|

| Troubleshooting |

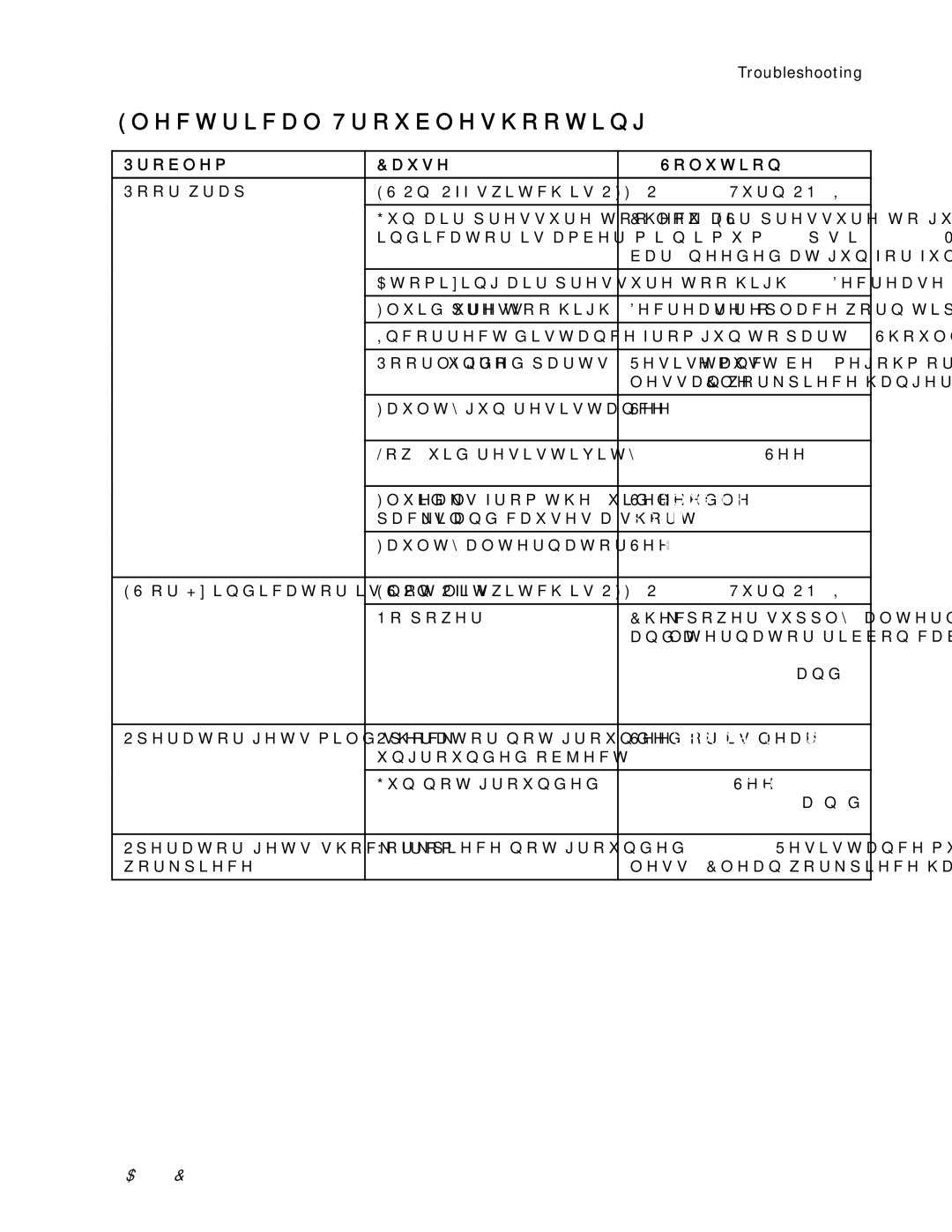

Electrical Troubleshooting |

|

|

|

|

|

Problem | Cause | Solution |

|

|

|

Poor wrap. | ES On/Off switch is OFF (O). | Turn ON (I). |

| Gun air pressure too low (ES | Check air pressure to gun; |

| indicator is amber). | minimum 45 psi (0.32 MPa, 3.2 |

|

| bar) needed at gun for full voltage. |

| Atomizing air pressure too high. | Decrease. |

| Fluid pressure too high. | Decrease, or replace worn tip. |

| Incorrect distance from gun to part. | Should be |

| Poorly grounded parts. | Resistance must be 1 megohm or |

|

| less. Clean workpiece hangers. |

| Faulty gun resistance. | See |

|

| Test Gun Resistance, page 32. |

| Low fluid resistivity. | See |

|

| Check Fluid Resistivity, page 26. |

| Fluid leaks from the fluid needle | See Fluid Needle Replacement, |

| packings and causes a short. | page 44. |

| Faulty alternator. | See Alternator Removal and |

|

| Replacement, page 46. |

ES or Hz indicator is not lit. | ES On/Off switch is OFF (O). | Turn ON (I). |

| No power. | Check power supply, alternator, |

|

| and alternator ribbon cable. See |

|

| Power Supply Removal and |

|

| Replacement, page 45 and |

|

| Alternator Removal and |

|

| Replacement, page 46. |

Operator gets mild shock. | Operator not grounded or is near | See Grounding, page 21. |

| ungrounded object. |

|

| Gun not grounded. | See Check Gun Electrical |

|

| Grounding, page 25, and |

|

| Test Gun Resistance, page 32. |

Operator gets shock from | Workpiece not grounded. | Resistance must be 1 megohm or |

workpiece. |

| less. Clean workpiece hangers. |

3A2495C | 37 |