Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

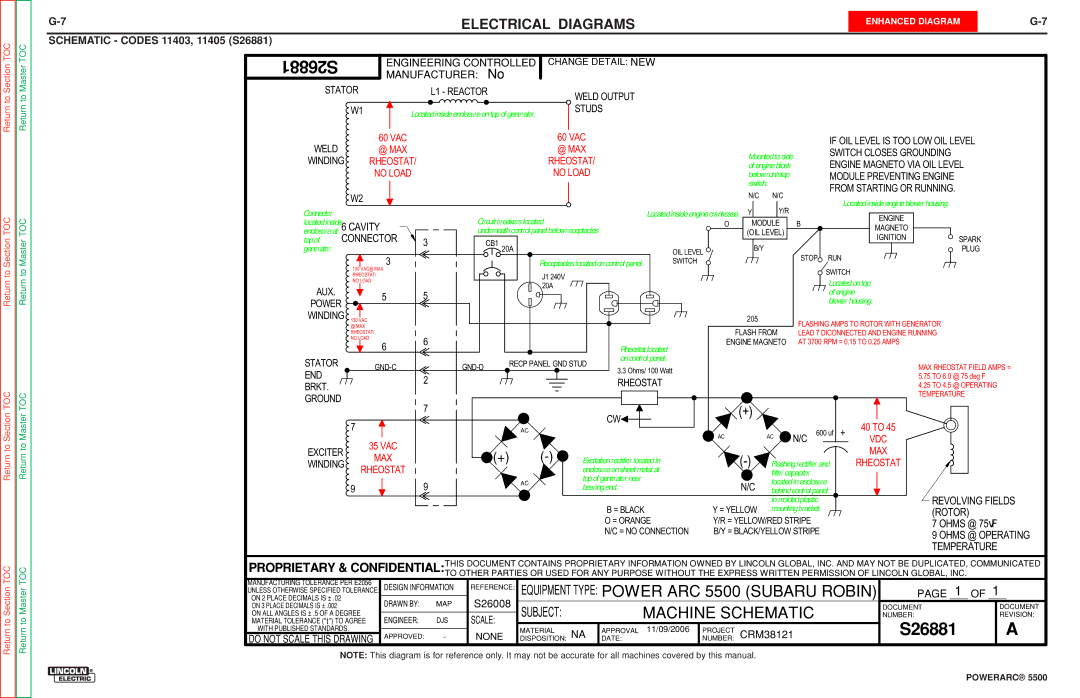

| ELECTRICAL DIAGRAMS |

| ENHANCED DIAGRAM | |||

SCHEMATIC - CODES 11403, 11405 (S26881) |

|

|

|

|

|

|

S26881 | ENGINEERING CONTROLLED CHANGE DETAIL: NEW |

|

|

| ||

MANUFACTURER: No |

|

|

|

| ||

|

|

|

|

| ||

STATOR |

| L1 - REACTOR | WELD OUTPUT |

|

|

|

|

|

|

|

|

| |

W1 | Locatedinsideenclosureontopof generator. | STUDS |

|

|

| |

|

|

|

|

| ||

WELD | 60 VAC |

| 60 VAC |

| IF OIL LEVEL IS TOO LOW OIL LEVEL |

|

@ MAX |

| @ MAX |

|

| ||

| Mounted to side | SWITCH CLOSES GROUNDING |

| |||

WINDING | RHEOSTAT/ |

| RHEOSTAT/ |

| ||

| ENGINE MAGNETO VIA OIL LEVEL |

| ||||

| of engineblock |

| ||||

| NO LOAD |

| NO LOAD |

| ||

|

| belowrun/stop | MODULE PREVENTING ENGINE |

| ||

|

|

|

| switch. | FROM STARTING OR RUNNING. |

|

W2 |

|

|

| N/C N/C |

| |

|

|

| Locatedinside engine blower housing. |

| ||

|

|

|

|

|

| |

Connector |

|

|

|

|

|

|

| Locatedinsideenginecrankcase. | Y | Y/R |

|

|

|

| ENGINE |

| ||

|

|

| Circuit breakerslocated |

|

|

|

|

|

|

| ||||||||

locatedinside |

|

|

|

|

| O | MODULE | B |

|

|

|

| ||||||

enclosureat | 6 CAVITY |

| underneathcontrol panel belowreceptacles |

|

|

| (OIL LEVEL) |

|

|

|

| MAGNETO |

| |||||

topof | CONNECTOR | 3 |

| CB1 20A |

|

|

|

|

|

|

|

|

|

|

| IGNITION | SPARK | |

generator. |

| 3 |

|

|

|

| OIL LEVEL |

| B/Y |

| STOP | RUN |

| PLUG | ||||

|

|

|

|

| Receptacleslocatedoncontrol panel. | SWITCH |

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| 130 VAC@ MAX |

|

|

|

|

|

|

|

|

|

|

| SWITCH |

|

| ||

|

| RHEOSTAT/ |

|

|

| J1 240V |

|

|

|

|

|

|

|

|

| |||

|

| NO LOAD |

|

|

|

|

|

|

|

|

|

|

| Locatedontop |

| |||

|

|

|

|

| 20A |

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

AUX. |

| 5 | 5 |

|

|

|

|

|

|

|

|

|

|

| of engine |

|

| |

POWER |

|

|

|

|

|

|

|

|

|

|

| blower housing. |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

WINDING | 130 VAC |

|

|

|

|

|

|

|

| 205 |

| FLASHING AMPS TO ROTOR WITH GENERATOR | ||||||

|

| @ MAX |

|

|

|

|

|

|

| FLASH FROM | ||||||||

|

| RHEOSTAT/ |

|

|

|

|

|

|

| LEAD 7 DICONNECTED AND ENGINE RUNNING | ||||||||

|

| NO LOAD | 6 |

|

|

|

|

|

| ENGINE MAGNETO AT 3700 RPM = 0.15 TO 0.25 AMPS |

| |||||||

|

| 6 |

|

|

|

| Rheostat located |

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

STATOR |

|

| RECP PANEL GND STUD | oncontrol panel. |

|

|

|

|

|

|

|

|

| MAX RHEOSTAT FIELD AMPS = | ||||

|

| 3.3 Ohms/ 100 Watt |

|

|

|

|

|

|

|

|

| |||||||

END |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| 2 |

|

|

|

|

|

|

|

|

|

|

|

|

| 5.75 TO 6.0 @ 75 deg F | ||

|

|

|

|

|

| RHEOSTAT |

|

|

|

|

|

|

|

|

| |||

BRKT. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4.25 TO 4.5 @ OPERATING | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

GROUND |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TEMPERATURE | |

| 7 |

|

|

|

|

|

| (+) |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| CW |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

| 7 |

|

|

|

|

|

|

|

|

|

|

|

|

| 40 TO 45 |

| |

|

|

|

| AC |

|

|

|

| AC |

|

| N/C | 600 uf | + |

| |||

|

| 35 VAC |

|

|

|

|

|

|

|

| AC | VDC |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

EXCITER |

|

|

|

|

|

|

|

|

|

|

|

|

|

| MAX |

| ||

MAX |

|

|

|

| Excitationrectifier locatedin |

|

|

|

|

|

|

|

| |||||

WINDING |

|

|

|

|

|

| Flashing rectifier and |

| RHEOSTAT |

| ||||||||

RHEOSTAT |

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

| enclosureonsheet metal at |

|

|

| filter capacitor |

|

|

|

|

| |||

|

|

|

|

|

|

| topof generator near |

|

|

|

|

|

|

|

| |||

|

|

| 9 |

| AC |

|

|

| N/C | locatedinenclosure |

|

|

|

| ||||

|

| 9 |

|

| bearingend. |

|

|

|

|

|

| |||||||

|

|

|

|

|

|

| behindcontrol panel |

|

|

|

| |||||||

|

|

|

|

|

|

|

| B = BLACK |

| Y = YELLOW | inmoldedplastic |

|

|

| REVOLVING FIELDS | |||

|

|

|

|

|

|

|

|

| mountingbracket. |

|

|

| (ROTOR) | |||||

|

|

|

|

|

|

|

| O = ORANGE |

| Y/R = YELLOW/RED STRIPE |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

| 7 OHMS @ 75vF | |||||

|

|

|

|

|

|

|

| N/C = NO CONNECTION | B/Y = BLACK/YELLOW STRIPE |

|

|

| 9 OHMS @ OPERATING | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| TEMPERATURE |

PROPRIETARY & CONFIDENTIAL:THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OWNED BY LINCOLN GLOBAL, INC. AND MAY NOT BE DUPLICATED, COMMUNICATED TO OTHER PARTIES OR USED FOR ANY PURPOSE WITHOUT THE EXPRESS WRITTEN PERMISSION OF LINCOLN GLOBAL, INC.

MANUFACTURING TOLERANCE PER E2056 | DESIGN INFORMATION | REFERENCE: | EQUIPMENT TYPE: | POWER ARC 5500 (SUBARU ROBIN) | 1 | 1 | |||||

UNLESS OTHERWISE SPECIFIED TOLERANCE: | |||||||||||

ON 2 PLACE DECIMALS IS ± .02 |

|

| S26008 |

|

| PAGE ___ OF ___ | |||||

DRAWN BY: | MAP |

|

| ||||||||

ON 3 PLACE DECIMALS IS ± .002 | SUBJECT: |

|

| MACHINE SCHEMATIC | DOCUMENT |

| DOCUMENT | ||||

ON ALL ANGLES IS ± .5 OF A DEGREE |

|

|

|

|

| NUMBER: |

| REVISION: | |||

ENGINEER: | DJS | SCALE: |

|

|

|

|

|

|

|

| |

MATERIAL TOLERANCE ("t") TO AGREE |

|

|

|

|

| S26881 |

| A | |||

WITH PUBLISHED STANDARDS. |

|

|

| MATERIAL | NA | APPROVAL | 11/09/2006 | PROJECT |

| ||

|

|

|

| ||||||||

DO NOT SCALE THIS DRAWING | APPROVED: | - | NONE | DISPOSITION: | DATE: |

| NUMBER: CRM38121 |

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual.