OPERATION |

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

PRACTICE

The best way of getting practice in the four skills that enable you to maintain:

1.Correct Welding Position.

2.Correct Way to Strike An Arc.

3.Correct Arc Length.

4.Correct Welding Speed.

is to spend a little more time on the following exercise.

Use the following: |

|

Mild Steel Plate: | 3/16” (4.8mm), or heavier. |

Electrode: | 1/8” (3.2mm) AWS 6011 |

| (Fleetweld® 180) |

Current Setting: |

Do the following:

1.Learn to strike the arc by scratching the electrode over the plate. Be sure the angle of the electrode is right and be sure to use both hands.

2.When you can strike an arc without sticking, prac- tice the correct arc length. Learn to distinguish it by its sound.

3.When you are sure that you can hold a short, crack- ling arc, start moving. Look at the molten puddle constantly, and look for the ridge where the metal solidifies.

4.Run beads on a flat plate. Run them parallel to the top edge (the edge farthest away from you). This gives you practice in running straight welds, and also, it gives you an easy way to check your progress. The 10th weld will look considerably bet- ter than the first weld. By constantly checking on your mistakes and your progress, welding will soon be a routine matter.

Common Metals

Most metals found around the farm or small shop are low carbon steel, sometimes referred to as mild steel. Typical items made with this type of steel include most sheet metal, plate, pipe and rolled shapes such as channels, angle irons and “I” beams. This type of steel can usually be easily welded without special precau- tions. Some steel, however, contains higher carbon. Typical applications include wear plates, axles, con- necting rods, shafts, plowshares and scraper blades.

These higher carbon steels can be welded successful- ly in most cases; however, care must be taken to follow proper procedures, including preheating the metal to be welded and, in some cases, carefully controlling the temperature during and after the welding process. For further information on identifying various types of steel and other metals, and for proper procedures for weld- ing them, we suggest you purchase a copy of “New Lessons in Arc Welding”.

Regardless of the type of metal being welded, in order to get a quality weld, it is important that it be free of oil, paint, rust or other contaminant's.

Types of Welds

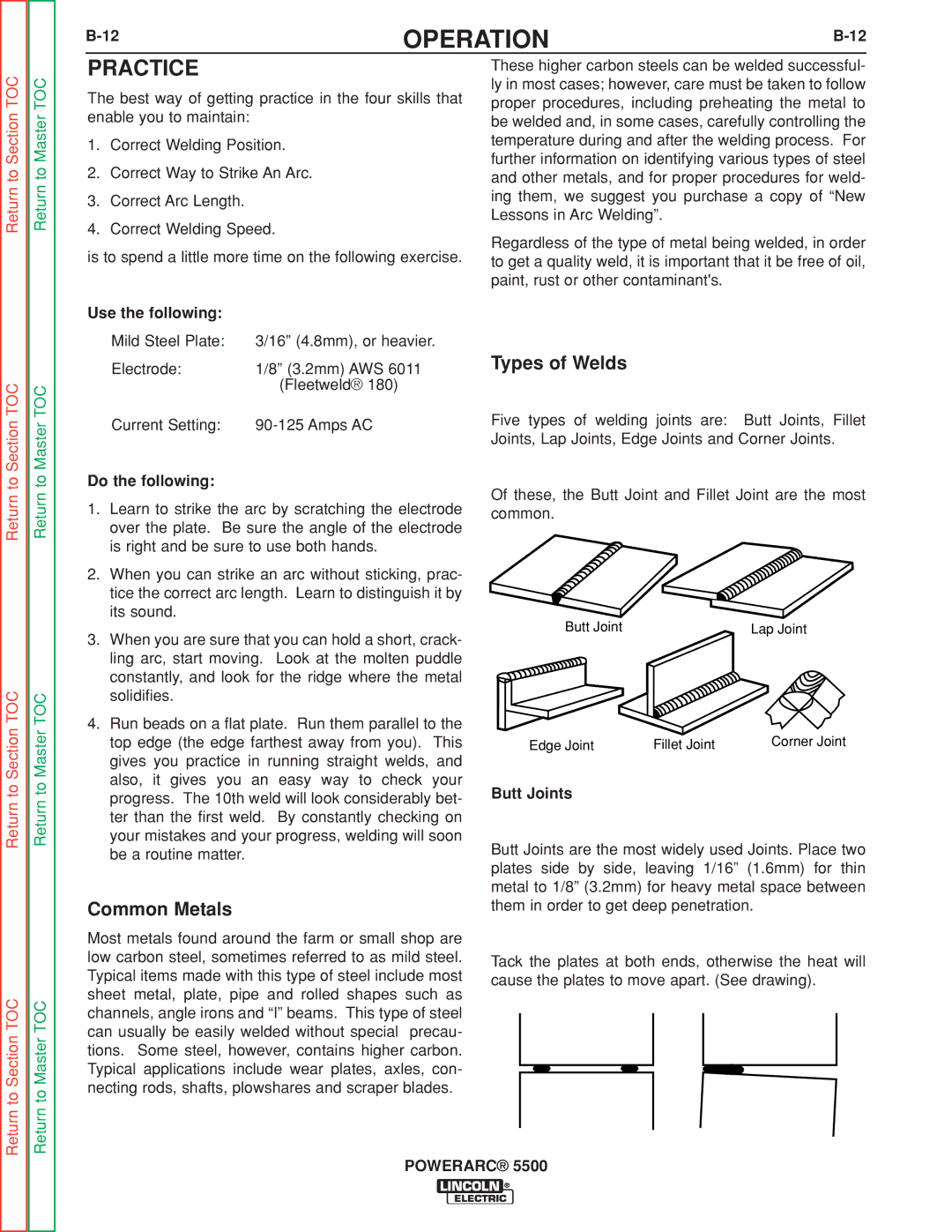

Five types of welding joints are: Butt Joints, Fillet Joints, Lap Joints, Edge Joints and Corner Joints.

Of these, the Butt Joint and Fillet Joint are the most common.

Butt Joint | Lap Joint |

Edge Joint | Fillet Joint | Corner Joint |

Butt Joints

Butt Joints are the most widely used Joints. Place two plates side by side, leaving 1/16” (1.6mm) for thin metal to 1/8” (3.2mm) for heavy metal space between them in order to get deep penetration.

Tack the plates at both ends, otherwise the heat will cause the plates to move apart. (See drawing).