Hitachi

Table of Contents

Xvi

Hazardous High Voltage

Safety Messages

Definitions and Symbols

General Precautions Read These First

Iii

Precautions for EMC Electromagnetic Compatibility

Index to Warnings and Cautions in This Manual

Installation Cautions for Mounting Procedures

Index to Warnings and Cautions in This Manual

Wiring Cautions for Electrical Practices

Vii

Powerup Test Caution Messages

Viii

L100 Inverter

General Warnings and Cautions

General Warnings and Cautions

GND lug

General Caution

Xii

NB576XA

Revision Comments Date of Issue Operation Manual No

Revisions

Page

Getting Started

Introduction

Main Features

L100 004 H F U

Inverter Specifications Label

Model Number Convention

Model-specific tables for 200V and 400V class inverters

L100 Inverter Specifications

200V Class Specifications

L100 inverters, 400V models

400V Class Specifications

Following table applies to all L100 inverters

General Specifications

General Specifications

Purpose of Motor Speed Control for Industry

What is an Inverter?

Introduction to Variable-Frequency Drives

Introduction to Variable-Frequency Drives

Torque and Constant Volts/Hertz Operation

Inverter Output to the Motor

Inverter Input and Three-Phase Power

Braking

Intelligent Functions and Parameters

Velocity Profiles

Shown at right uses two or more preset

L100 inverter is capable of sophisticated Speed

Speed Forward move Time Reverse move

Frequently Asked Questions

Getting Started

Getting Started

Inverter Mounting Installation

Unpacking and Inspection

Orientation to Inverter Features

Main Physical Features

Installation Inverter Mounting

Inverter Mounting Installation

Name Function

Motor Thermal switch

Basic System Description

Choosing a Mounting Location

Step-by-Step Basic Installation

L100

Model

Inverter Dimensions for Mounting

Dimensions are given in millimeters inches format

FAN

Dimensional drawings

FAN

Installation Inverter Mounting

Preparation for Wiring

Inverter Model Power Lines Signal Lines

Determination of Wire and Fuse Sizes

Motor Output Wiring Applicable KW/HP

Wiring the Inverter Input to a Power Supply

Screw Tightening Torque

Terminal Dimensions and Tightening Torque

Width mm

Wiring the Motor to the Inverter Output

Pre-test and Operational Precautions

Powerup Test

Goals for the Powerup Test

Powering the Inverter

Parameter Editing Controls

Using the Front Panel Keypad

Front Panel Introduction

Keys, Modes, and Parameters

Select Parameter Edit Parameter

Keypad Navigational Map

Keys until

Selecting Functions and Editing Parameters

Key twice

Key as needed

Speed command source setting

Press the 1 key three times

Monitoring Parameters with the Display

Running the Motor

Monitor Program

Powerup Test Observations and Summary

RunStop

Configuring3 Drive Parameters

Choosing a Programming Device

Number Access

Introduction

Introduction to Inverter Programming

Inverter Font Panel Keypad

Using Keypad Devices

Key and Indicator Legend

000

Other Keypad Programming Devices

Operational Modes

Using the PC Software DOP Plus

Programming with the DOP Plus

Parameter Monitoring Functions

Group Monitoring Functions

Function Run Range

Func Name Description Time Edit Units Code

Trip Event and History Monitoring

Group Main Profile Parameters

Group as shown to the right. The set

Func Name Description Time Edit

Function Run Defaults

Basic Parameter Settings

Group Standard Functions

Func Name Description Time

Analog Input Settings

Multi-speed Frequency Setting

Characteristics

Boost

Func Name Description Time Units Edit Code

Code

Gain

Edit Code

DC Braking Settings

Func Name

Frequency-related Functions

PID Control

AVR AC

Automatic Voltage Regulation AVR Function

AVR

ACC2

Second Acceleration and Deceleration Functions

DEC

ACC

Line

Restart Mode

Group Fine Tuning Functions

LVL

Electronic Thermal Overload Alarm Setting

THM

Const

Overload Restriction

Oload

Lock

Software Lock Mode

ADJ

Miscellaneous Settings

Carrier

Fmin

Init

Init SEL

Group Intelligent Terminal Functions

Input Terminal Configuration

IN-TM

Intelligent Input Terminal Overview

When assigned input transitions Off to On

Inverter is in Stop Mode

Events remain in history until Reset

On powerup, the inverter will not resume a

Uses terminal L for power supply return

Terminal OI is enabled for current input

Terminal O is enabled for voltage input uses

Terminal L for power supply return

OUT-TM

Output Terminal Configuration

Output Function Summary Table Option Terminal Function Name

Description

RUN

FA1

Analog Function Summary Table Option Terminal Function Name

ARV ACC

Output Function Adjustment Parameters

ARV DEC

OV PID

ADJ-OI

ADJ-O

Operations Monitoring

Operations and Monitoring

L100 Inverter

24V

Connecting to PLCs and Other Devices

Circuits

COM

Terminal Name Description Ratings

Specifications of Control and Logic Connections

Analog Logic Inputs Output Outputs

Input circuits

Using Intelligent Input Terminals

Forward Run/Stop and Reverse Run/Stop Commands

Input Description

Multi-Speed Select

State

Option Terminal Function Name

F01, A20 to A35

Use a switch between terminals JG

Jogging Command

Set the value 01terminal mode in A02 Run

Programmed jog frequency to the motor

Option Terminal Function Name Input Description Code

Two-stage Acceleration and Deceleration

Free-run Stop

Option Terminal Function Name Input Description Code Symbol

External Trip

Unattended Start Protection

Software Lock

Analog Input Current/Voltage Select

Symbol State

Reset Inverter

Anlg

PTC Thermistor Thermal Protection

Open

Motor

Run Signal

Using Intelligent Output Terminals

Option Terminal Function Name Output Description Code

Valid for outputs

Frequency Arrival Signal

OI L

Overload Advance Notice Signal

Output Deviation for PID Control

PID loop error is defined as

Magnitude absolute value of the differ

Ence between the Setpoint target value

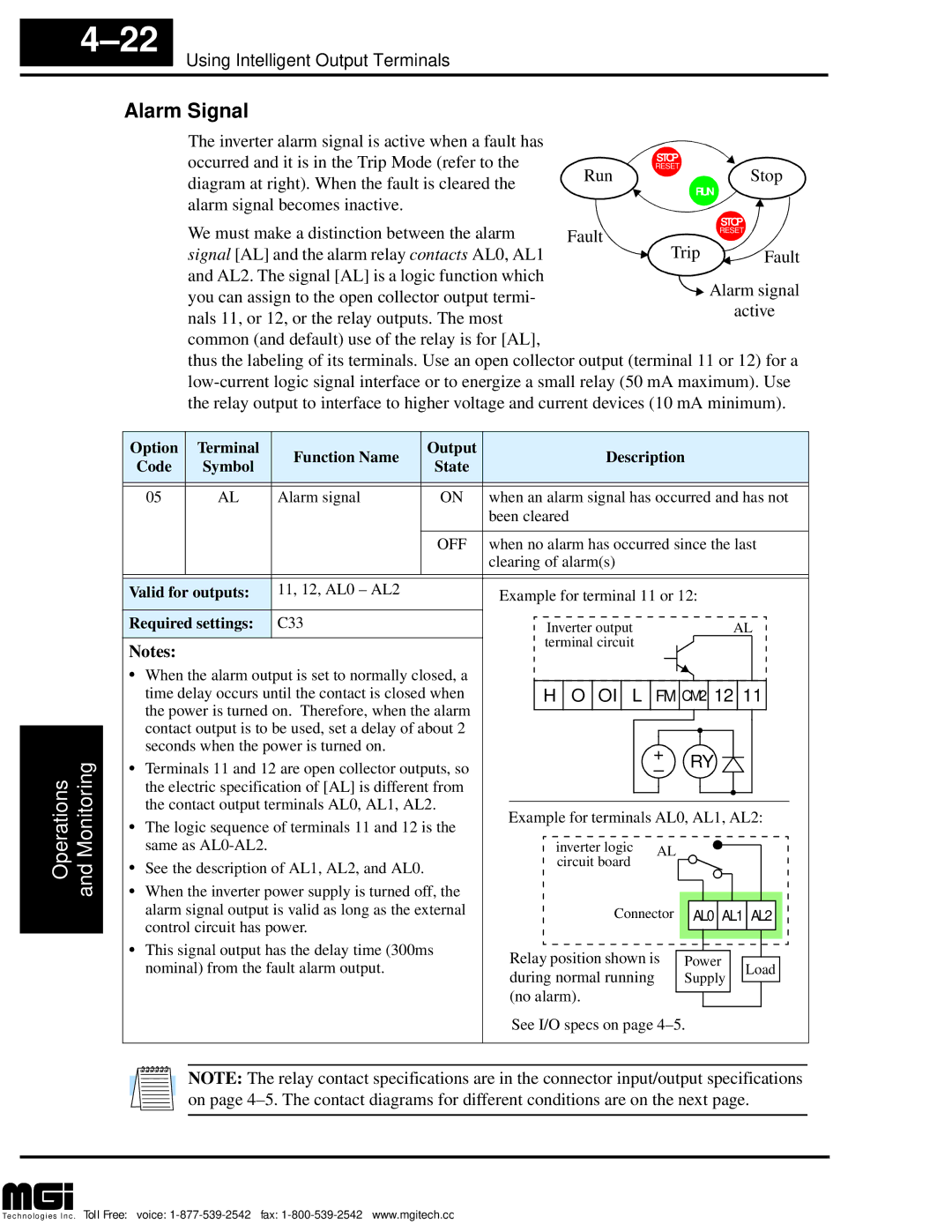

Diagram at right. When the fault is cleared Run

Alarm Signal

Alarm signal becomes inactive

We must make a distinction between the alarm Fault

When an alarm occurs

Analog Input Operation

Pulse-width modulation analog

Analog and Digital Monitor Output

+ 1∝ F

Analog and Digital Monitor Output

PID Loop Operation

Simultaneous Connections

Configuring the Inverter for Multiple Motors

Motor Control Accessories

Part No. Series See Name Europe

T1 T2 T3 RF noise filter AC reactor, or LCR filter

AC Reactors, Input Side

Component Descriptions

AC Reactors, Output Side

Meanline voltage

EMI Filter

RF Noise Filters Magnetic Choke

RF Noise Filter Capacitive

DC Link Choke

HRB1 HRB2 HRB3

Dynamic Braking

External resistor added Resistor only Model Number Without

Troubleshooting 6 and Maintenance

Safety Messages

Troubleshooting

General Precautions and Notes

Inspection Items

REV=U-W-V

Troubleshooting Tips

Symptom/condition Probable Cause Solution

Signal generating device

Previous Error #1

Inverter Fault Detection

Previous Error #2

Monitoring Trip Events, History, & Conditions

E01

Error Codes

E35

Error Name Causes Code

Restoring Factory Default Settings

Inspection Item Inspected Check for Cycle Criteria Method

Maintenance and Inspection

Monthly and Yearly Inspection Chart

Spare parts

Part description Symbol Quantity Used

Capacitor Life Curve

Operation for 12 hours / day

⋅ E1 ⋅

General Inverter Electrical Measurements

Pf0

⋅ E0 ⋅

Three-phase measurement diagram

Single-phase measurement diagram

Additional resistor

Inverter Output Voltage Measurement Techniques

Warranty Terms

Warranty

Glossary Bibliography

Glossary

Components you can install to decrease the level of EMI

Inverter DC braking feature stops the AC commutation to

Desirable it depends on the needs of the application

Percent of time a square wave of fixed frequency is on high

Watts as measurements of power

Unit of time. You can directly convert between horsepower

Generate 3-phase output to the motor

Harmful harmonics and transients on the input power

Complex number, where the resistance is the real part

Motor speed. See also error

Shaft are rotating and possesses angular momentum

Motor, and control motor speed according to the currently

Closely approximate a pure DC voltage source

Energy back to the power input mains

Desired value. Usually expressed as a percent +/- from

Nominal, motor regulation usually refers to its shaft speed

Signal generator usually attached to the motor shaft for

Power input of the motor. See also rotor

Earth Ground wires accompany the three Hot connections

Loads may be configured in a delta or Y configuration. a Y

Bibliography

Drive Parameter Settings Tables

Func. Code Name FE Europe

Parameter Settings for Keypad Entry

Main Profile Parameters

Standard Functions

Parameter Settings for Keypad Entry

For each

Fine Tuning Functions

Inverter B22 Overload restriction setting

Intelligent Terminal Functions

Func Name FE Europe

Parameter Settings for DOP/DRW/DOP Plus

Monitor Mode Parameters

Function Mode Setup

DCB SW OFF

DEC Line

DCB Wait

IPS Powr ALM

THM Char CRT

Oload Mode on

Oload LVL 01.75A

Oload Const

IN-TM CF2 USP

IN-TM CF1

IN-TM O/C-1

IN-TM O/C-2

Monitor

Init Mode TRP

Init SEL EUR USA

Init Debg OFF

Index

Index-2

Index-3

Index-4