Heat CONTROLLER, INC

Contents

Indoor Unit

Functions

Auto Wind

Operation Owoff Operation Mode Selection

Remote Controller

Fan Speed Selection

Product SpecificationsCooling Only

Power Supply 17Z,-W

Air Circulation

Oumw 1 ,260

Product SpecificationsCooling & Heating

Jzý, Installation plate

Indoor Unit

Tubing hole cover

9k, 12k 18k, 24k

Gas side

Outdoor Unit

Model DIM

Refrigeration Cycle Diagram

Cooling Only Models

Cooling & Heating Models

Camay a Heating

Heat

Evaporator I / \

Indoor Wiring Diagram

Indoor Wiring Diagram

MSS-012, MSS-018, MS18, MSS-024, MSF4424

Iroom

Outdoor Unit Cooling Only Models

9k, 12k

18k 24k

LO.a

12k 18k 24k

Time delay Safety Control

Cooling Operation Mode

Function of main control

Airflow Direction Control

Intake AIR Temp Setting TEMP. +1F

Auto Operation Electronic control mode

Setting TEMP. -10F

Modeo

MODE1rStart

MODE2 MODE3 MODE4 Modes

End

Soft Dry Operation Mode

Intake AIR TE

Selecting Low

OFF Compressor

Intake AIR Temp Setting TEMP. +60F

Setting Temp

Heating Operation Modeonly Heating Model

Indoor

Rý u

Pipe Temp

Defrost OFF

Defrost on

Cooling or Heating Mode with Sleep Mode Auto Control

Setting TEMP. -1F

Setting Temp

Forced Operation

Crank Case Heater Coil Controlonly Heating model

ICJ

Indoor

Outdoor

Display Function

Self-diagnosis Function

Buzzer Sound

Diagnosis

Installation

Is toxic when burned

When connecting refrigerant tubing

When servicing

Selection of the best location

Roof Top Installations

Piping length and the elevation

Indoor Unit Installation

Avoid areas where electrical wiring, conduits or

Wire or gas line can cause death or injury

Lower left and right side of Installation Plate

Piping and Drainage of Indoor Unit

Preparation of Pipings

Started Poo

113 H IW-0

Connection of Pipings

For right rear piping

Llj

5kgm39.8ft.ibs

For the left pipings

Insert the connecting cable into the indoor unit

Tape the tubing, drain hose and the connecting

Indoor unit installation

Installation plate. Engage the two hooks of the rear

Drain hose Taping

Connecting the pipings to the Outdoor unit

Connecting Pipings and the cable to Outdoor unit

Connection of the cable

Terminals and fasten the wire tightly with the fixing screw

2sanoev

Checking the Drainage

Connect the cable to the indoor unit

Attach the Grille onto the cabinet

Bwid

Forming the pipings

Page

Page

Settfemont of Outdoor Unit

Temperature, Pressure, Ampere Chan

Evaluation of theperformance

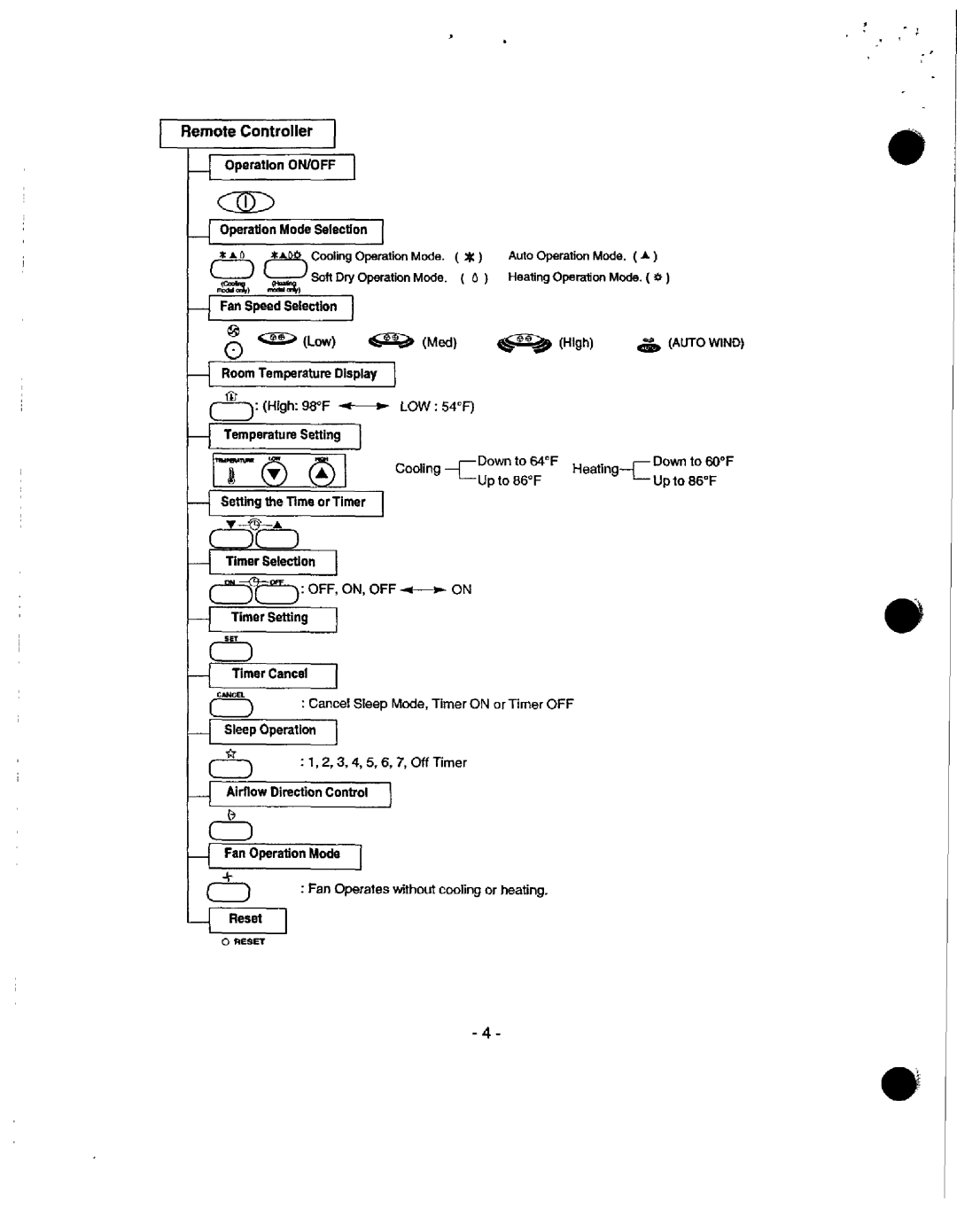

Name and Function-Remote Controller

MG OFF Timer Button

Sleep Mode Auto Button

Operation display

Qs Operation Mode Selection Button

Start/Stop Button

Be careful not to lose the clip when reassem- bling

Cooling & Heating

Remove the securing screws

To remove the Control Box

Remove 2 securing screws

Page

To remove the Grille from the Chassis

To remove the Control Box

To remove the Discharge Grille

To remove the Evaporator

Remove three screws fixing control box and motor

Unhook the tab on the left inside edge

To remove the Cross-Flow Fan

To remove the Fan Motor

Trouble analysis

Cycle Troubleshooting Guide

Cause of Trouble

Turn off Main Power Cý After 10 seconds

Connector related to CN-POWER Connector related to CN-FAN

Display PWB Assy Check Connector related to CN-DC/DC

Does beeping sound is made from the Indoor Unit?

Product Is not operate with the remote controller

R751K C711000PF Micom PIN Check Receiver Assy

Turn on Main Power

Compressor/Outdoor Fan are unable to drive

When Indoor Fan does not operate

When Vertical Louver does not operate

When a comunication error occurs

Operation indicator of Indoor unit blinks five times

Phenomena in case of connecting error

Indoor Unit

CN-UP/DOWN

CN-TH

CN-POWER RY-COMP

+0 , ý

Outdoor Unit

CN-TRANS CN-FAN

Voltage of Connectors according to Indoor Fan Speed

Electronic Control Device

Optional Function

Optional Function Model

Main PWB ASSYOutdoor Unit

1OK

18k, 24k

LDt ftn

ASM

LD2 LD4

Schematic Diagram

Page

BA ýJ

Plate Installation

Remote Controller

Heat OTY Remark

Parts Name Controller

Indoor Unit18k, 24k

Parts Name

Motor Assy Chassis Assy

7DDD \ , \

Tom, .ý M m mm

9k, 12k

Base Weld ASM Condenser Compressor ASM

Reversing Valve Reversing Coil

Front Panel Assy

Barrier

TOP Cover ASM Rear Panel

31 CAP

Capillary Final ASM HEATERCRANK-CASE1 Heat QTY Remark

Outdoor Unit18k

`Ty

L8k

MSS-018A MSH-018A

171

PWB ASSY, Main SH-CAPACITOR

Reversing Coil QTY Remark

Clamp Capacitor Controller Assy Check Valve CAPILLARY, Bent

CAPILLARY, Bent Panel Cover Control

29 CAP

PANEL, Rear

2021-0024

Remark R means service parts

ICJ No

9O2k

MSS-009B MSS-012B 2021-0001

Plate Installation Holder Tube Motor Assy Chassis Assy

MSS-0188 MSH-018B

2021-0001 2021-0074 2010-0003 2021-0069 2021-0005

FAN Assy Cross

Service VALVE1/4 Service VALVE112

GQ 21k

TOP Cover ASM

Capillary

Final ASM

HEATERCRANK-CASE

High Pressure S/W

Reversing Valve

2021-0024 I`J

FAN Motor

MSS-018A MSH-018A

SAT City Remark

Support Valve High Pressure S/W Reversing Coil

PWBASSY,MAIN

UTY Remark

2035-0004 2035-0006

2021-0021 2050-0001

Extra FAN Barrier ASM

Heat CONTROLLER, INC