INSTALLATION | ||

|

|

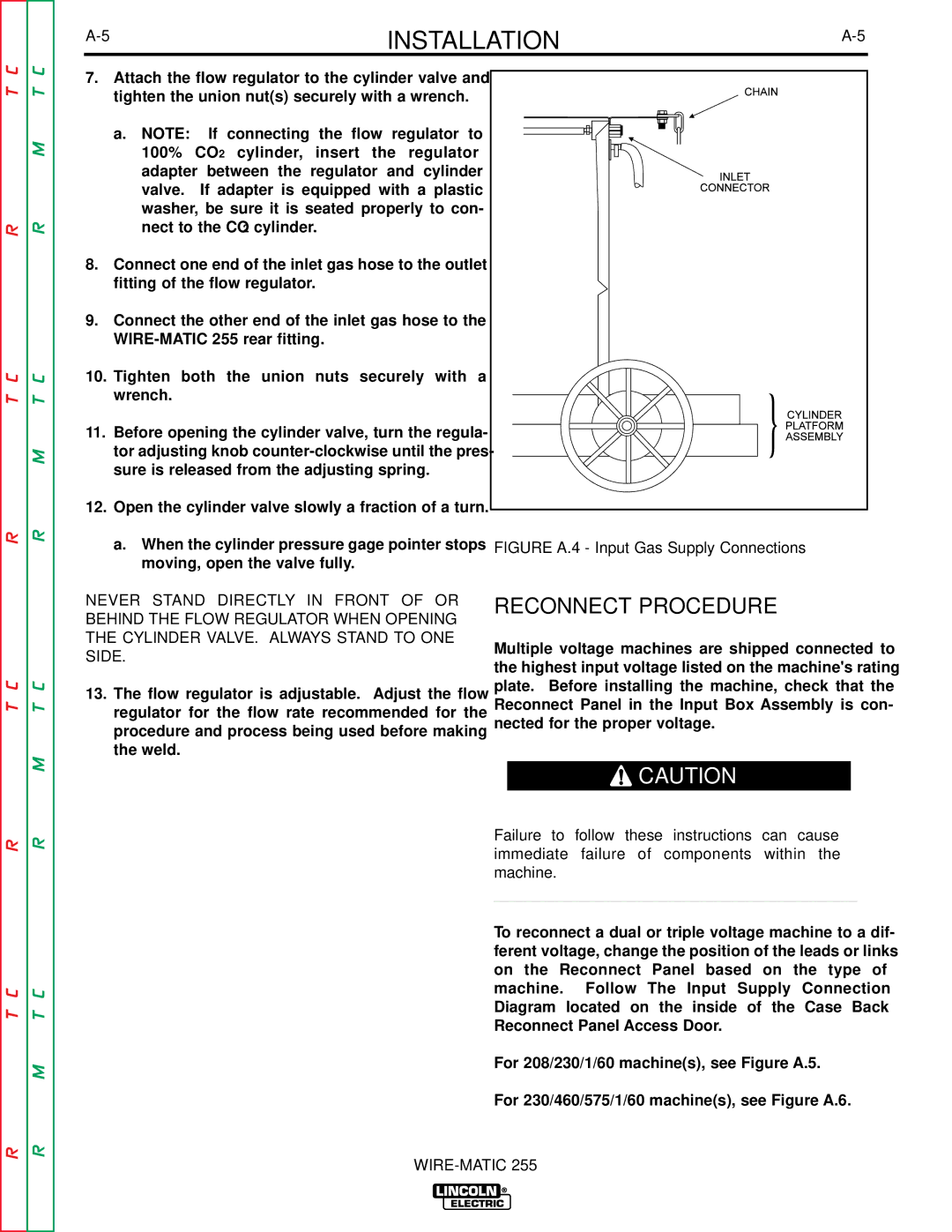

7.Attach the flow regulator to the cylinder valve and tighten the union nut(s) securely with a wrench.

a.NOTE: If connecting the flow regulator to 100% CO2 cylinder, insert the regulator adapter between the regulator and cylinder valve. If adapter is equipped with a plastic washer, be sure it is seated properly to con- nect to the CO2 cylinder.

8.Connect one end of the inlet gas hose to the outlet fitting of the flow regulator.

9.Connect the other end of the inlet gas hose to the

10.Tighten both the union nuts securely with a wrench.

11.Before opening the cylinder valve, turn the regula- tor adjusting knob

12.Open the cylinder valve slowly a fraction of a turn.

a.When the cylinder pressure gage pointer stops moving, open the valve fully.

NEVER STAND DIRECTLY IN FRONT OF OR BEHIND THE FLOW REGULATOR WHEN OPENING THE CYLINDER VALVE. ALWAYS STAND TO ONE SIDE.

13.The flow regulator is adjustable. Adjust the flow regulator for the flow rate recommended for the procedure and process being used before making the weld.

FIGURE A.4 - Input Gas Supply Connections

RECONNECT PROCEDURE

Multiple voltage machines are shipped connected to the highest input voltage listed on the machine's rating plate. Before installing the machine, check that the Reconnect Panel in the Input Box Assembly is con- nected for the proper voltage.

![]() CAUTION

CAUTION

Failure to follow these instructions can cause immediate failure of components within the machine.

___________________________________

To reconnect a dual or triple voltage machine to a dif- ferent voltage, change the position of the leads or links on the Reconnect Panel based on the type of machine. Follow The Input Supply Connection Diagram located on the inside of the Case Back Reconnect Panel Access Door.

Return to Master

For 208/230/1/60 machine(s), see Figure A.5.

For 230/460/575/1/60 machine(s), see Figure A.6.