Installation – All Motors

Tightening Motor Lead Connector Jam Nut

4" Motors:

15 to 20

6" Motors:

50 to 60

8" Motors with

8" Motors with 4 Screw Clamp Plate:

Apply increasing torque to the screws equally in a

Jam nut tightening torques recommended for fi eld assembly are shown. Rubber compression set within the

first few hours after assembly may reduce the jam nut torque. This is a normal condition which does not indicate reduced seal effectiveness. Retightening is not required, but is permissible and recommended if original torque was questionable.

A motor lead assembly should not be reused. A new lead assembly should be used whenever one is removed from the motor, because rubber set and possible damage from removal may prevent proper resealing of the old lead.

All motors returned for warranty consideration must have the lead returned with the motor.

Pump to Motor Coupling

Assemble coupling with

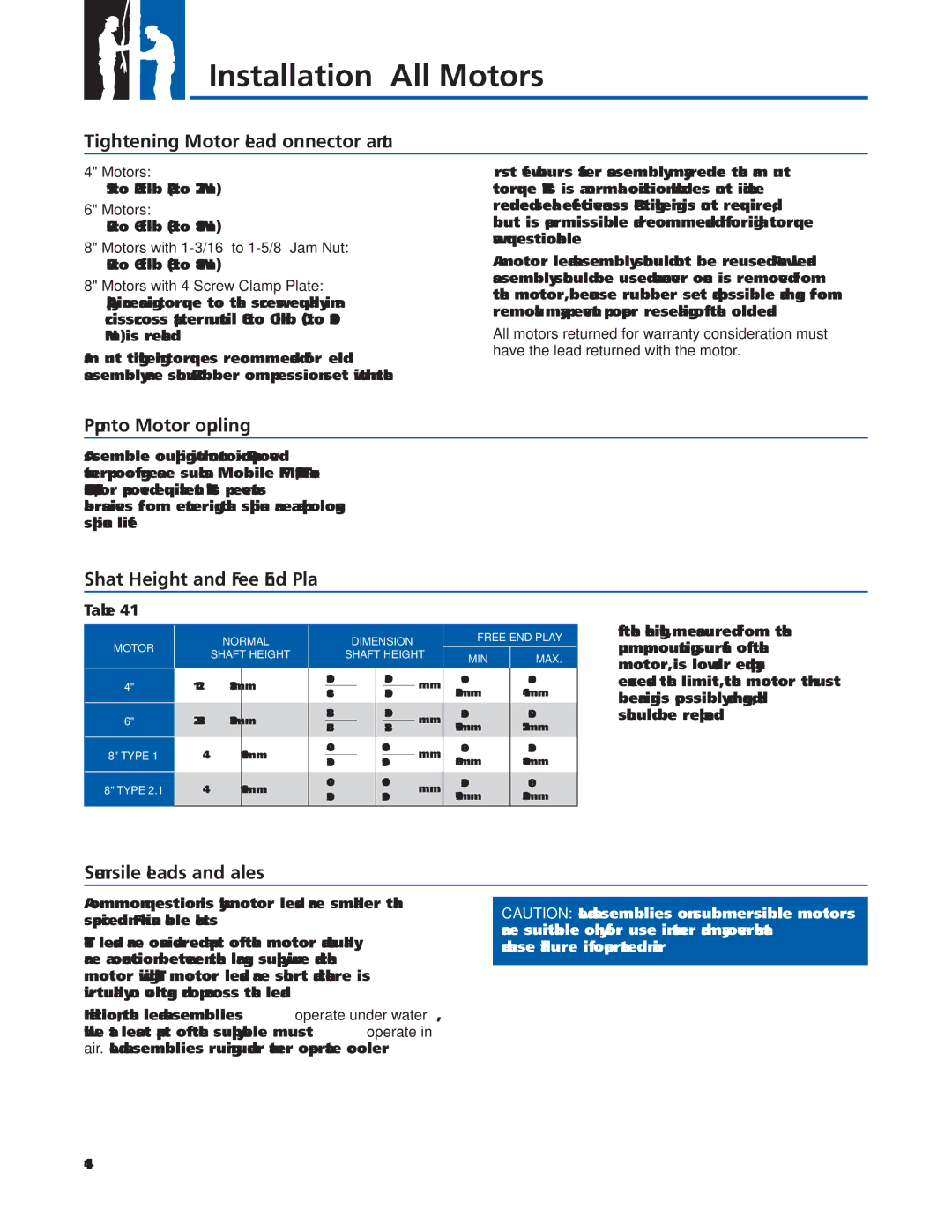

Shaft Height and Free End Play

Table 41

MOTOR

4"

6"

8" TYPE 1

8" TYPE 2.1

NORMAL

SHAFT HEIGHT

1 | 1/2" | 38.1 mm |

2 | 7/8" | 73.0 mm |

| 4" | 101.6 mm |

| 4" | 101.6 mm |

|

|

|

DIMENSION

SHAFT HEIGHT

1.508" |

| 38.30 |

| mm | ||

1.498" |

| 38.05 |

| |||

|

|

| ||||

2.875" |

|

| 73.02 |

| mm | |

2.869" |

| 72.88 |

| |||

|

|

| ||||

4.000" |

| 101.60 mm | ||||

3.990" |

| 101.35 |

| |||

4.000" |

| 101.60 mm | ||||

3.990" | ||||||

| 101.35 |

| ||||

FREE END PLAY

MIN | MAX. |

0.010" |

|

0.045" | |

0.25 mm | 1.14 mm |

0.030" | 0.050" |

0.76 mm | 1.27 mm |

0.008" | 0.032" |

0.20 mm | 0.81 mm |

0.030" | 0.080" |

0.76 mm | 2.03 mm |

|

|

If the height, measured from the

Submersible Leads and Cables

A common question is why motor leads are smaller than specifi ed in Franklin’s cable charts.

The leads are considered a part of the motor and actually are a connection between the large supply wire and the motor winding. The motor leads are short and there is virtually no voltage drop across the lead.

In addition, the lead assemblies operate under water, while at least part of the supply cable must operate in air. Lead assemblies running under water operate cooler.

CAUTION: Lead assemblies on submersible motors are suitable only for use in water and may overheat and cause failure if operated in air.

41