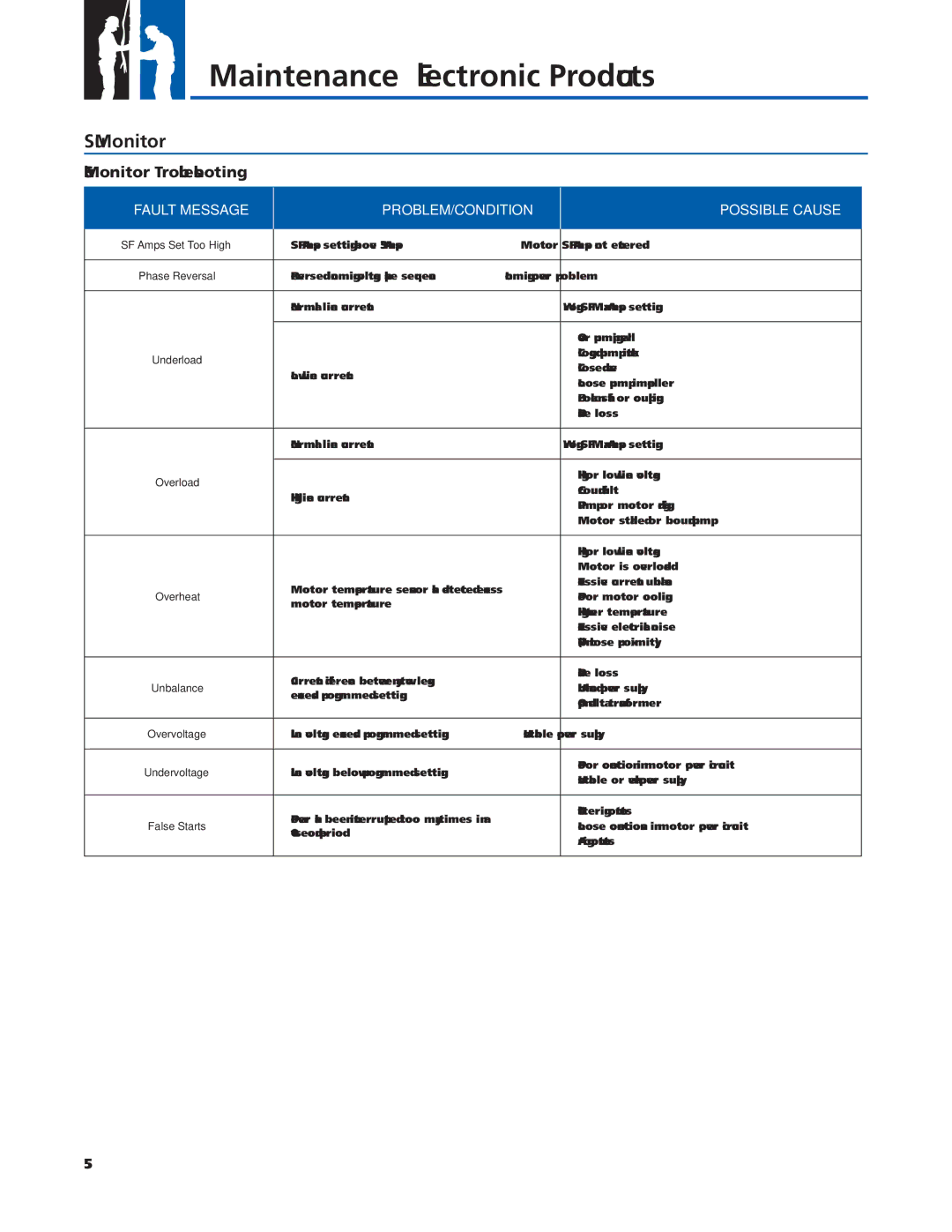

Maintenance – Electronic Products

SubMonitor

SubMonitor Troubleshooting

FAULT MESSAGE

PROBLEM/CONDITION

POSSIBLE CAUSE

SF Amps Set Too High | SF Amps setting above 359 Amps. | Motor SF Amps not entered. | |

|

|

| |

Phase Reversal | Reversed incoming voltage phase sequence. | Incoming power problem. | |

|

|

| |

| Normal line current. | Wrong SF Max Amps setting. | |

|

|

| |

|

| Over pumping well. | |

Underload |

| Clogged pump intake. | |

| Closed valve. | ||

| Low line current. | ||

| Loose pump impeller. | ||

|

| ||

|

| Broken shaft or coupling. | |

|

| Phase loss. | |

|

|

| |

| Normal line current. | Wrong SF Max Amps setting. | |

|

|

| |

Overload |

| High or low line voltage. | |

| Ground fault. | ||

| High line current. | ||

| Pump or motor dragging. | ||

|

| ||

|

| Motor stalled or bound pump. | |

|

|

| |

|

| High or low line voltage. | |

|

| Motor is overloaded. | |

| Motor temperature sensor has detected excess | Excessive current unbalance. | |

Overheat | Poor motor cooling. | ||

motor temperature. | |||

| High water temperature. | ||

|

| ||

|

| Excessive electrical noise | |

|

| (VFD in close proximity). | |

|

|

| |

| Current difference between any two legs | Phase loss. | |

Unbalance | Unbalanced power supply. | ||

exceeds programmed setting. | |||

| Open delta transformer. | ||

|

| ||

|

|

| |

Overvoltage | Line voltage exceeds programmed setting. | Unstable power supply. | |

|

|

| |

Undervoltage | Line voltage below programmed setting. | Poor connection in motor power circuit. | |

Unstable or weak power supply. | |||

|

| ||

|

|

| |

| Power has been interrupted too many times in a | Chattering contacts. | |

False Starts | Loose connections in motor power circuit. | ||

10 second period. | |||

| Arcing contacts. | ||

|

| ||

|

|

|

59