Setup

Flammable fumes (such as solvent and paint fumes) in work area can ignite or explode.

See Grounding Instructions, page 3.

Do not spray flammable or combustible liquids in a con- fined area.

Keep spray area

Operation

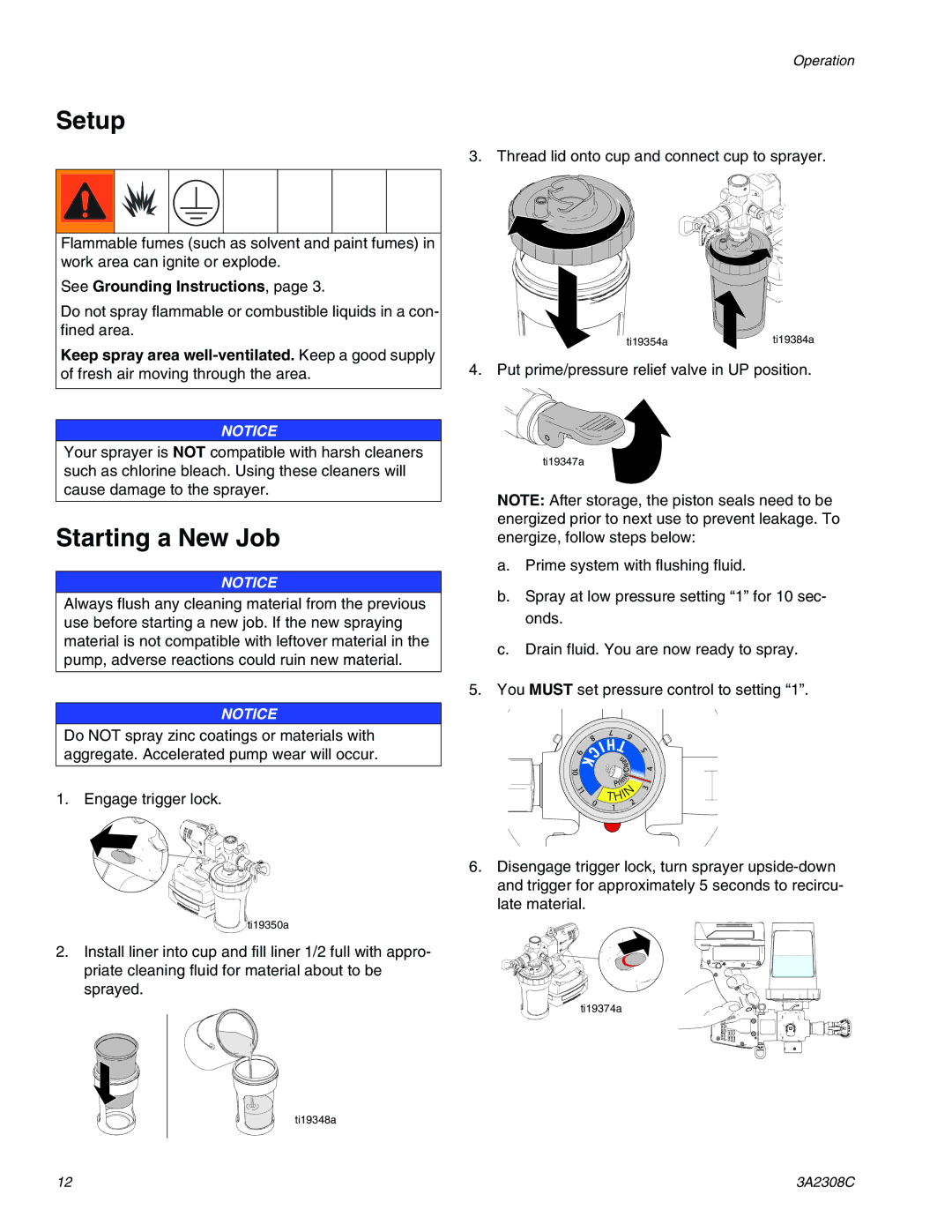

3. Thread lid onto cup and connect cup to sprayer.

ti19354ati19384a

4. Put prime/pressure relief valve in UP position.

NOTICE

Your sprayer is NOT compatible with harsh cleaners such as chlorine bleach. Using these cleaners will cause damage to the sprayer.

Starting a New Job

NOTICE

Always flush any cleaning material from the previous use before starting a new job. If the new spraying material is not compatible with leftover material in the pump, adverse reactions could ruin new material.

NOTICE

Do NOT spray zinc coatings or materials with aggregate. Accelerated pump wear will occur.

1. Engage trigger lock.

![]() ti19350a

ti19350a

2.Install liner into cup and fill liner 1/2 full with appro- priate cleaning fluid for material about to be sprayed.

ti19348a

ti19347a

NOTE: After storage, the piston seals need to be energized prior to next use to prevent leakage. To energize, follow steps below:

a.Prime system with flushing fluid.

b.Spray at low pressure setting “1” for 10 sec- onds.

c.Drain fluid. You are now ready to spray.

5.You MUST set pressure control to setting “1”.

6.Disengage trigger lock, turn sprayer

ti19374a

12 | 3A2308C |