Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR |

| |||||||

|

|

| ||||||

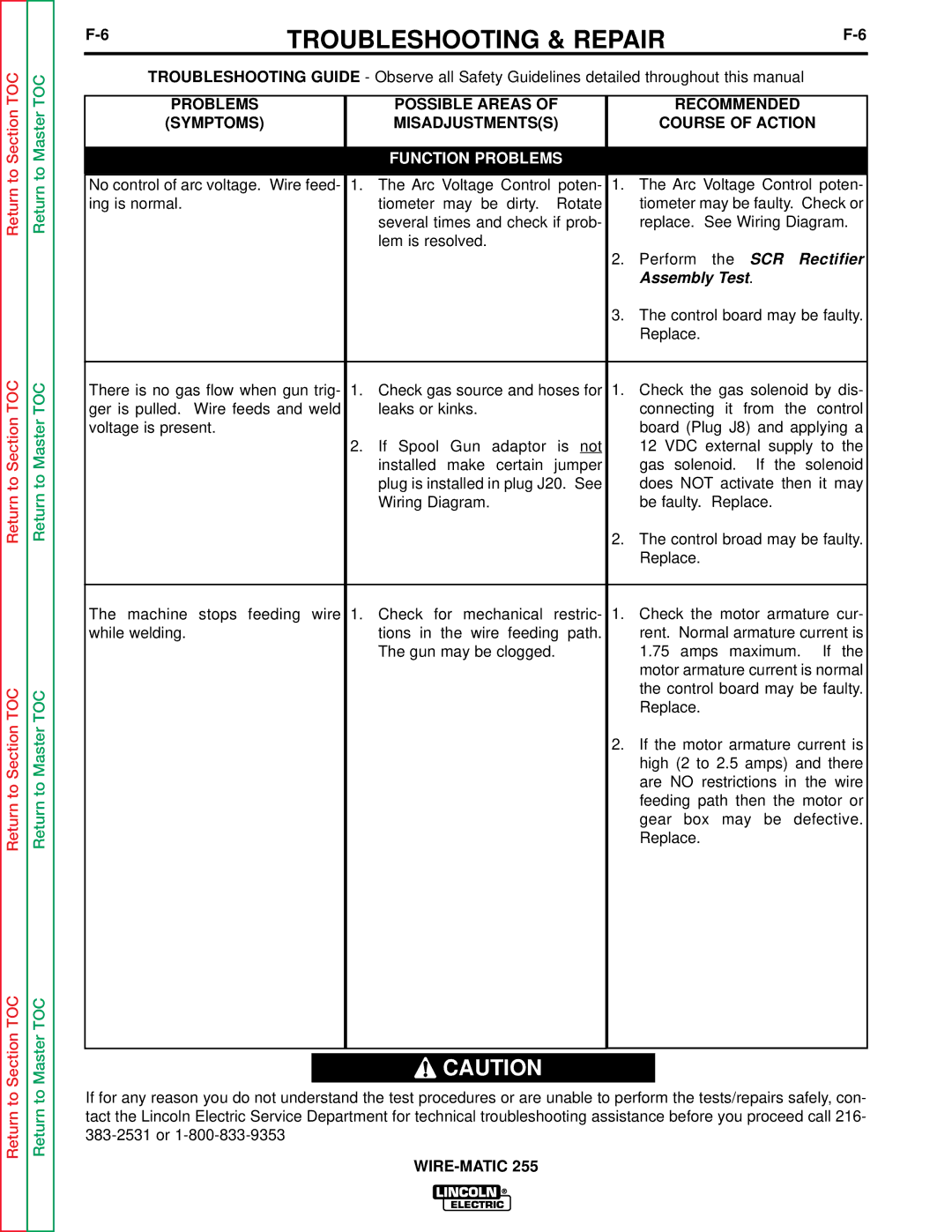

TROUBLESHOOTING GUIDE - Observe all Safety Guidelines detailed throughout this manual |

| |||||||

|

|

|

|

|

|

| ||

PROBLEMS |

|

| POSSIBLE AREAS OF |

| RECOMMENDED |

| ||

(SYMPTOMS) |

|

| MISADJUSTMENTS(S) |

| COURSE OF ACTION | |||

|

|

|

|

|

|

|

| |

|

|

| FUNCTION PROBLEMS |

|

|

|

| |

|

|

|

|

|

|

|

|

|

No control of arc voltage. Wire feed- | 1. | The Arc Voltage Control poten- | 1. | The Arc Voltage Control poten- | ||||

ing is normal. |

|

| tiometer may be dirty. | Rotate |

| tiometer may be faulty. Check or | ||

|

|

| several times and check if prob- |

| replace. See Wiring Diagram. | |||

|

|

| lem is resolved. |

|

|

|

|

|

|

|

|

|

| 2. | Perform the | SCR Rectifier | |

|

|

|

|

|

| Assembly Test. |

| |

|

|

|

|

| 3. | The control board may be faulty. | ||

|

|

|

|

|

| Replace. |

|

|

|

|

|

|

| ||||

There is no gas flow when gun trig- | 1. | Check gas source and hoses for | 1. | Check the gas solenoid by dis- | ||||

ger is pulled. Wire feeds and weld |

| leaks or kinks. |

|

| connecting it from the control | |||

voltage is present. |

|

|

|

|

| board (Plug J8) and applying a | ||

|

| 2. | If Spool Gun adaptor is not |

| 12 VDC external supply to the | |||

|

|

| installed make certain | jumper |

| gas solenoid. | If the | solenoid |

|

|

| plug is installed in plug J20. See |

| does NOT activate then it may | |||

|

|

| Wiring Diagram. |

|

| be faulty. Replace. |

| |

|

|

|

|

| 2. | The control broad may be faulty. | ||

|

|

|

|

|

| Replace. |

|

|

|

|

|

|

| ||||

The machine stops feeding wire | 1. | Check for mechanical restric- | 1. | Check the motor armature cur- | ||||

while welding. |

|

| tions in the wire feeding path. |

| rent. Normal armature current is | |||

|

|

| The gun may be clogged. |

| 1.75 amps maximum. | If the | ||

|

|

|

|

|

| motor armature current is normal | ||

|

|

|

|

|

| the control board may be faulty. | ||

|

|

|

|

|

| Replace. |

|

|

|

|

|

|

| 2. | If the motor armature current is | ||

|

|

|

|

|

| high (2 to 2.5 amps) and there | ||

|

|

|

|

|

| are NO restrictions in the wire | ||

|

|

|

|

|

| feeding path then the motor or | ||

|

|

|

|

|

| gear box may be defective. | ||

|

|

|

|

|

| Replace. |

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, con- tact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed call 216-