MAINTENANCE |

Return to Master TOC

Return to Master TOC

GENERATOR/WELDER MAINTENANCE

STORAGE: Store the POWERARC® 5500 in clean, dry, protected areas.

CLEANING: Blow out the generator and controls periodically with low pressure air. Do this at least once a week in particularly dirty areas.

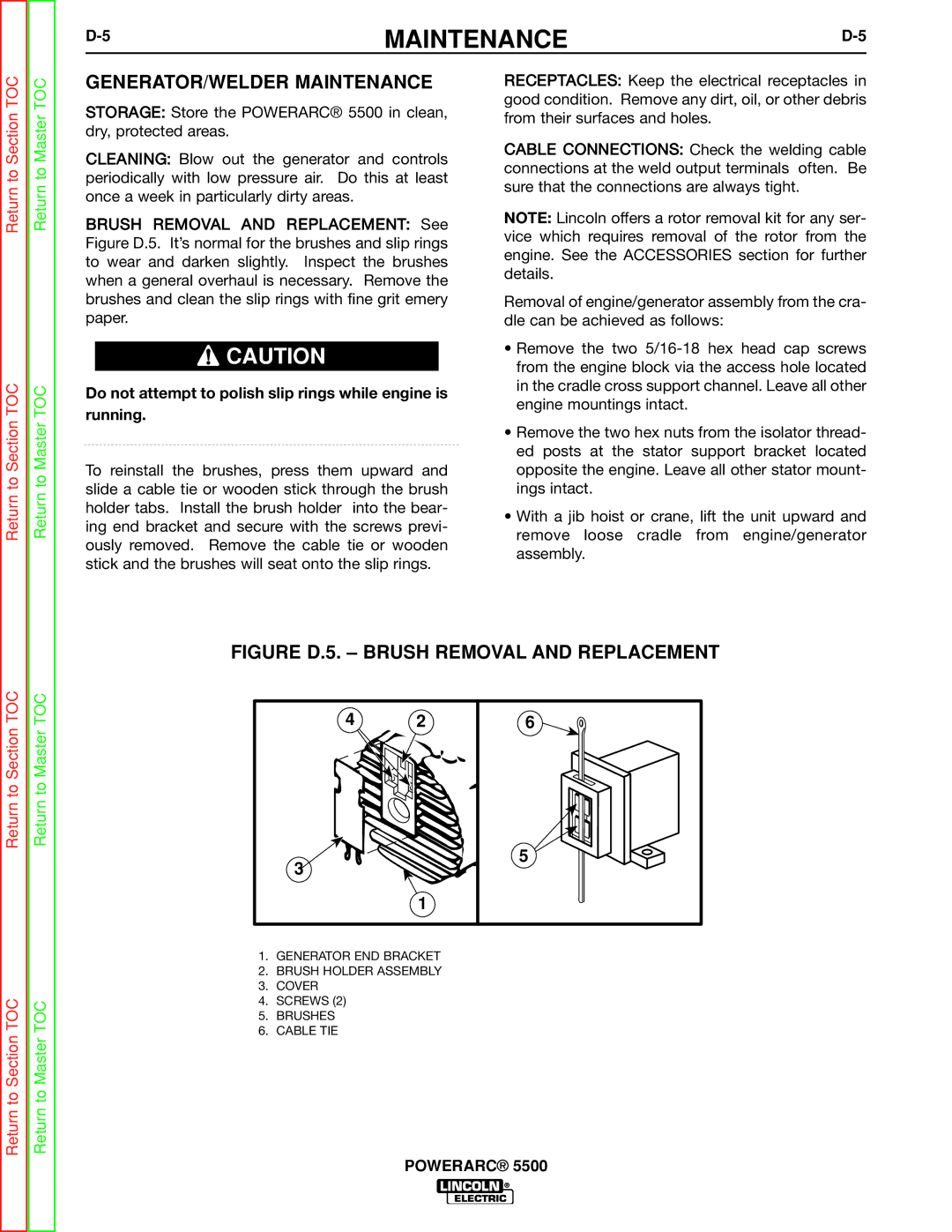

BRUSH REMOVAL AND REPLACEMENT: See Figure D.5. It’s normal for the brushes and slip rings to wear and darken slightly. Inspect the brushes when a general overhaul is necessary. Remove the brushes and clean the slip rings with fine grit emery paper.

![]() CAUTION

CAUTION

Do not attempt to polish slip rings while engine is running.

To reinstall the brushes, press them upward and slide a cable tie or wooden stick through the brush holder tabs. Install the brush holder into the bear- ing end bracket and secure with the screws previ- ously removed. Remove the cable tie or wooden stick and the brushes will seat onto the slip rings.

RECEPTACLES: Keep the electrical receptacles in good condition. Remove any dirt, oil, or other debris from their surfaces and holes.

CABLE CONNECTIONS: Check the welding cable connections at the weld output terminals often. Be sure that the connections are always tight.

NOTE: Lincoln offers a rotor removal kit for any ser- vice which requires removal of the rotor from the engine. See the ACCESSORIES section for further details.

Removal of engine/generator assembly from the cra- dle can be achieved as follows:

•Remove the two

•Remove the two hex nuts from the isolator thread- ed posts at the stator support bracket located opposite the engine. Leave all other stator mount- ings intact.

•With a jib hoist or crane, lift the unit upward and remove loose cradle from engine/generator assembly.

Return to Section TOC

Return to Section TOC

FIGURE D.5. – BRUSH REMOVAL AND REPLACEMENT

Return to Section TOC

Return to Master TOC

42

3 |

1

6 |

5 |

Return to Section TOC

Return to Master TOC

1.GENERATOR END BRACKET

2.BRUSH HOLDER ASSEMBLY

3.COVER

4.SCREWS (2)

5.BRUSHES

6.CABLE TIE