Print-quality troubleshooting tools

Repetitive image defects ruler

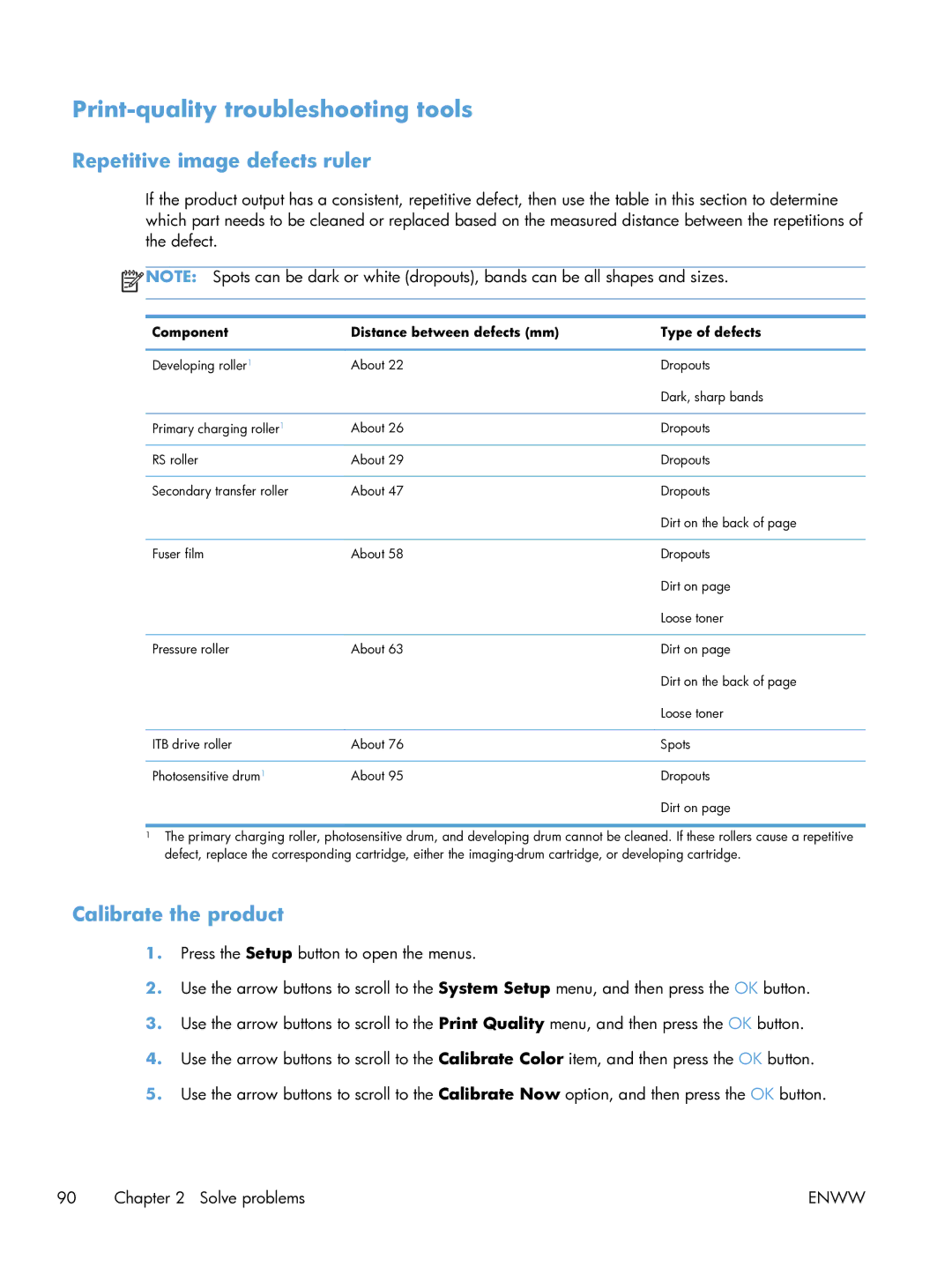

If the product output has a consistent, repetitive defect, then use the table in this section to determine which part needs to be cleaned or replaced based on the measured distance between the repetitions of the defect.

![]() NOTE: Spots can be dark or white (dropouts), bands can be all shapes and sizes.

NOTE: Spots can be dark or white (dropouts), bands can be all shapes and sizes.

Component | Distance between defects (mm) | Type of defects |

|

|

|

Developing roller1 | About 22 | Dropouts |

|

| Dark, sharp bands |

|

|

|

Primary charging roller1 | About 26 | Dropouts |

|

|

|

RS roller | About 29 | Dropouts |

|

|

|

Secondary transfer roller | About 47 | Dropouts |

|

| Dirt on the back of page |

|

|

|

Fuser film | About 58 | Dropouts |

|

| Dirt on page |

|

| Loose toner |

|

|

|

Pressure roller | About 63 | Dirt on page |

|

| Dirt on the back of page |

|

| Loose toner |

|

|

|

ITB drive roller | About 76 | Spots |

|

|

|

Photosensitive drum1 | About 95 | Dropouts |

|

| Dirt on page |

1The primary charging roller, photosensitive drum, and developing drum cannot be cleaned. If these rollers cause a repetitive defect, replace the corresponding cartridge, either the

Calibrate the product

1.Press the Setup button to open the menus.

2.Use the arrow buttons to scroll to the System Setup menu, and then press the OK button.

3.Use the arrow buttons to scroll to the Print Quality menu, and then press the OK button.

4.Use the arrow buttons to scroll to the Calibrate Color item, and then press the OK button.

5.Use the arrow buttons to scroll to the Calibrate Now option, and then press the OK button.

90 Chapter 2 Solve problems | ENWW |