Return to Section TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR |

RHEOSTAT REMOVAL AND REPLACEMENT PROCEDURE (continued)

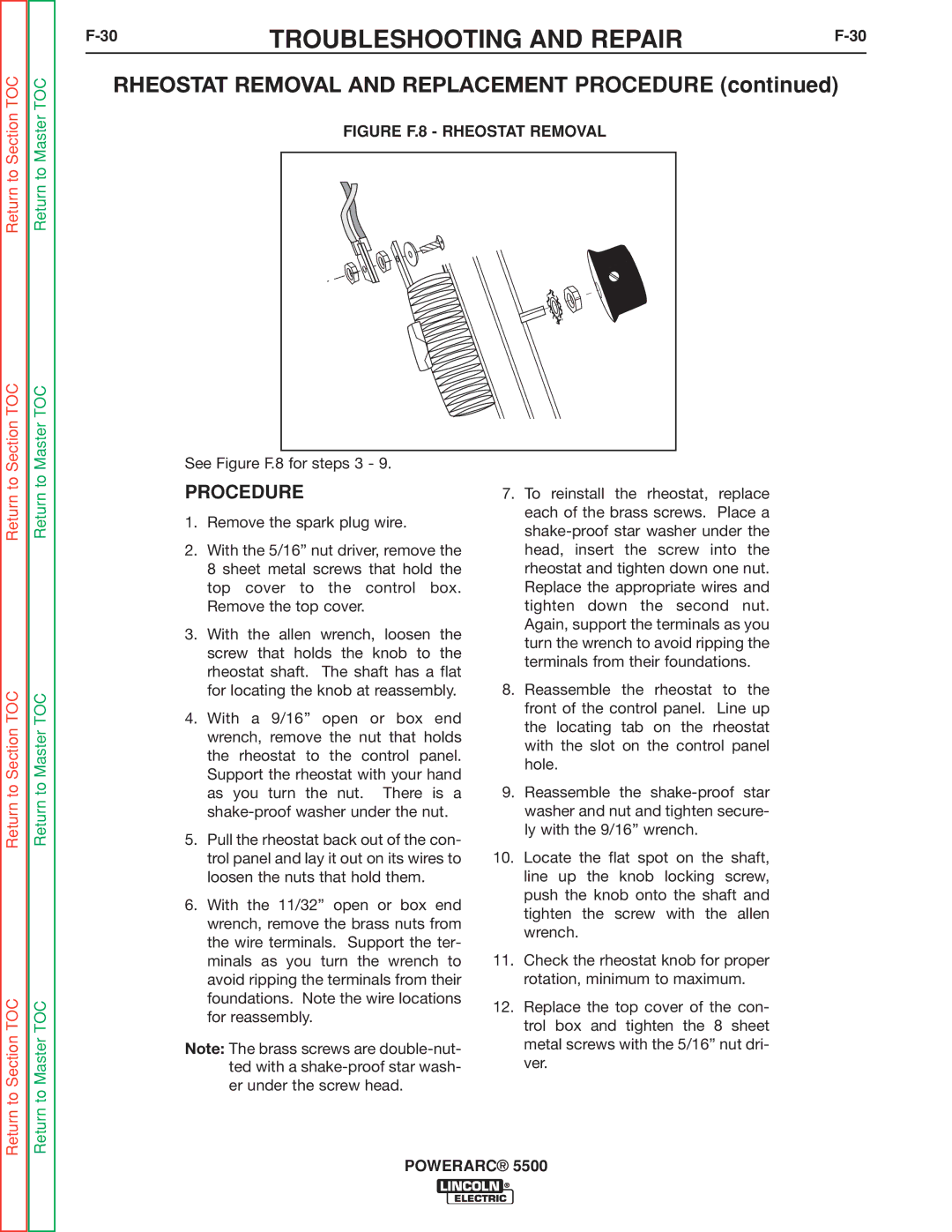

FIGURE F.8 - RHEOSTAT REMOVAL

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

See Figure F.8 for steps 3 - 9.

PROCEDURE

1.Remove the spark plug wire.

2.With the 5/16” nut driver, remove the 8 sheet metal screws that hold the top cover to the control box. Remove the top cover.

3.With the allen wrench, loosen the screw that holds the knob to the rheostat shaft. The shaft has a flat for locating the knob at reassembly.

4.With a 9/16” open or box end wrench, remove the nut that holds the rheostat to the control panel. Support the rheostat with your hand as you turn the nut. There is a

5.Pull the rheostat back out of the con- trol panel and lay it out on its wires to loosen the nuts that hold them.

6.With the 11/32” open or box end wrench, remove the brass nuts from the wire terminals. Support the ter- minals as you turn the wrench to avoid ripping the terminals from their foundations. Note the wire locations for reassembly.

Note: The brass screws are

7.To reinstall the rheostat, replace each of the brass screws. Place a

8.Reassemble the rheostat to the front of the control panel. Line up the locating tab on the rheostat with the slot on the control panel hole.

9.Reassemble the

10.Locate the flat spot on the shaft, line up the knob locking screw, push the knob onto the shaft and tighten the screw with the allen wrench.

11.Check the rheostat knob for proper rotation, minimum to maximum.

12.Replace the top cover of the con- trol box and tighten the 8 sheet metal screws with the 5/16” nut dri- ver.