ACCESSORIES | ||

|

|

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

MAKING A WELD WITH THE SPOOL GUN ADAPTER (K672-1) INSTALLED

![]() CAUTION

CAUTION

In either transfer switch position, closing the gun trigger will cause the electrode of both guns to be electrically "HOT." Be sure unused gun is posi- tioned so the electrode or the tip will not contact metal case or other metal common to the work. A gun holder is provided with the

____________________________________

1.The transfer switch in FEEDER position:

a.Disables spool gun trigger, wire feed, and gas output.

b.Closing the feeder gun trigger starts feeder gun welding and makes both electrodes elec- trically "HOT."

2.Transfer switch in SPOOL position:

a.Disables feeder gun wire feed and gas output. However, closing feeder gun trigger will make both electrodes electrically “HOT” and activate spool gun gas output.

b.Closing spool gun trigger starts spool gun welding and makes both electrodes electrical- ly "HOT".

3.Operation with

a.Turn the

b.Adjusting the voltage control will increase or decrease your welding Voltage.

c.Adjusting the wire speed control will increase or decrease the spool gun wire feed speed. This represents the set speed for the K469 spool gun and the maximum set speed for the K487 Spool Gun with the remote control in gun handle at maximum.

The remote control turned to minimum will give approximately 50% of the maximum set WFS.

NOTE: The

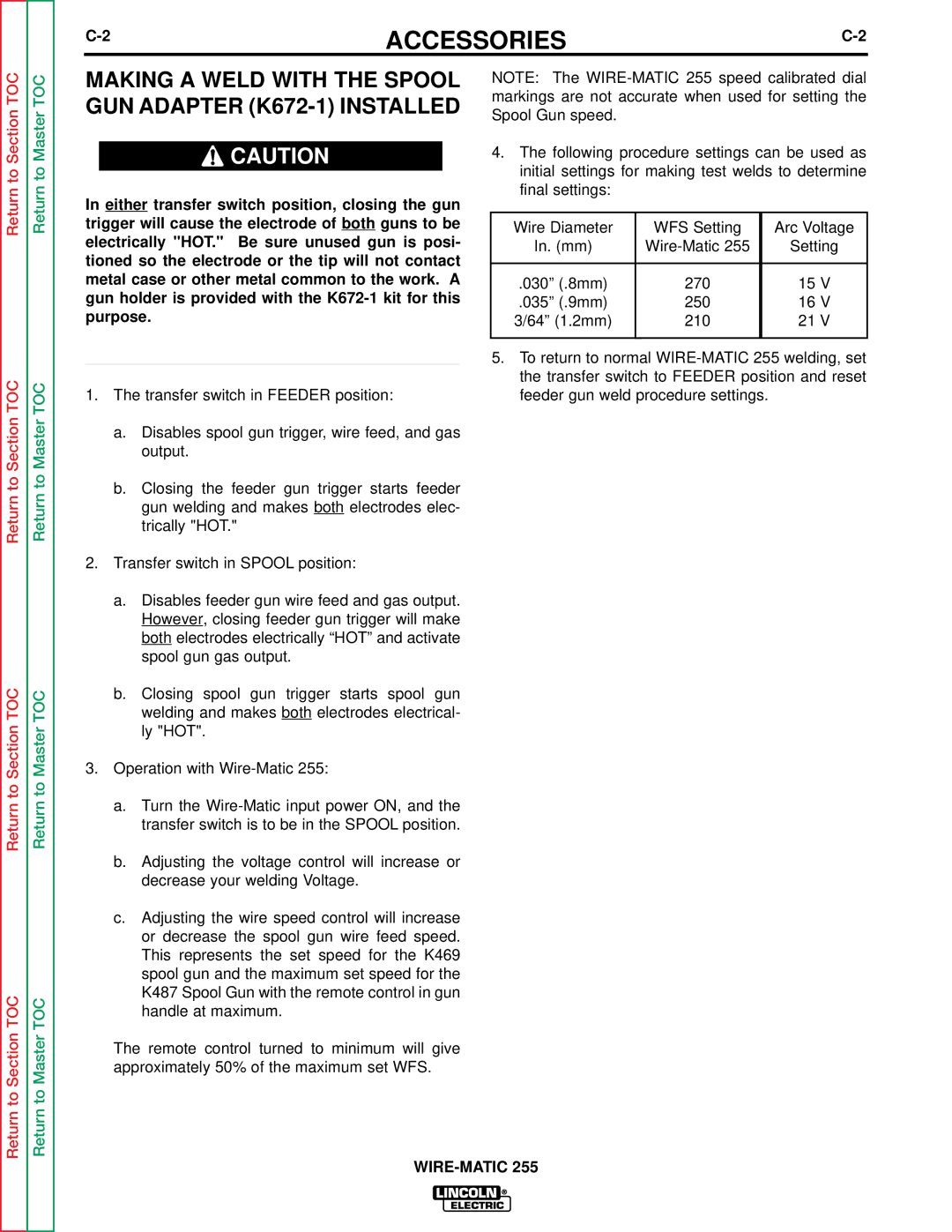

4.The following procedure settings can be used as initial settings for making test welds to determine final settings:

Wire Diameter | WFS Setting | Arc Voltage |

In. (mm) | Setting | |

|

|

|

.030” (.8mm) | 270 | 15 V |

.035” (.9mm) | 250 | 16 V |

3/64” (1.2mm) | 210 | 21 V |

|

|

|

5.To return to normal