STT WAVE SHAPING PRINCIPLES | Appendix B |

B.3 STT (SURFACE TENSION TRANSFER)

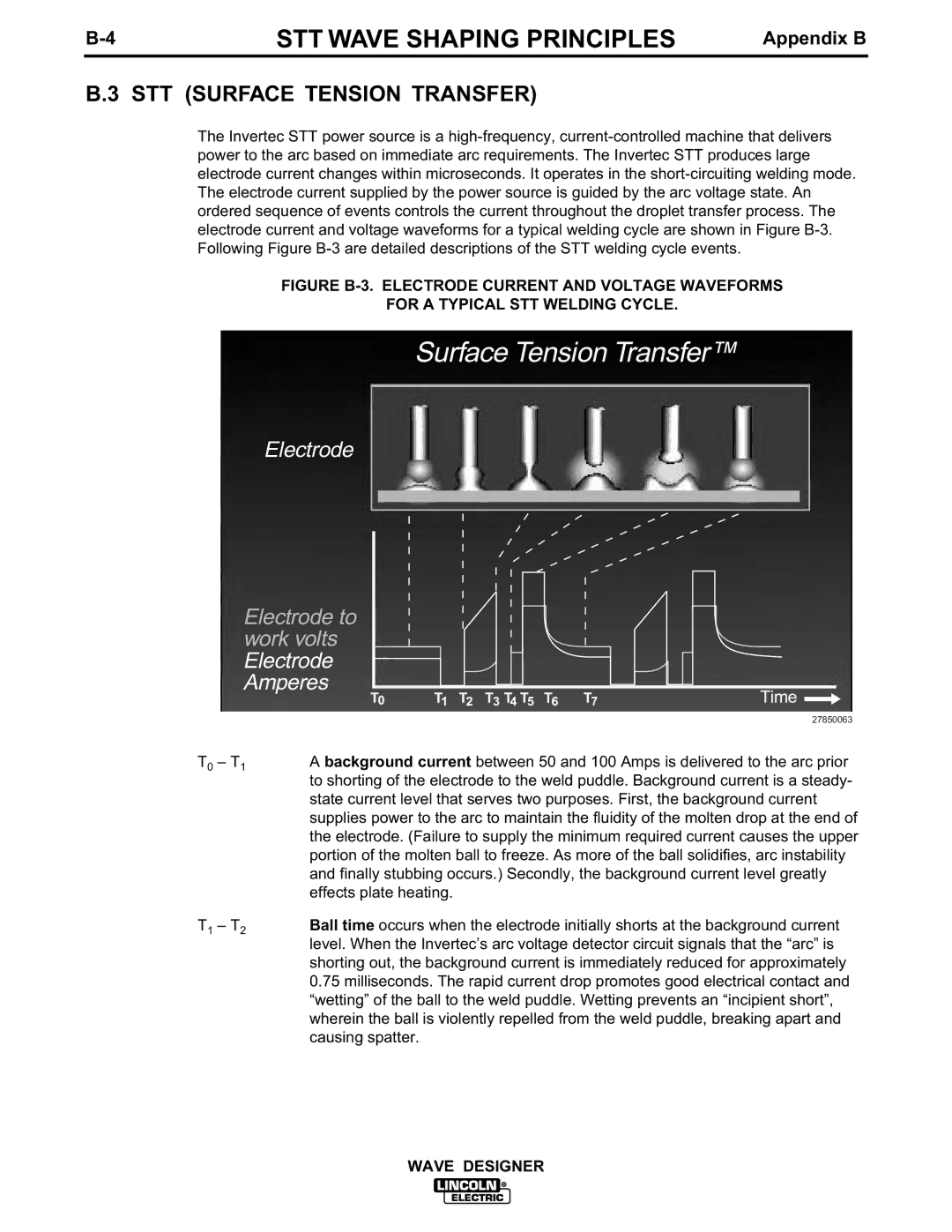

The Invertec STT power source is a

FIGURE B-3. ELECTRODE CURRENT AND VOLTAGE WAVEFORMS

FOR A TYPICAL STT WELDING CYCLE.

Surface Tension Transfer™

Electrode

Electrode to work volts Electrode Amperes

| T0 | T1 T2 T3 T4 T5 T6 T7 | Time |

|

|

| 27850063 |

T0 – T1 | A background current between 50 and 100 Amps is delivered to the arc prior | ||

| to shorting of the electrode to the weld puddle. Background current is a steady- | ||

| state current level that serves two purposes. First, the background current | ||

| supplies power to the arc to maintain the fluidity of the molten drop at the end of | ||

| the electrode. (Failure to supply the minimum required current causes the upper | ||

| portion of the molten ball to freeze. As more of the ball solidifies, arc instability | ||

| and finally stubbing occurs.) Secondly, the background current level greatly | ||

| effects plate heating. |

| |

T1 – T2 | Ball time occurs when the electrode initially shorts at the background current | ||

| level. When the Invertec’s arc voltage detector circuit signals that the “arc” is | ||

shorting out, the background current is immediately reduced for approximately

0.75milliseconds. The rapid current drop promotes good electrical contact and “wetting” of the ball to the weld puddle. Wetting prevents an “incipient short”, wherein the ball is violently repelled from the weld puddle, breaking apart and causing spatter.

WAVE DESIGNER