Application – All Motors

a zero head condition. This causes an uplifting or upthrust on the

C.Water Hammer - If the lowest check valve is more than 30 feet above the standing (lowest static) water level, or a lower check valve leaks and the check valve above holds, a vacuum is created in

the discharge piping. On the next pump start, water moving at very high velocity fi lls the void and strikes the closed check valve and the stationary water in the pipe above it, causing a hydraulic shock. This shock can split pipes, break joints and damage the pump and/or motor. Water hammer can often be heard or felt. When discovered, the system should be shut down and the pump installer contacted to correct

the problem.

Wells – Large Diameter, Uncased, Top Feeding and Screened Sections

Franklin Electric submersible motors are designed to operate with a cooling fl ow of water over and around the full length of the motor.

If the pump installation does not provide the minimum fl ow shown in table 6, a fl ow inducer sleeve (fl ow sleeve) must be used. The conditions requiring a fl ow sleeve are:

•Well diameter is too large to meet table 6 fl ow requirements.

•Pump is in an open body of water.

•Pump is in a rock well or below the well casing.

•The well is

•Pump is set in or below screens or perforations.

Water Temperature and Flow

Franklin Electric’s standard submersible motors, except

Table 6 Required Cooling Flow

MINIMUM GPM REQUIRED FOR MOTOR COOLING IN WATER UP TO 86 °F (30 °C).

water up to 86 °F (30 °C). A fl ow of 0.25 ft/s for 4" motors rated 3 hp and higher, and 0.5 ft/s for 6 and 8" motors is required for proper cooling. Table 6 shows minimum fl ow rates, in gpm, for various well diameters and motor sizes.

If a standard motor is operated in water over 86 °F

(30 °C), water fl ow past the motor must be increased to maintain safe motor operating temperatures. See HOT WATER APPLICATIONS on page 7.

NOTE: Franklin Electric offers a line of

CASING OR SLEEVE ID INCHES (MM)

4(102)

5(127)

6(152)

7(178)

8(203)

10 (254)

12 (305)

14 (356)

16 (406)

4" MOTOR

0.25FT/S GPM (L/M)

1.2(4.5)

7 (26.5)

13 (49)

20 (76)

30 (114)

50 (189)

80 (303)

110(416)

150(568)

6" MOTOR

0.50FT/S GPM (L/M)

-

-

9(34)

25 (95)

45(170)

90(340)

140(530)

200(760)

280 (1060)

8" MOTOR

0.50FT/S GPM (L/M)

-

-

-

-

10(40)

55 (210)

110(420)

170(645)

245(930)

0.25 ft/s = 7.62 cm/sec 0.50 ft/s = 15.24 cm/sec 1 inch = 2.54 cm

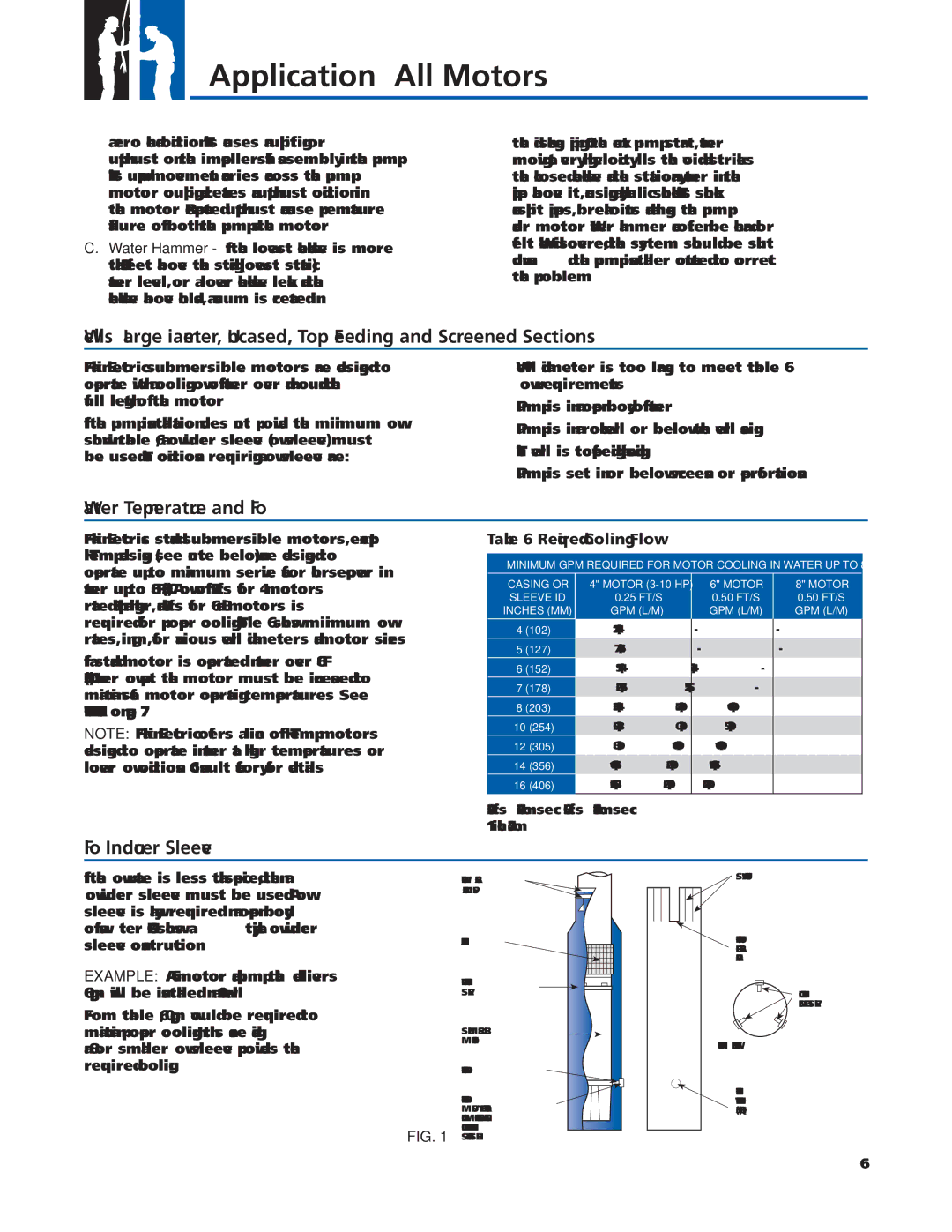

Flow Inducer Sleeve

If the fl ow rate is less than specifi ed, then a

flow inducer sleeve must be used. A fl ow sleeve is always required in an open body of water. FIG. 1 shows a typical fl ow inducer sleeve construction.

EXAMPLE: A 6" motor and pump that delivers 60 gpm will be installed in a 10" well.

From table 6, 90 gpm would be required to maintain proper cooling. In this case adding an 8" or smaller fl ow sleeve provides the required cooling.

WORM GEAR

CLAMPS

| INTAKE |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

| FLOW INDUCER |

|

|

|

|

| |||

|

|

|

|

|

| ||||

| SLEEVE |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

| SUBMERSIBLE |

|

|

|

|

|

|

| |

| MOTOR |

|

|

|

| ||||

| CENTERING BOLT |

|

|

|

| ||||

|

|

|

|

|

|

| |||

| CENTERING BOLTS |

|

|

|

| ||||

| MUST BE LOCATED |

|

|

|

| ||||

| ON MOTOR CASTING. |

|

|

|

| ||||

FIG. 1 | DO NOT LOCATE ON |

|

|

|

| ||||

STATOR SHELL. |

|

|

|

| |||||

SAW CUTS

NOTCH OUT

FOR CABLE

GUARD

LOCK NUTS

INSIDE SLEEVE

BOTTOM END VIEW

CENTERING BOLT HOLE (3 REQUIRED)

6