5-2. Positive Temperature Coefficient (PTC) – Starter

1. Composition

(1)PTC (Positive Temperature Coefficient) is a

(2)The higher the temperature is, the higher the resistance value. These features are used as a starting device for the motor.

2. Role

(1)The PTC is attached to the sealed compressor and is used for starting the compressor motor.

(2)The compressor is a

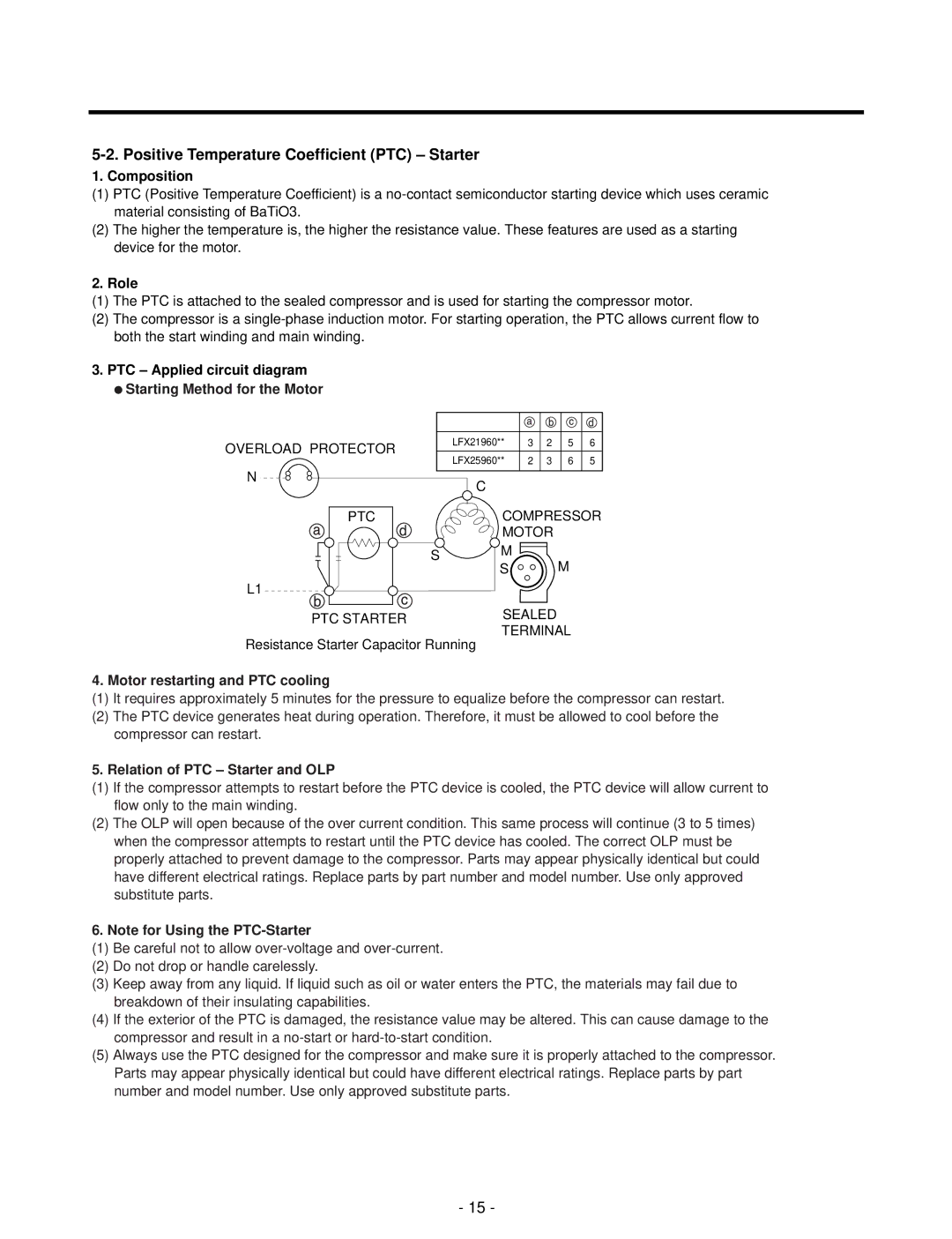

3.PTC – Applied circuit diagram

●Starting Method for the Motor

OVERLOAD PROTECTOR N ![]()

|

|

|

|

|

LFX21960** | 3 | 2 | 5 | 6 |

|

|

|

|

|

LFX25960** | 2 | 3 | 6 | 5 |

|

|

|

|

|

C

PTC

2

L1

COMPRESSOR

MOTOR

SM

S ![]() M

M

PTC STARTER | SEALED | |

TERMINAL | ||

Resistance Starter Capacitor Running | ||

|

4. Motor restarting and PTC cooling

(1)It requires approximately 5 minutes for the pressure to equalize before the compressor can restart.

(2)The PTC device generates heat during operation. Therefore, it must be allowed to cool before the compressor can restart.

5. Relation of PTC – Starter and OLP

(1)If the compressor attempts to restart before the PTC device is cooled, the PTC device will allow current to flow only to the main winding.

(2)The OLP will open because of the over current condition. This same process will continue (3 to 5 times) when the compressor attempts to restart until the PTC device has cooled. The correct OLP must be properly attached to prevent damage to the compressor. Parts may appear physically identical but could have different electrical ratings. Replace parts by part number and model number. Use only approved substitute parts.

6. Note for Using the

(1)Be careful not to allow

(2)Do not drop or handle carelessly.

(3)Keep away from any liquid. If liquid such as oil or water enters the PTC, the materials may fail due to breakdown of their insulating capabilities.

(4)If the exterior of the PTC is damaged, the resistance value may be altered. This can cause damage to the compressor and result in a

(5)Always use the PTC designed for the compressor and make sure it is properly attached to the compressor. Parts may appear physically identical but could have different electrical ratings. Replace parts by part number and model number. Use only approved substitute parts.

- 15 -