1.502.50

HP | KW | SFHP |

| HP | KW | SFHP |

| HP | KW | SFHP |

3 | 2.2 | 3.45 |

| 25 | 18.5 | 28.75 |

| 100 | 75 | 115.00 |

5 | 3.7 | 5.75 |

| 30 | 22.0 | 34.50 |

| 125 | 90 | 143.75 |

7.5 | 5.5 | 8.62 |

| 40 | 30.0 | 46.00 |

| 150 | 110 | 172.50 |

10 | 7.5 | 11.50 |

| 50 | 37.0 | 57.50 |

| 175 | 130 | 201.25 |

15 | 11.0 | 17.25 |

| 60 | 45.0 | 69.00 |

| 200 | 150 | 230.00 |

20 | 15.0 | 23.00 |

| 75 | 55.0 | 86.25 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hot Water Applications - Example

EXAMPLE: A 6" pump end requiring 39 hp input will pump 124 °F water in an 8" well at a delivery rate of 140 gpm. From table 7A, a 6" fl ow sleeve will be required to increase the fl ow rate to at least 3 ft/s

Using table 8, the 1.62 heat factor multiplier is selected because the hp required is over 30 hp and water

temperature is above 122 °F. Multiply 39 hp x 1.62 (multiplier), which equals 63.2 hp. This is the minimum rated service factor horsepower usable at 39 hp in 124 °F. Using table 8A, select a motor with a rated service factor horsepower above 63.2 hp. A 60 hp motor has a service factor horsepower of 69, so a 60 hp motor may be used.

8