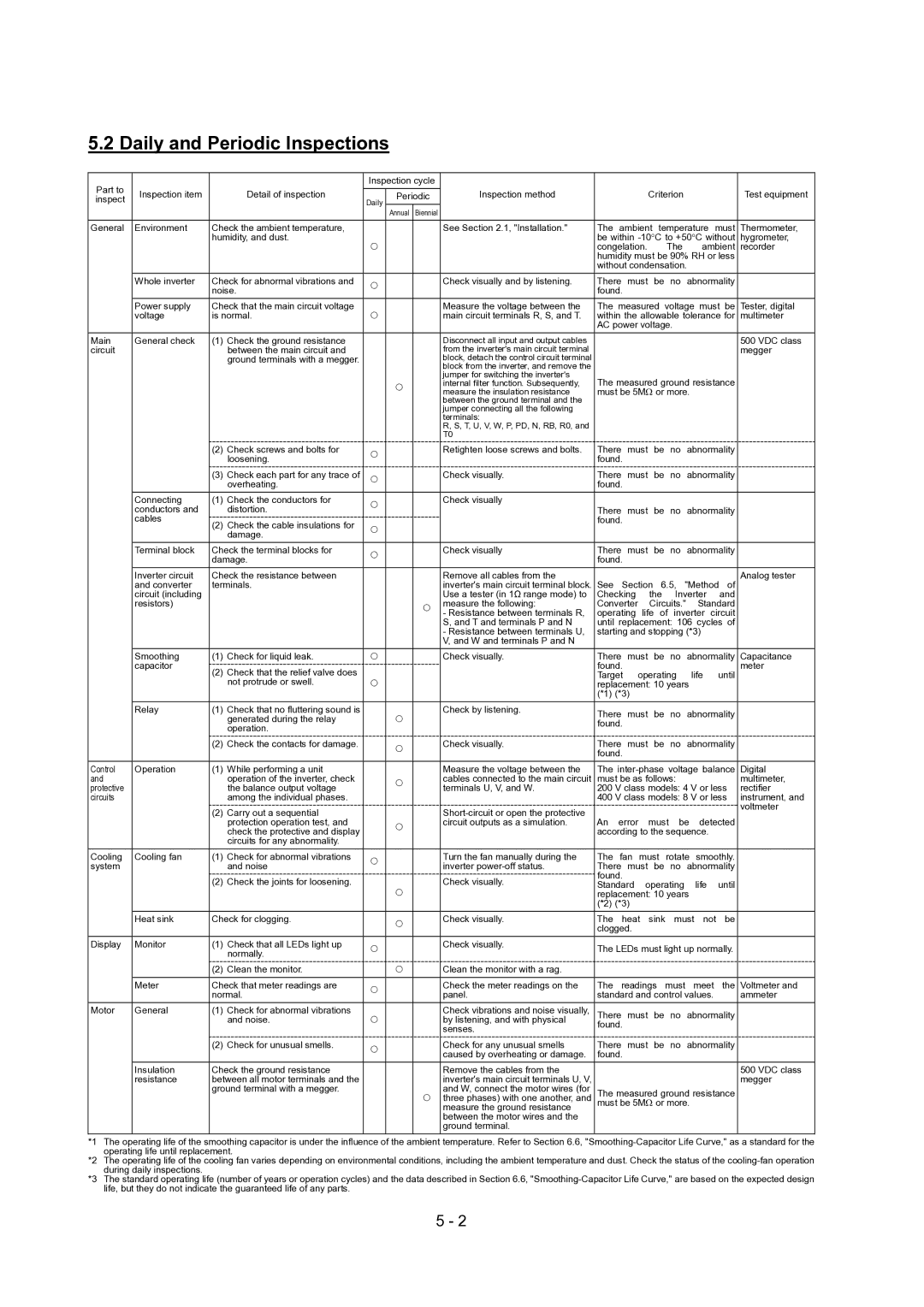

5.2 Daily and Periodic Inspections

Part to |

|

| Inspection cycle |

|

|

|

|

|

|

|

|

|

|

| ||

inspect | Inspection item | Detail of inspection | Daily | Periodic | Inspection method |

|

|

|

| Criterion |

|

|

| Test equipment | ||

|

|

|

| Annual | Biennial |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||||

General | Environment | Check the ambient temperature, |

|

|

| See Section 2.1, "Installation." | The ambient temperature must | Thermometer, | ||||||||

|

| humidity, and dust. |

|

|

|

| be within | hygrometer, | ||||||||

|

|

| { |

|

|

| congelation. |

| The |

| ambient | recorder | ||||

|

|

|

|

|

|

| humidity must be 90% RH or less |

| ||||||||

|

|

|

|

|

|

| without condensation. |

|

|

| ||||||

| Whole inverter | Check for abnormal vibrations and | { |

|

| Check visually and by listening. | There must be no abnormality |

| ||||||||

|

| noise. |

|

|

|

| found. |

|

|

|

|

|

|

| ||

| Power supply | Check that the main circuit voltage |

|

|

| Measure the voltage between the | The measured voltage must be | Tester, digital | ||||||||

| voltage | is normal. | { |

|

| main circuit terminals R, S, and T. | within the allowable tolerance for | multimeter | ||||||||

|

|

|

|

|

|

| AC power voltage. |

|

|

|

| |||||

Main | General check | (1) Check the ground resistance |

|

|

| Disconnect all input and output cables |

|

|

|

|

|

|

|

|

| 500 VDC class |

circuit |

| between the main circuit and |

|

|

| from the inverter's main circuit terminal |

|

|

|

|

|

|

|

|

| megger |

|

| ground terminals with a megger. |

|

|

| block, detach the control circuit terminal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| block from the inverter, and remove the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| jumper for switching the inverter's | The measured ground resistance |

| ||||||||

|

|

|

| { |

| internal filter function. Subsequently, |

| |||||||||

|

|

|

|

| measure the insulation resistance | must be 5MΩ or more. |

|

|

| |||||||

|

|

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

| between the ground terminal and the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| jumper connecting all the following |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| terminals: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| R, S, T, U, V, W, P, PD, N, RB, R0, and |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| T0 |

|

|

|

|

|

|

|

|

|

|

|

| (2) Check screws and bolts for | { |

|

| Retighten loose screws and bolts. | There | must | be | no | abnormality |

| ||||

|

| loosening. |

|

|

| found. |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| (3) Check each part for any trace of | { |

|

| Check visually. | There must be no abnormality |

| ||||||||

|

| overheating. |

|

|

|

| found. |

|

|

|

|

|

|

| ||

| Connecting | (1) Check the conductors for | { |

|

| Check visually |

|

|

|

|

|

|

|

|

|

|

| conductors and | distortion. |

|

|

| There must be no abnormality |

| |||||||||

|

|

|

|

|

| |||||||||||

| cables | (2) Check the cable insulations for | { |

|

|

| found. |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

| damage. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Terminal block | Check the terminal blocks for | { |

|

| Check visually | There | must | be | no | abnormality |

| ||||

|

| damage. |

|

|

| found. |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| Inverter circuit | Check the resistance between |

|

|

| Remove all cables from the | See Section 6.5, "Method of | Analog tester | ||||||||

| and converter | terminals. |

|

|

| inverter's main circuit terminal block. |

| |||||||||

| circuit (including |

|

|

|

| Use a tester (in 1Ω range mode) to | Checking |

| the | Inverter | and |

| ||||

| resistors) |

|

|

| { | measure the following: | Converter | Circuits." |

| Standard |

| |||||

|

|

|

|

| - Resistance between terminals R, | operating life of inverter circuit |

| |||||||||

|

|

|

|

|

| S, and T and terminals P and N | until replacement: 106 cycles of |

| ||||||||

|

|

|

|

|

| - Resistance between terminals U, | starting and stopping (*3) |

|

| |||||||

|

|

|

|

|

| V, and W and terminals P and N |

|

|

|

|

|

|

|

|

|

|

| Smoothing | (1) Check for liquid leak. | { |

|

| Check visually. | There must be no abnormality | Capacitance | ||||||||

| capacitor | (2) Check that the relief valve does |

|

|

|

| found. | operating | life | until | meter | |||||

|

|

|

|

| ||||||||||||

|

|

|

|

|

| Target |

| |||||||||

|

| not protrude or swell. | { |

|

|

| replacement: 10 years |

|

|

| ||||||

|

|

|

|

|

|

| (*1) (*3) |

|

|

|

|

|

|

| ||

| Relay | (1) Check that no fluttering sound is |

|

|

| Check by listening. | There | must | be | no | abnormality |

| ||||

|

| generated during the relay |

| { |

|

|

| |||||||||

|

|

|

|

| found. |

|

|

|

|

|

|

| ||||

|

| operation. |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| (2) Check the contacts for damage. |

| { |

| Check visually. | There | must | be | no | abnormality |

| ||||

|

|

|

|

|

| found. |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Control | Operation | (1) While performing a unit |

|

|

| Measure the voltage between the | The | Digital | ||||||||

and |

| operation of the inverter, check |

| { |

| cables connected to the main circuit | must be as follows: |

|

|

| multimeter, | |||||

protective |

| the balance output voltage |

|

| terminals U, V, and W. | 200 V class models: 4 V or less | rectifier | |||||||||

circuits |

| among the individual phases. |

|

|

|

| 400 V class models: 8 V or less | instrument, and | ||||||||

|

| (2) Carry out a sequential |

|

|

| An | error | must be | detected | voltmeter | ||||||

|

|

|

|

| ||||||||||||

|

| protection operation test, and |

| { |

| circuit outputs as a simulation. |

| |||||||||

|

| check the protective and display |

|

|

| according to the sequence. |

|

| ||||||||

|

|

|

|

|

|

|

| |||||||||

|

| circuits for any abnormality. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cooling | Cooling fan | (1) Check for abnormal vibrations | { |

|

| Turn the fan manually during the | The | fan | must | rotate | smoothly. |

| ||||

system |

| and noise |

|

| inverter | There must be no abnormality |

| |||||||||

|

|

|

|

| ||||||||||||

|

| (2) Check the joints for loosening. |

|

|

| Check visually. | found. | operating |

| life | until |

| ||||

|

|

|

|

|

|

| ||||||||||

|

|

|

|

| Standard |

|

| |||||||||

|

|

|

| { |

|

| replacement: 10 years |

|

|

| ||||||

|

|

|

|

|

|

| (*2) (*3) |

|

|

|

|

|

|

| ||

| Heat sink | Check for clogging. |

| { |

| Check visually. | The |

| heat | sink | must | not | be |

| ||

|

|

|

|

|

| clogged. |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Display | Monitor | (1) Check that all LEDs light up | { |

|

| Check visually. | The LEDs must light up normally. |

| ||||||||

|

| normally. |

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| (2) Clean the monitor. |

| { |

| Clean the monitor with a rag. |

|

|

|

|

|

|

|

|

|

|

| Meter | Check that meter readings are | { |

|

| Check the meter readings on the | The |

| readings must | meet | the | Voltmeter and | ||||

|

| normal. |

|

| panel. | standard and control values. |

| ammeter | ||||||||

|

|

|

|

|

| |||||||||||

Motor | General | (1) Check for abnormal vibrations | { |

|

| Check vibrations and noise visually, | There | must | be | no | abnormality |

| ||||

|

| and noise. |

|

| by listening, and with physical | found. |

|

|

|

|

|

|

| |||

|

|

|

|

|

| senses. |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| (2) Check for unusual smells. | { |

|

| Check for any unusual smells | There | must | be | no | abnormality |

| ||||

|

|

|

|

| caused by overheating or damage. | found. |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| Insulation | Check the ground resistance |

|

|

| Remove the cables from the |

|

|

|

|

|

|

|

|

| 500 VDC class |

| resistance | between all motor terminals and the |

|

|

| inverter's main circuit terminals U, V, |

|

|

|

|

|

|

|

|

| megger |

|

| ground terminal with a megger. |

|

|

| and W, connect the motor wires (for | The measured ground resistance |

| ||||||||

|

|

|

|

| { | three phases) with one another, and | must be 5MΩ or more. |

|

|

| ||||||

|

|

|

|

|

| measure the ground resistance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| between the motor wires and the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ground terminal. |

|

|

|

|

|

|

|

|

|

|

*1 The operating life of the smoothing capacitor is under the influence of the ambient temperature. Refer to Section 6.6,

*2 The operating life of the cooling fan varies depending on environmental conditions, including the ambient temperature and dust. Check the status of the

*3 The standard operating life (number of years or operation cycles) and the data described in Section 6.6,

5 - 2