Section 3

SOFTWARE OPERATION |

3.1 SYNERGIC WELDING AND WORKPOINTS

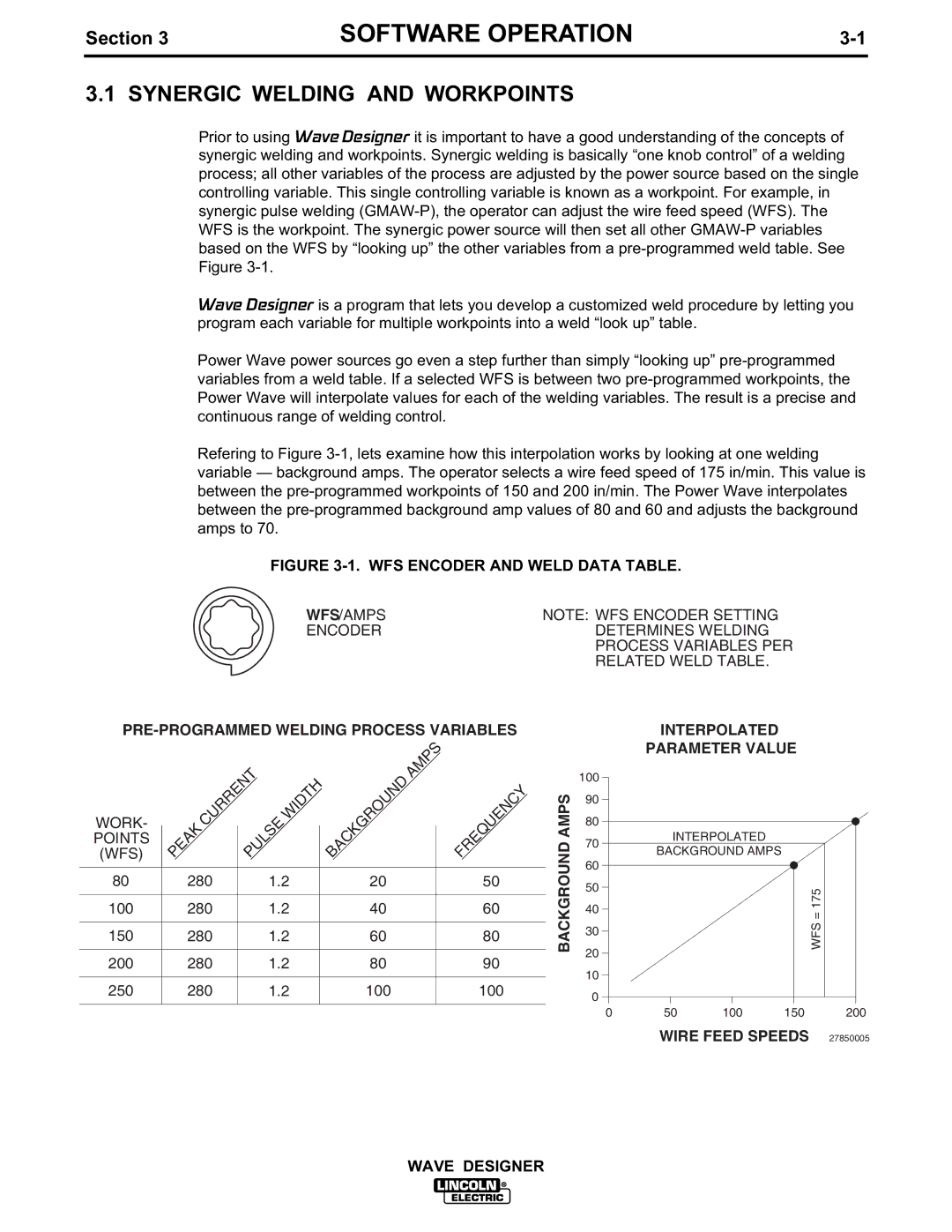

Prior to using Wave Designer it is important to have a good understanding of the concepts of synergic welding and workpoints. Synergic welding is basically “one knob control” of a welding process; all other variables of the process are adjusted by the power source based on the single controlling variable. This single controlling variable is known as a workpoint. For example, in synergic pulse welding

Wave Designer is a program that lets you develop a customized weld procedure by letting you program each variable for multiple workpoints into a weld “look up” table.

Power Wave power sources go even a step further than simply “looking up”

Refering to Figure

FIGURE 3-1. WFS ENCODER AND WELD DATA TABLE.

WFS/AMPS | NOTE: WFS ENCODER SETTING |

ENCODER | DETERMINES WELDING |

| PROCESS VARIABLES PER |

| RELATED WELD TABLE. |

|

| PULSE | WIDTH | BACKGROUND | AMPS | |

(WFS) |

|

|

| |||

WORK- |

|

|

|

|

|

|

POINTS |

|

|

|

|

|

|

|

|

|

|

|

| |

80 | 280 | 1.2 | 20 |

| 50 | |

|

|

|

|

|

| |

100 | 280 | 1.2 | 40 |

| 60 | |

|

|

|

|

|

| |

150 | 280 | 1.2 | 60 |

| 80 | |

|

|

|

|

|

| |

200 | 280 | 1.2 | 80 |

| 90 | |

|

|

|

|

|

| |

250 | 280 | 1.2 | 100 |

| 100 | |

|

|

|

|

|

|

|

BACKGROUND AMPS

100

90

80

70

60

50

40

30

20

10

0

0

INTERPOLATED

PARAMETER VALUE

| INTERPOLATED |

|

|

|

|

| ||

BACKGROUND AMPS |

|

|

|

|

| |||

|

|

|

|

|

| WFS = 175 |

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

50 | 100 | 150 | 200 | |||||

WIRE FEED SPEEDS | 27850005 | |||||||

WAVE DESIGNER