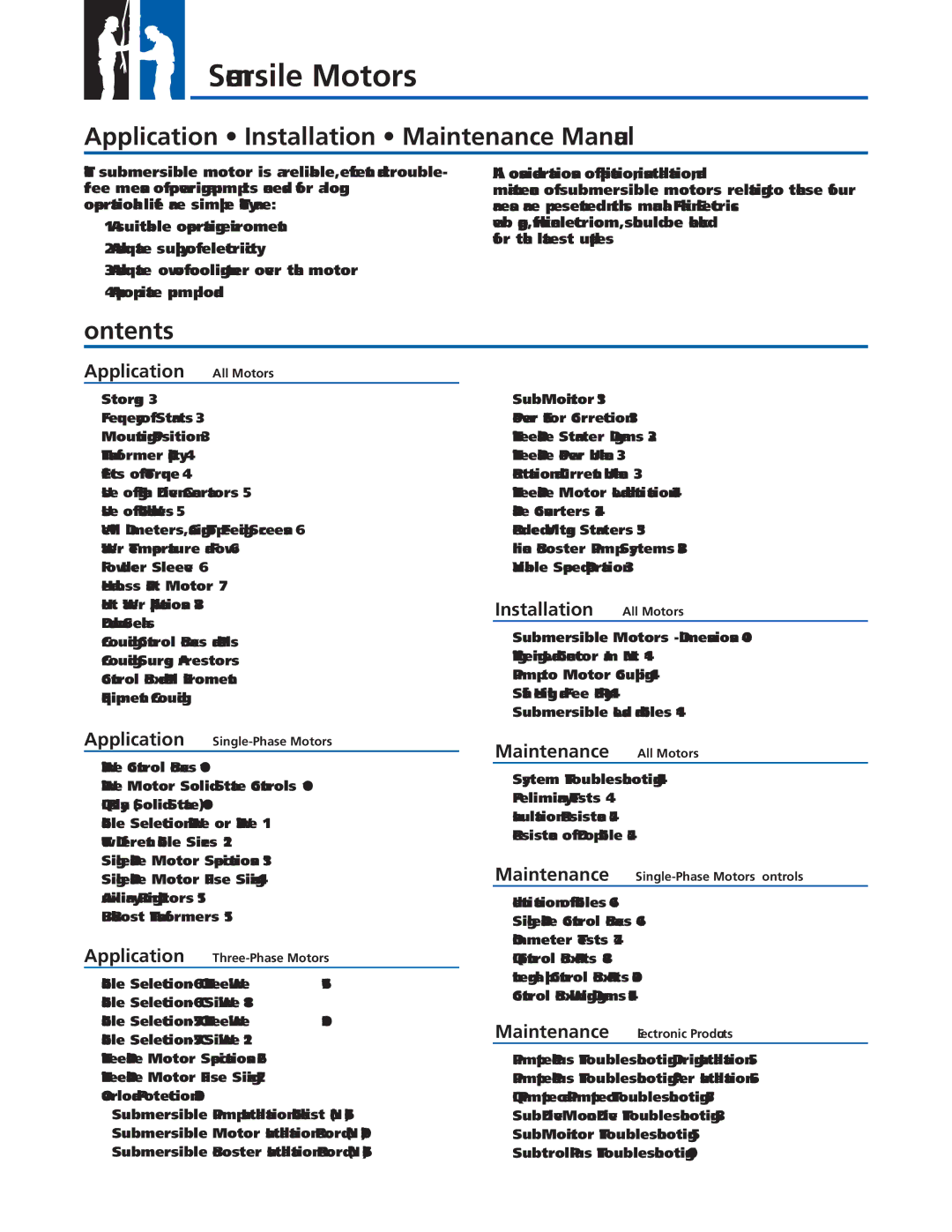

Submersible Motors

Application • Installation • Maintenance Manual

The submersible motor is a reliable, effi cient and trouble- free means of powering a pump. Its needs for a long operational life are simple. They are:

1.A suitable operating environment

2.An adequate supply of electricity

3.An adequate fl ow of cooling water over the motor

4.An appropriate pump load

All considerations of application, installation, and maintenance of submersible motors relating to these four areas are presented in this manual. Franklin Electric’s web page,

Contents

Application – All Motors |

|

Storage | 3 |

Frequency of Starts | 3 |

Mounting Position | 3 |

Transformer Capacity | 4 |

Effects of Torque | 4 |

Use of Engine Driven Generators | 5 |

Use of Check Valves | 5 |

Well Diameters, Casing, Top Feeding, Screens | 6 |

Water Temperature and Flow | 6 |

Flow Inducer Sleeve | 6 |

Head Loss Past Motor | 7 |

Hot Water Applications | |

Drawdown Seals | 9 |

Grounding Control Boxes and Panels | 9 |

Grounding Surge Arrestors | 9 |

Control Box and Panel Environment | 9 |

Equipment Grounding | 9 |

Application – |

|

10 | |

10 | |

QD Relays (Solid State) | 10 |

Cable Selection | 11 |

Two Different Cable Sizes | 12 |

13 | |

14 | |

Auxiliary Running Capacitors | 15 |

15 | |

Application – |

|

Cable Selection - 60 °C | |

Cable Selection - 60 °C | 18 |

Cable Selection - 75 °C | |

Cable Selection - 75 °C | 21 |

27 | |

Overload Protection | |

Submersible Pump Installation Checklist (No. 3656) | |

Submersible Motor Installation Record (No. 2207) |

|

Submersible Booster Installation Record (No. 3655) | |

SubMonitor | 31 |

Power Factor Correction | 31 |

32 | |

33 | |

Rotation and Current Unbalance | 33 |

34 | |

Phase Converters | 34 |

Reduced Voltage Starters | 35 |

Inline Booster Pump Systems | |

Variable Speed Operation | 39 |

Installation – All Motors |

|

Submersible Motors - Dimensions | 40 |

Tightening Lead Connector Jam Nut | 41 |

Pump to Motor Coupling | 41 |

Shaft Height and Free End Play | 41 |

Submersible Leads and Cables | 41 |

Maintenance – All Motors |

|

System Troubleshooting | |

Preliminary Tests | 44 |

Insulation Resistance | 45 |

Resistance of Drop Cable | 45 |

Maintenance – | |

Identifi cation of Cables | 46 |

46 | |

Ohmmeter Tests | 47 |

QD Control Box Parts | 48 |

Integral hp Control Box Parts | |

Control Box Wiring Diagrams | |

Maintenance – Electronic Products |

|

55 | |

56 | |

QD Pumptec and Pumptec Troubleshooting | 57 |

SubDrive/MonoDrive Troubleshooting | 58 |

SubMonitor Troubleshooting | 59 |