Application – Single-Phase Motors

Two or More Different Cable Sizes Can Be Used

Depending on the installation, any number of combinations of cable may be used.

For example, in a replacement/upgrade installation, the well already has 160 feet of buried #10 cable between the service entrance and the wellhead. A new 3 hp,

From tables 11 & 11A, a 3 hp motor can use up to 300 feet of #10 AWG cable.

The application has 160 feet of #10 AWG copper wire installed.

Using the formula below, 160 feet (actual) ÷ 300 feet (max allowable) is equal to 0.533. This means 53.3% (0.533 x 100) of the allowable voltage drop or loss, which is allowed between the service entrance and the motor,

occurs in this wire. This leaves us 46.7% (1.00 - 0.533

=0.467) of some other wire size to use in the remaining 310 feet “down hole” wire run.

The table shows #8 AWG copper wire is good for 470 feet. Using the formula again, 310 feet (used) ÷ 470 feet (allowed) = 0.660; adding this to the 0.533 determined earlier; 0.533 + 0.660 = 1.193. This combination is greater than 1.00, so the voltage drop will not meet US National Electrical Code recommendations.

Tables 11 & 11A show #6 AWG copper wire is good for 750 feet. Using the formula, 310 ÷ 750 = 0.413, and using these numbers, 0.533 + 0.413 = 0.946, we fi nd this is less than one and will meet the NEC recommended voltage drop.

This works for two, three or more combinations of wire and it does not matter which size wire comes fi rst in the installation.

Actual Length | + | Actual Length | = 1.00 |

Formula: | Max Allowed | ||

Max Allowed |

|

| |

|

|

|

|

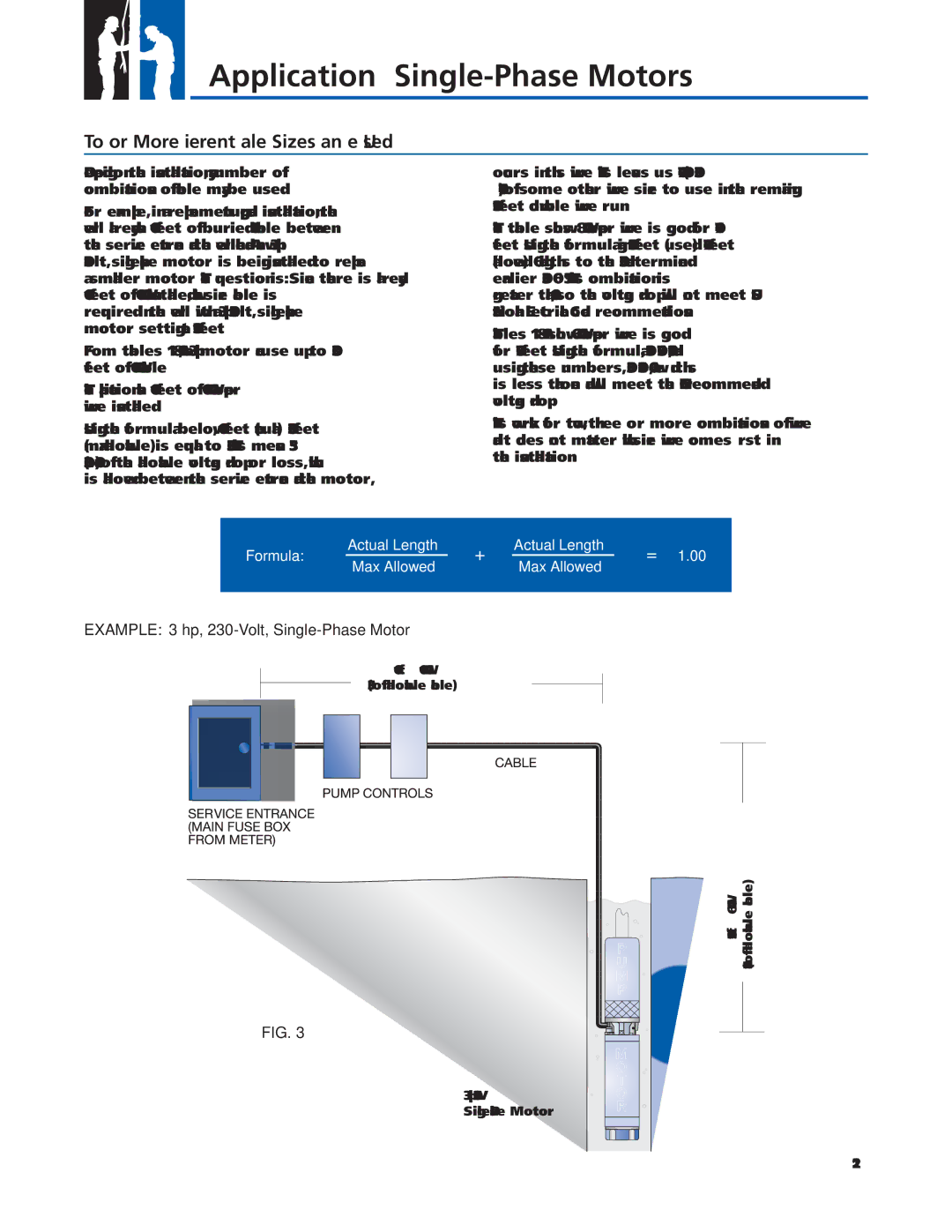

EXAMPLE: 3 hp, 230-Volt, Single-Phase Motor

160 ft #10 AWG

(53.3% of allowable cable)

310 ft #6 AWG (41.3% of allowable cable)

FIG. 3

3 hp, 230 V

12