NOTICE

Models RED40 RED40ST

•What to do if you smell gas

Owner’s Manual

Homeowner Reference Information

A. Congratulations

Safety Alert Key

Table of Contents

Installer Guide

3 Maintenance and Service

15 Troubleshooting

14 Appliance Setup

= Contains updated information

13 Finishing

LIMITED LIFETIME WARRANTY

B. Limited Lifetime Warranty

WARRANTY COVERAGE

WARRANTY PERIOD

WARRANTY CONDITIONS

B. Limited Lifetime Warranty continued

WARRANTY EXCLUSIONS

This warranty is void if

1 Listing and Code Approvals

D. High Altitude Installations

A. Appliance Certification

B. Glass Specifications

Installation of Carbon Monoxide Detectors

2 Operating Instructions User Guide

A. Gas Fireplace Safety

B. Your Fireplace

C. Clear Space

D. Decorative Doors and Fronts

E. Fixed Glass Assembly

G. Before Lighting Fireplace

erate fireplace with fixed glass assembly removed

Final inspection by

H. Lighting Instructions IPI

FOR YOUR SAFETY READ BEFORE LIGHTING

LIGHTING INSTRUCTIONS IPI

I. After Fireplace is Lit

J.Frequently Asked Questions

Initial Break-inProcedure

•Some people may be sensitive to smoke and odors

A. Maintenance Tasks-Homeowner

3 Maintenance and Service

Glass Cleaning

Remote Control

Gasket Seal and Glass Assembly Inspection

B.Maintenance Tasks-QualifiedService Technician

Venting

Firebox

A. Typical Appliance System

Getting Started

Installer Guide

Figure 4.1 Typical System

D. Inspect Appliance and Components

B. Design and Installation Considerations

C.Tools and Supplies Needed

A. Selecting Appliance Location

5 Framing and Clearances

Figure 5.2 Appliance Locations RED40ST

1/2 IN

1/2 IN. C

C. Clearances

B. Constructing the Appliance Chase

MINIMUM FRAMING DIMENSIONS

Dimensions of Non-Combustibles

D. Mantel and Wall Projections

Combustible Mantels

Non-CombustibleMantels

A. Vent Termination Minimum Clearances

6 Termination Locations

Roof Pitch

H Min. Ft

V= VENT TERMINAL X = AIR SUPPLY INLET

= AREA WHERE TERMINAL IS NOT PERMITTED

Covered Alcove Applications

E. Vent Diagrams

7 Vent Information and Diagrams

A. Approved Pipe

B. Vent Table Key

Venting with 1 elbow

Top Vent - Horizontal Termination

V1 Minimum

H1 Maximum

Venting with 2 elbows

1. Top Vent - Horizontal Termination - continued

INSTALLED HORIZONTALLY

H1 + H2 Maximum

Venting with 3 elbows

1. Top Vent - Horizontal Termination

continued

H2 V2 H1 V1

Exhaust restrictor Instructions

Top Vent - Vertical Termination No Elbows

V = 3 ft Min. 1m, 50 ft. Max. 15.2 m

V2 H1 V1

Top Vent - Vertical Termination

Venting with 3 elbows

DIRECT VENT WITH 5 in. / 8 in. DIAMETER DVP PIPE

A. Pipe Clearances to Combustibles

8 Vent Clearances and Framing

B. Wall Penetration Framing

Between ceiling firestops

C. Install the Ceiling Firestop

Vaulted Ceiling Installation

D. Install Attic Insulation Shield

Flat Ceiling Installation

A. Appliance Preparation

9 Appliance Preparation

Setting the Fireplace into the Framing

B. Securing and Leveling the Appliance

WARNING! Risk of Fire! Prevent contact with

•Sagging or loose insulation

C. Active Convection Technology

A. Assemble Vent Sections

10 Installing Vent Pipe DVP Pipe

Pilot hole

B. Assemble Slip Sections

C. Secure The Vent Sections

D. Disassemble Vent Sections

E. Install Decorative Ceiling Components

G. Assemble and Install Storm Collar

F. Install Metal Roof Flashing

CAULK

CAUTION! Risk of Cuts, Abrasions or Flying Debris

H. Install Vertical Termination Cap

Figure 10.20 Venting Through the Wall

J. Install Horizontal Termination Cap

B. Gas Pressure

11 Gas Information

A. Fuel Conversion

•Ensure adequate ventilation

C. Gas Connection

B. IntelliFire Ignition System Wiring

A. Wiring Requirements

C. Optional Accessories Requirements

12 Electrical Information

REMOTE RECEIVER

Optional Remote Control Receiver Location

COLOR PRODUCED

D. Optional LED Lighting Circuit

SWITCH TRIPPED

F. Junction Box Installation

E. Electrical Service and Repair

G. Active Convection Blower Replacement

KNOCKOUT

FAN MOUNT FASTENER

SIDE BURNER SCREW

BLOWER TAB ON MOUNTING PLATE

SLOT ON BLOWER HOUSING

Figure 12.17. Remove Mounting Plate

Figure 12.18. Removed Mounting Plate

A. Splatter Guard

13 Finishing

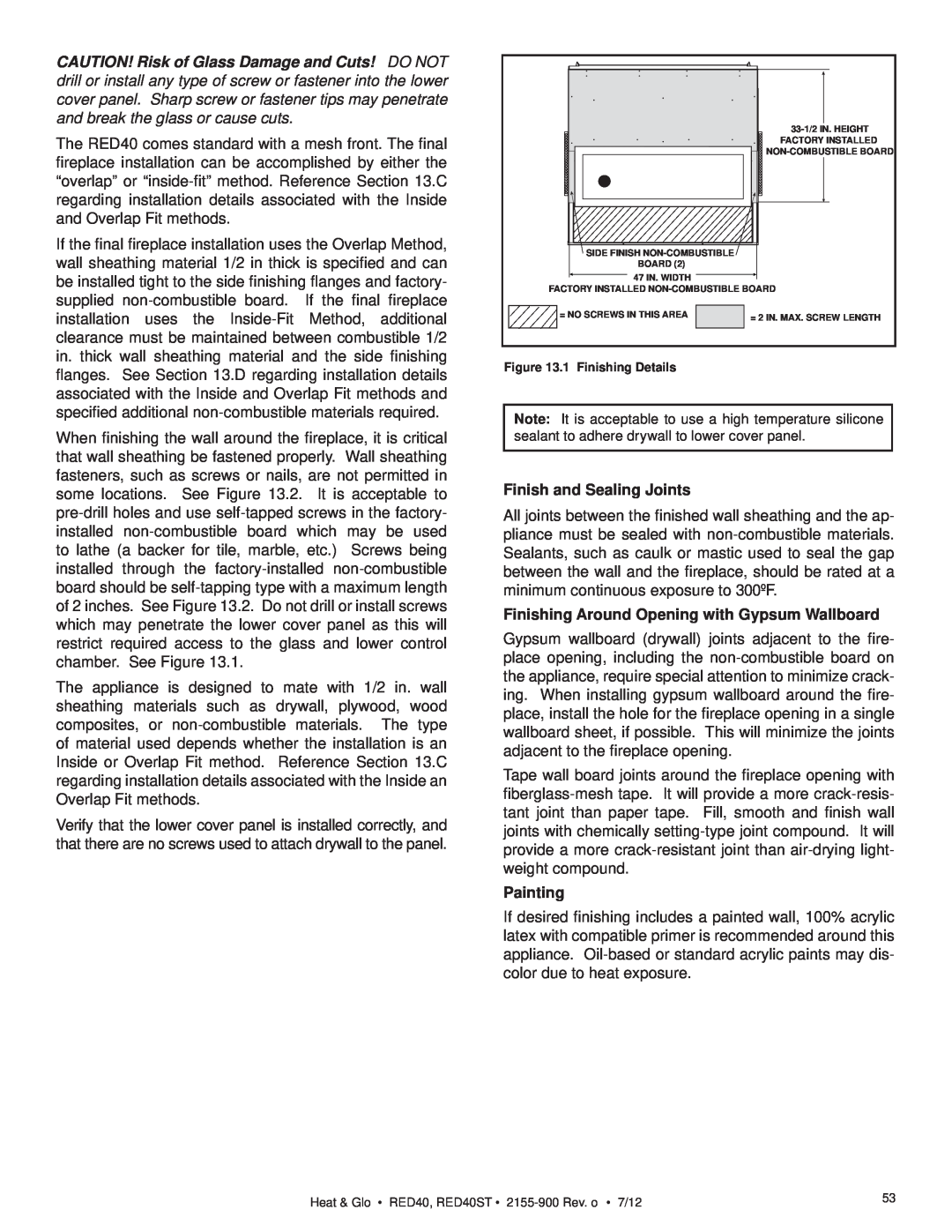

B. Framing and Finishing Instructions

Finishing Instructions

Finishing Around Opening with Gypsum Wallboard

Finish and Sealing Joints

Painting

Figure 13.1 Finishing Details

Dimensions of Combustibles

C. Mantel and Wall Projections

Figure 13.6 Framing and Framing Materials-RED40ST

D. Facing Material

Figure 13.5 Framing and Framing Materials-RED40

Figure 13.7 Overlap Fit Method

Non-CombustibleFinish Materials

0 - 1 inch thickness-OverlapFit Method

Figure 13.9 Inside Fit Method

0 Inches to 4 Inches Thick Inside Fit Method

42-3/4IN

13-1/8IN

ASSEMBLY

E. Mesh Fronts

MESH FRAME ASSEMBLY

Figure 13.11. Mesh Front Installation

A. Remove Fixed Glass Assembly

14 Appliance Setup

C. Clean the Appliance

D. Accessories

I. Install the Mesh

H. Fixed Glass Assembly

J. Air Shutter Setting

Removing Fixed Glass Assembly

A. IntelliFire Ignition System

15 Troubleshooting

Symptom

Possible Cause

IntelliFire Ignition System - continued

16 Reference Materials

A. Appliance Dimension Diagram

M N O P

Figure 16.2 Appliance Dimensions RED40ST

T R Q S

A F G

DVP-AS2

B. Vent Components Diagrams

Figure 16.2 DVP vent components

DVP-TRAP1

B. Vent Components Diagrams continued

DVP-TRAP2

DVP-TRAPK1

31 in

13 in

8-1/8in

206 mm

330 mm

PART NUMBER

Optional Wire Harness

DESCRIPTION

RED40

C. Service Parts

at Depot

Stocked

40 in Landscape See-ThruDV Fireplace

RED40ST

Service Parts List

#13 Control Assembly

#14 Valve Assembly

RED40,RED40ST

RED40, RED40ST

Service Parts

Stocked

15.3

#15 Base Pan No Lights with Media

15.1

15.2

15.1

15.2

15.3

15.4

Stocked at Depot

#16 Base Pan With Lights and Media

16.3

16.1

16.3

16.2

16.1

16.4

Porcelain or No refractory

#17 Base Pan No Lights or Media with

RED40-NNNNo lights, No Rock, No Refractory

RED40-NNPNo lights, No Rock, Porcelain

RED40ST-NNNNo lights, No Rock, No Refractory

Stocked at Depot

RED40ST-NNPNo lights, No Rock, Porcelain

RED40ST-NNGNo lights, No Rock, Granite

#20 Porcelain --No Media

#19 Granite --No Media

#21 Granite --With Media

#22 Porcelain --With Media

RED40ST

NOTES

D. Contact Information