Blade Tilt Stops

The table saw features stop bolts that stop the blade exactly at 45° and 90° during blade adjust- ments. The stops have been set at the factory and should require no adjustments, unless you notice that your cuts are not accurate.

Tools Needed | Qty |

90° Square | 1 |

Combo Square | 1 |

Wrench 12 & 13mm | 1 |

Hex Wrench 2.5mm | 1 |

Setting 90° Stop Bolt

1.DISCONNECT THE SAW FROM POWER!

2.Position the blade tilt to zero (see indicator on the front of the saw), and raise the blade several inches above the table.

3.Place a machinist’s square against the table and blade so it contacts the blade evenly from bottom to top. Make sure a blade tooth does not obstruct the placement of the square.

4.Tilt the blade to 20° to access the 90° stop bolt on the cabinet.

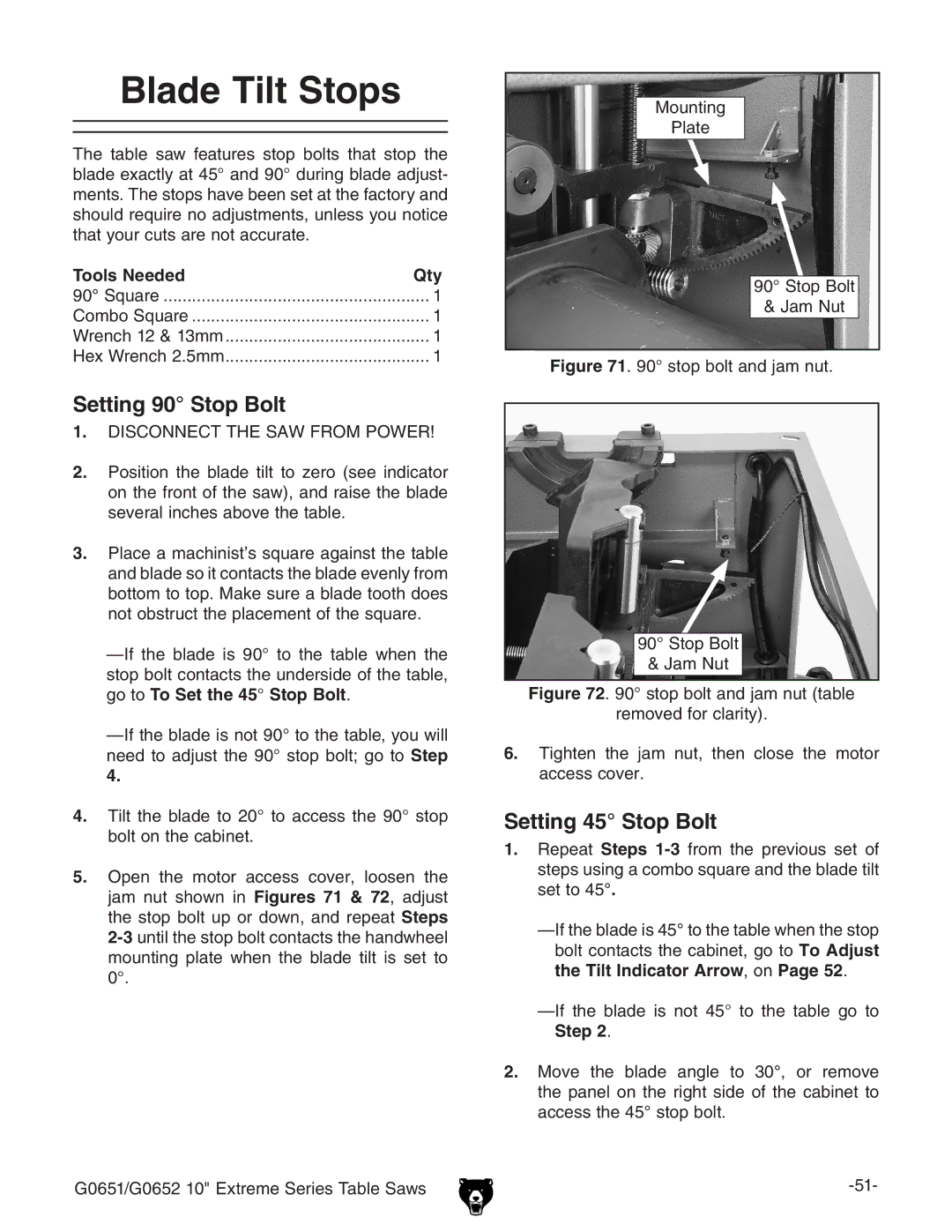

5.Open the motor access cover, loosen the jam nut shown in Figures 71 & 72, adjust the stop bolt up or down, and repeat Steps

G0651/G0652 10" Extreme Series Table Saws

Mounting

Plate

90° Stop Bolt

& Jam Nut

Figure 71. 90° stop bolt and jam nut.

90° Stop Bolt

& Jam Nut

Figure 72. 90° stop bolt and jam nut (table

removed for clarity).

6.Tighten the jam nut, then close the motor access cover.

Setting 45° Stop Bolt

1.Repeat Steps

Step 2.

2.Move the blade angle to 30°, or remove the panel on the right side of the cabinet to access the 45° stop bolt.