Maintenance – Electronic Products

SubDrive75, 150, 300, MonoDrive, & MonoDrive XT

The Franklin Electric SubDrive/MonoDrive Constant Pressure controller is a

WARNING: Serious or fatal electrical shock may result from failure to connect the motor, SubDrive/MonoDrive Controller, metal plumbing and all other metal near the motor or cable to the power supply ground terminal using wire no smaller than motor cable wires. To reduce the risk of electrical shock, disconnect power before working on or around the water system. Capacitors inside the SubDrive/MonoDrive Controller can still hold a lethal voltage even after power has been removed. Allow 10 minutes for dangerous internal voltage to discharge. Do not use motor in swimming areas.

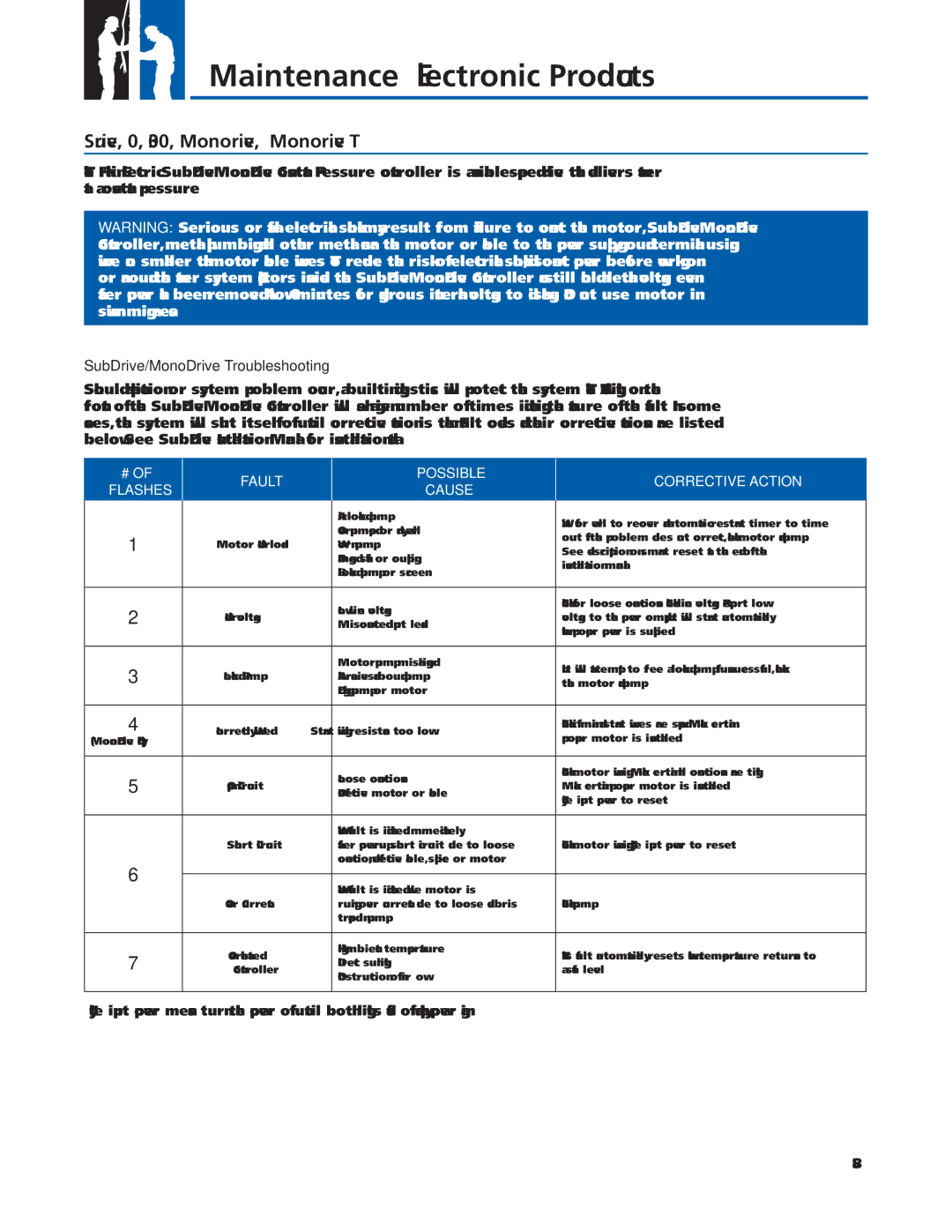

SubDrive/MonoDrive Troubleshooting

Should an application or system problem occur, a

#OF

FLASHES

FAULT

POSSIBLE

CAUSE

CORRECTIVE ACTION

|

| Wait for well to recover and automatic restart timer to time | ||

|

| Overpumped or dry well. | ||

1 |

| out. If the problem does not correct, check motor and pump. | ||

Motor Underload | Worn pump. | |||

See description on “smart reset” at the end of the | ||||

| Damaged shaft or coupling. | |||

|

| installation manual. | ||

|

| Blocked pump or screen. | ||

|

|

| ||

|

|

|

| |

2 |

| Low line voltage. | Check for loose connections. Check line voltage. Report low | |

Undervoltage | voltage to the power company. Unit will start automatically | |||

Misconnected input leads. | ||||

| when proper power is supplied. | |||

|

|

| ||

|

|

|

| |

3 |

| Motor/pump misaligned. | Unit will attempt to free a locked pump. If unsuccessful, check | |

Locked Pump | Abrasive/sand bound pump. | |||

the motor and pump. | ||||

| Dragging pump or motor. | |||

|

|

| ||

|

|

|

| |

4 | Incorrectly Wired | Start winding resistance too low. | Check if main and start wires are swapped. Make certain | |

proper motor is installed. | ||||

(MonoDrive Only) |

|

| ||

|

|

|

| |

5 |

| Loose connections. | Check motor wiring. Make certain all connections are tight. | |

Open Circuit | Make certain proper motor is installed. | |||

Defective motor or cable. | ||||

| *Cycle input power to reset. | |||

|

|

| ||

|

|

|

| |

|

| When fault is indicated immediately |

| |

| Short Circuit | after | Check motor wiring. *Cycle input power to reset. | |

6 |

| connection, defective cable, splice or motor. |

| |

|

|

| ||

| When fault is indicated while motor is |

| ||

|

|

| ||

| Over Current | running, over current due to loose debris | Check pump. | |

|

| trapped in pump. |

| |

|

|

|

| |

7 | Overheated | High ambient temperature. | This fault automatically resets when temperature returns to | |

Direct sunlight. | ||||

Controller | a safe level. | |||

Obstruction of air fl ow. | ||||

|

|

| ||

|

|

|

|

* “Cycle input power” means turn the power off until both lights fade off and apply power again

58