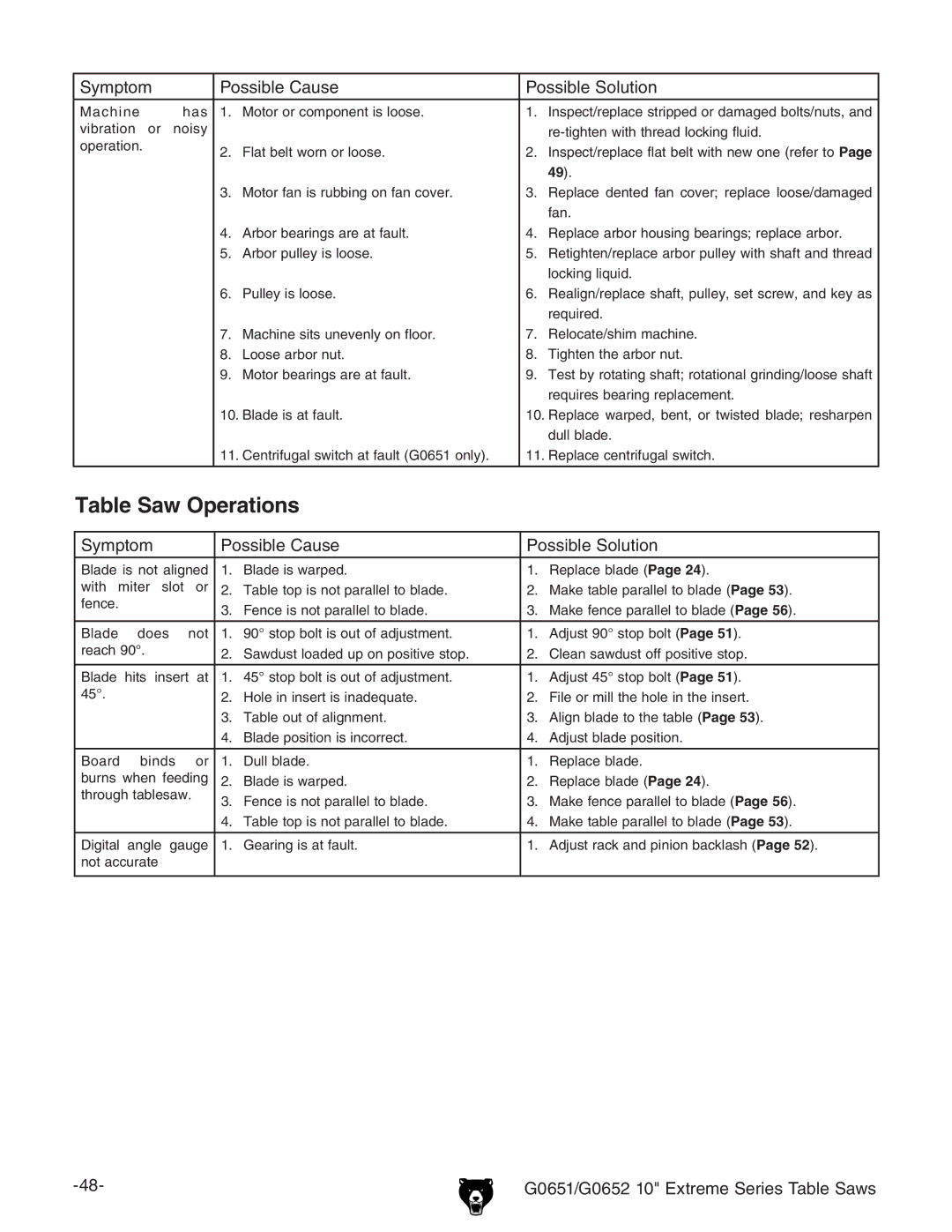

Symptom |

| Possible Cause | Possible Solution | ||

Machine | has | 1. | Motor or component is loose. | 1. | Inspect/replace stripped or damaged bolts/nuts, and |

vibration or | noisy |

|

|

| |

operation. |

| 2. | Flat belt worn or loose. | 2. | Inspect/replace flat belt with new one (refer to Page |

|

| ||||

|

|

|

|

| 49). |

|

| 3. | Motor fan is rubbing on fan cover. | 3. | Replace dented fan cover; replace loose/damaged |

|

|

|

|

| fan. |

|

| 4. | Arbor bearings are at fault. | 4. | Replace arbor housing bearings; replace arbor. |

|

| 5. | Arbor pulley is loose. | 5. | Retighten/replace arbor pulley with shaft and thread |

|

|

|

|

| locking liquid. |

|

| 6. | Pulley is loose. | 6. | Realign/replace shaft, pulley, set screw, and key as |

|

|

|

|

| required. |

|

| 7. | Machine sits unevenly on floor. | 7. | Relocate/shim machine. |

|

| 8. | Loose arbor nut. | 8. | Tighten the arbor nut. |

|

| 9. | Motor bearings are at fault. | 9. | Test by rotating shaft; rotational grinding/loose shaft |

|

|

|

|

| requires bearing replacement. |

|

| 10. Blade is at fault. | 10. Replace warped, bent, or twisted blade; resharpen | ||

|

|

|

|

| dull blade. |

|

| 11. Centrifugal switch at fault (G0651 only). | 11. Replace centrifugal switch. | ||

|

|

|

|

|

|

Table Saw Operations

Symptom |

|

| Possible Cause | Possible Solution | |||

Blade is not aligned | 1. | Blade is warped. | 1. | Replace blade (Page 24). | |||

with miter slot or | 2. | Table top is not parallel to blade. | 2. | Make table parallel to blade (Page 53). | |||

fence. |

|

|

| 3. | Fence is not parallel to blade. | 3. | Make fence parallel to blade (Page 56). |

|

|

|

| ||||

|

|

|

|

|

|

| |

Blade | does | not | 1. | 90° stop bolt is out of adjustment. | 1. | Adjust 90° stop bolt (Page 51). | |

reach 90°. |

|

| 2. | Sawdust loaded up on positive stop. | 2. | Clean sawdust off positive stop. | |

|

|

|

|

|

|

| |

Blade | hits insert | at | 1. | 45° stop bolt is out of adjustment. | 1. | Adjust 45° stop bolt (Page 51). | |

45°. |

|

|

| 2. | Hole in insert is inadequate. | 2. | File or mill the hole in the insert. |

|

|

|

| 3. | Table out of alignment. | 3. | Align blade to the table (Page 53). |

|

|

|

| 4. | Blade position is incorrect. | 4. | Adjust blade position. |

|

|

|

|

|

|

| |

Board | binds | or | 1. | Dull blade. | 1. | Replace blade. | |

burns when feeding | 2. | Blade is warped. | 2. | Replace blade (Page 24). | |||

through tablesaw. |

| 3. | Fence is not parallel to blade. | 3. | Make fence parallel to blade (Page 56). | ||

|

|

|

| ||||

|

|

|

| 4. | Table top is not parallel to blade. | 4. | Make table parallel to blade (Page 53). |

|

|

|

|

|

|

| |

Digital | angle | gauge | 1. | Gearing is at fault. | 1. | Adjust rack and pinion backlash (Page 52). | |

not accurate |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

G0651/G0652 10" Extreme Series Table Saws |