Consignes DE Sécurité Importantes

313314B

Grounding

Grounding Instructions

Skin Injection Hazard

Fire and Explosion Hazard

Moving Parts Hazard

Equipment Misuse Hazard

Electric Shock Hazard

Pressurized Aluminum Parts Hazard

Mise en garde

Instructions de mise à la terre

Mise a LA Terre

Mise EN Garde

Équipement DE Protection Personnelle

Risques DUS AUX Pièces EN Aluminium Sous Pression

Instrucciones de conexión a tierra

Advertencias

De los vapores explosivos

Peligro DE Incendios Y Explosiones

Lesiones graves y daños materiales

Peligros Debidos a LA Utilización Incorrecta DEL Equipo

English Français Español

Filtre Filtro

Fluid Outlet

Ou de court-circuit Haya un cortocircuito

English

Français

Español

Rallonges

Power Requirements

Extension Cords

Spécification électrique

Pails

Bidones

Tierra. Después dispare la pistola

Pressure Relief

Décompression

Descompresión

Al pulverizador. Apriete firmemente

Setup / Installation / Puesta en marcha

Revise el elemento filtrante de entrada

’huile et l’huile d’entreposage

Turn prime valve down

La gâchette du pistolet

Turn power on

Coloque el tubo de aspiración en la lata de pintura

Ti13023a

Pulvériser

Spray

Clear Clog

Never point gun at your hand or into a rag

Perform Pressure Relief

Position

’écoule

Ouvrir la vanne d’amorçage. Débrancher Le pulvérisateur

15 to 30 seconds to drain fluid

Turn prime valve down Drain position. Unplug sprayer

Secondes pour nettoyer le tuyau de vidange

Ti2895a Ti13029a

Repair / Réparation / Reparación

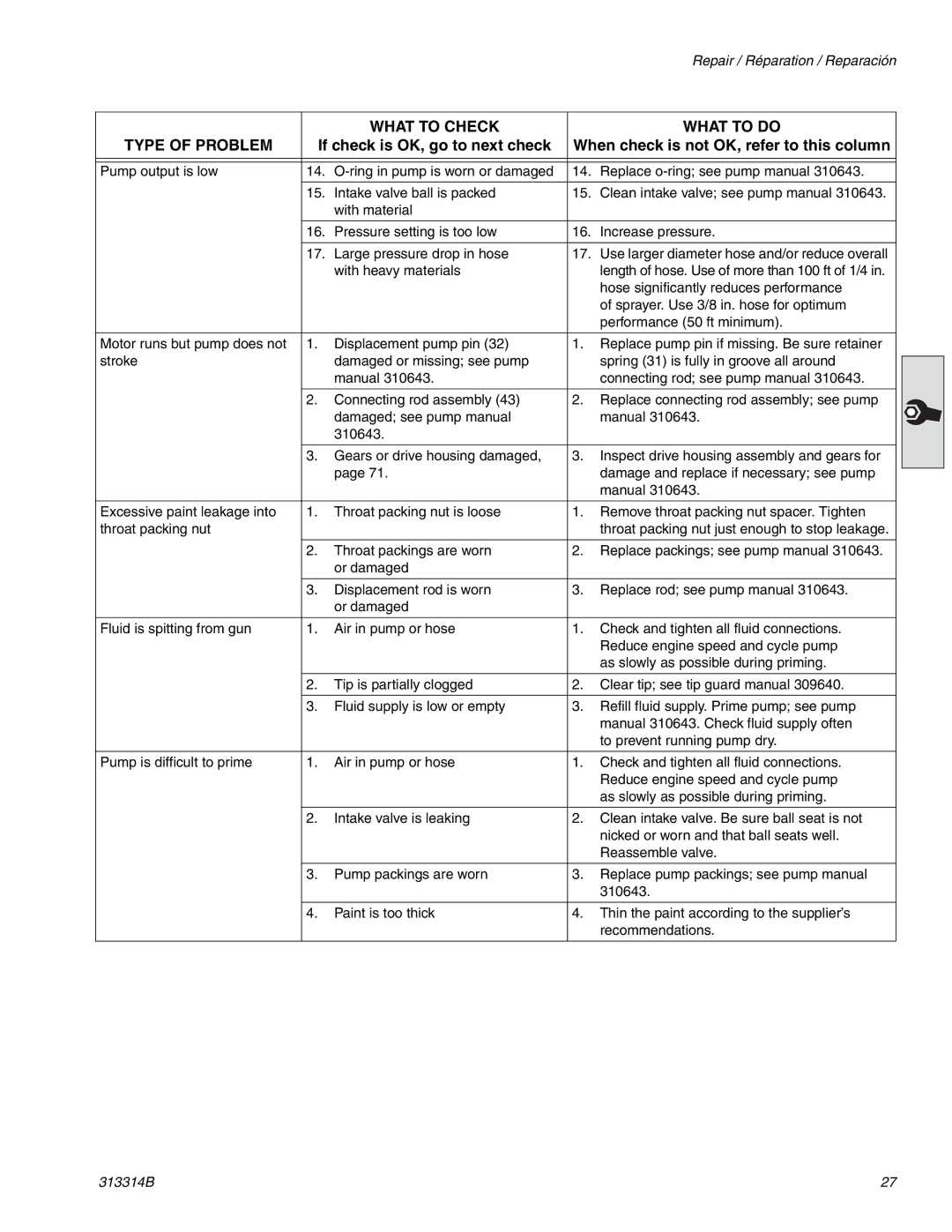

What to Check What to do Type of Problem

Performance 50 ft minimum

With heavy materials

Hose significantly reduces performance

Sprayer. Use 3/8 in. hose for optimum

Aller à la vérification suivante

Quoi Vérifier Quoi Faire

Type DE Problème

Consulter cette colonne

Aller à la vérification suivante Consulter cette colonne

Compruebe si existe alguna Cuando detecte la causa

Problema

Causa Medida a Tomar

De las siguientes causas Consulte esta columna

En la tuerca prensaestopas Está floja

Limpie la boquilla consulte el manual

Del protector de la boquilla

Électricité

Electrical

Alivie la presión, página

Problemas eléctricos

Instrucciones para observar los códigos de error

Avertissement

If check is OK, go to next check

Electrical Troubleshooting

Connections control board is not Digital display shows E=03

Detecting a pressure signal

Contacts are clean and secure

Sprayer does not run at all Check transducer or transducer

Step

Resistance Table

Check Motor Thermal Switch Unplug thermal

Is not correct, replace motor

Reconnect thermal device connector to control

Board socket. Connect power, turn sprayer on

Secure

Troubleshooting Procedure

Electric Motor Will Not Shut Off

YES

Replace

Motor Will Not Run

See . Do You have over AC volts?

Defective thermal device Connect a test

Control Board With GFI Filter Coil

Dépannage électrique

Si tout est normal après

Suivante Consulter cette colonne

Quoi Vérifier

Faire l’Essai de rotation essai au gros connecteur

Étape

Faire l’Essai de court-circuitage de champ essai au

Tableau des résistances

Aucun fonctionnement Laisser le pulvérisateur se refroidir

NON

Remplacer le bloc de commande

Arrêt impossible du moteur

Procédure de dépannage

Remplacer le

Refus du moteur de tourner

OUI NON

Remplacer ’interrupteur Si le moteur est chaud, laisser

Fil blanc du cordon d’alimentation

Consulte esta columna

Solución de problemas eléctricos

Causa Medida a Tomar

Realice una prueba de rotación Someta a una prueba

Paso

Realice una prueba breve de campo Someta a una

Tabla de resistencia

Inspeccione el interruptor térmico del motor

El motor elétrico no se apaga

Procedimiento de solución de problemas

Motor? Cambie el Tablero de

El motor no funciona

Repare

Cambie el Interruptor de alimentación

Negro al tablero Negro desde el cable eléctrico

Recubrimiento delantero

Removal / Retrait / Extracción

Front Shroud

Carénage avant

Recubrimiento delantero Recubrimiento trasero

Installation / Installation / Instalación

Front Shroud Rear Shroud

Carénage avant Carénage arrière

Diagram,

Quite el ojal y desconecte

Connectors

Disconnect transducer 86 and remove wiring grommet

Quite el tornillo de la puesta a tierra 26 y el cable

Ti13083a

Ti13083a Ti13084a Ti12999a Ti13087a

Installer le fil de terre et serrer la vis

Replace shroud 58 and tighten screws 13

Remettre en place le carénage 58 et serrer les vis 13 et

Quite la cubierta trasera página

115

Rotate new potentiometer

Ti13074a Ti12999a

86G

Use wrench to tighten Wiring protector Grommet 86G

Replace transducer wiring

Remettre en place

Brancher le fil du transducteur Remettre en place

Remettre en place Les carénages avant et arrière, voir

Motor

Avis

Replace pump, Lift retaining spring and replace pump pin

Replace rear shroud,

Replace pump rod covers Replace front shroud Tighten screws

Power cord

Flush pump Remove screws 31

Push up retaining spring Push pump pin 44 out

Débrancher le flexible

Installation / Installation / Instalación

De la bomba se enganche

Étendre la tige de piston de la pompe sur 1,5 po

Extienda la varilla del pistón 1.5 in. Aplique grasa

De bombeo en o dentro de la varilla de unión

102 Nm

Visser l’écrou de blocage

± 5 lb-pi 102 Nm

Arrière, voir

Colocar el

Replace rear shroud mounting bracket 49. Replace shroud,

Vuelva a colocar el Alojamiento del

Rodamiento Del recubrimiento Página

Parts / Pièces / Piezas

Ref. Part Description

Part Description Qty

Qty

Screw

Parts Filter / Pièces Filtre / Piezas Filtro

Wiring Diagram

Diagramme de câblage

Transductor

Diagrama de cableado

Interruptor Thermal Térmico Switch Potenciómetro

Motor

Fiche technique

Technical Data

Datos técnicos

11/2008

Warranty / Garantie / Garantía

Graco Headquarters Minneapolis

International Offices Belgium, Korea, China, Japan