OPERATION | ||

|

|

Return to Section TOC

Return to Section TOC

to Section TOC

Return to Master TOC

Return to Master TOC

to Master TOC

USING THE WIRE DRIVE ROLL

The drive roll provided with the

PROCEDURE FOR CHANGING DRIVE ROLL

Different wire sizes may require changing the drive roll. The applicable wire sizes are stamped on the drive roll. Dual groove rolls must be installed so the side with the proper wire size stamp faces out.

1.Turn POWER SWITCH to OFF.

2.Release the pressure on the idle roll by swinging the pressure arm off the idle roll arm.

3.Remove the wire from the drive system.

4.Remove the thumb screw from the drive roll.

5.Turn the drive roll over or change to another roll as required.

6.Replace the thumb screw.

7.Check that the gun liner and contact tip are prop- erly sized for wire being used.

![]() MOULDED ADAPTER

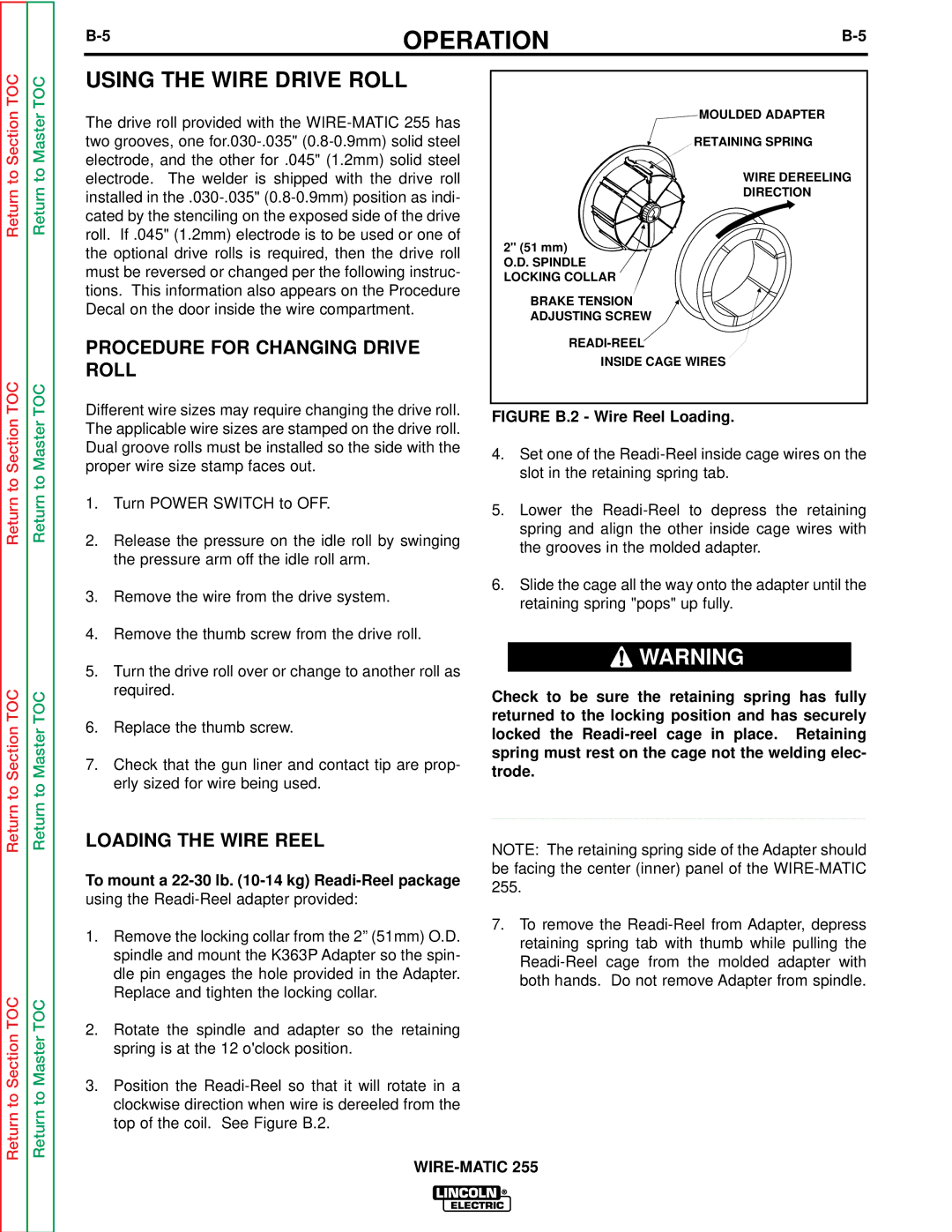

MOULDED ADAPTER

RETAINING SPRING

WIRE DEREELING

DIRECTION

2" (51 mm)

O.D. SPINDLE LOCKING COLLAR

BRAKE TENSION

ADJUSTING SCREW

INSIDE CAGE WIRES

FIGURE B.2 - Wire Reel Loading.

4.Set one of the

5.Lower the

6.Slide the cage all the way onto the adapter until the retaining spring "pops" up fully.

![]() WARNING

WARNING

Check to be sure the retaining spring has fully returned to the locking position and has securely locked the

Return

Return to Section TOC

Return

Return to Master TOC

LOADING THE WIRE REEL

To mount a

1.Remove the locking collar from the 2” (51mm) O.D. spindle and mount the K363P Adapter so the spin- dle pin engages the hole provided in the Adapter. Replace and tighten the locking collar.

2.Rotate the spindle and adapter so the retaining spring is at the 12 o'clock position.

3.Position the

____________________________________

NOTE: The retaining spring side of the Adapter should be facing the center (inner) panel of the

7.To remove the