Maintenance – All Motors

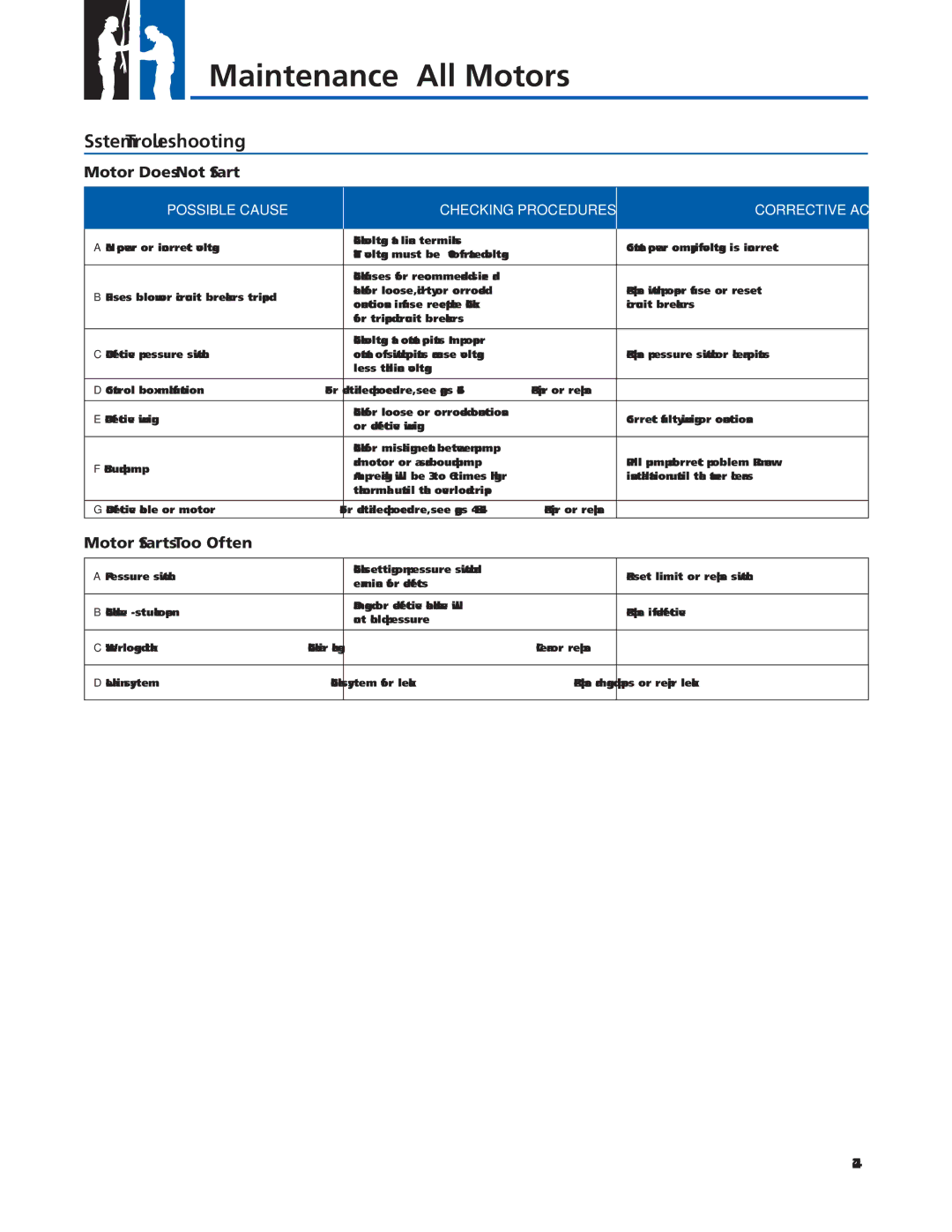

System Troubleshooting

Motor Does Not Start

POSSIBLE CAUSE

CHECKING PROCEDURES

CORRECTIVE ACTION

A. No power or incorrect voltage. | Check voltage at line terminals. | Contact power company if voltage is incorrect. | |

The voltage must be ± 10% of rated voltage. | |||

|

| ||

|

|

| |

| Check fuses for recommended size and |

| |

B. Fuses blown or circuit breakers tripped. | check for loose, dirty or corroded | Replace with proper fuse or reset | |

connections in fuse receptacle. Check | circuit breakers. | ||

| |||

| for tripped circuit breakers. |

| |

|

|

| |

| Check voltage at contact points. Improper |

| |

C. Defective pressure switch. | contact of switch points can cause voltage | Replace pressure switch or clean points. | |

| less than line voltage. |

| |

|

|

| |

D. Control box malfunction. | For detailed procedure, see pages | Repair or replace. | |

|

|

| |

E. Defective wiring. | Check for loose or corroded connections | Correct faulty wiring or connections. | |

or defective wiring | |||

|

| ||

|

|

| |

| Check for misalignment between pump |

| |

F. Bound pump. | and motor or a sand bound pump. | Pull pump and correct problem. Run new | |

Amp readings will be 3 to 6 times higher | installation until the water clears | ||

| |||

| than normal until the overload trips |

| |

|

|

| |

G. Defective cable or motor. | For detailed procedure, see pages 44 & 45. | Repair or replace. | |

|

|

|

Motor Starts Too Often

A. Pressure switch. | Check setting on pressure switch and | Reset limit or replace switch. | |

examine for defects. | |||

|

| ||

|

|

| |

B. Check valve - stuck open. | Damaged or defective check valve will | Replace if defective. | |

not hold pressure. | |||

|

| ||

|

|

| |

C. Waterlogged tank. | Check air charge | Clean or replace. | |

|

|

| |

D. Leak in system. | Check system for leaks. | Replace damaged pipes or repair leaks. | |

|

|

|

42