5. IMPROVING EFFICIENCY OF PIPING WORK

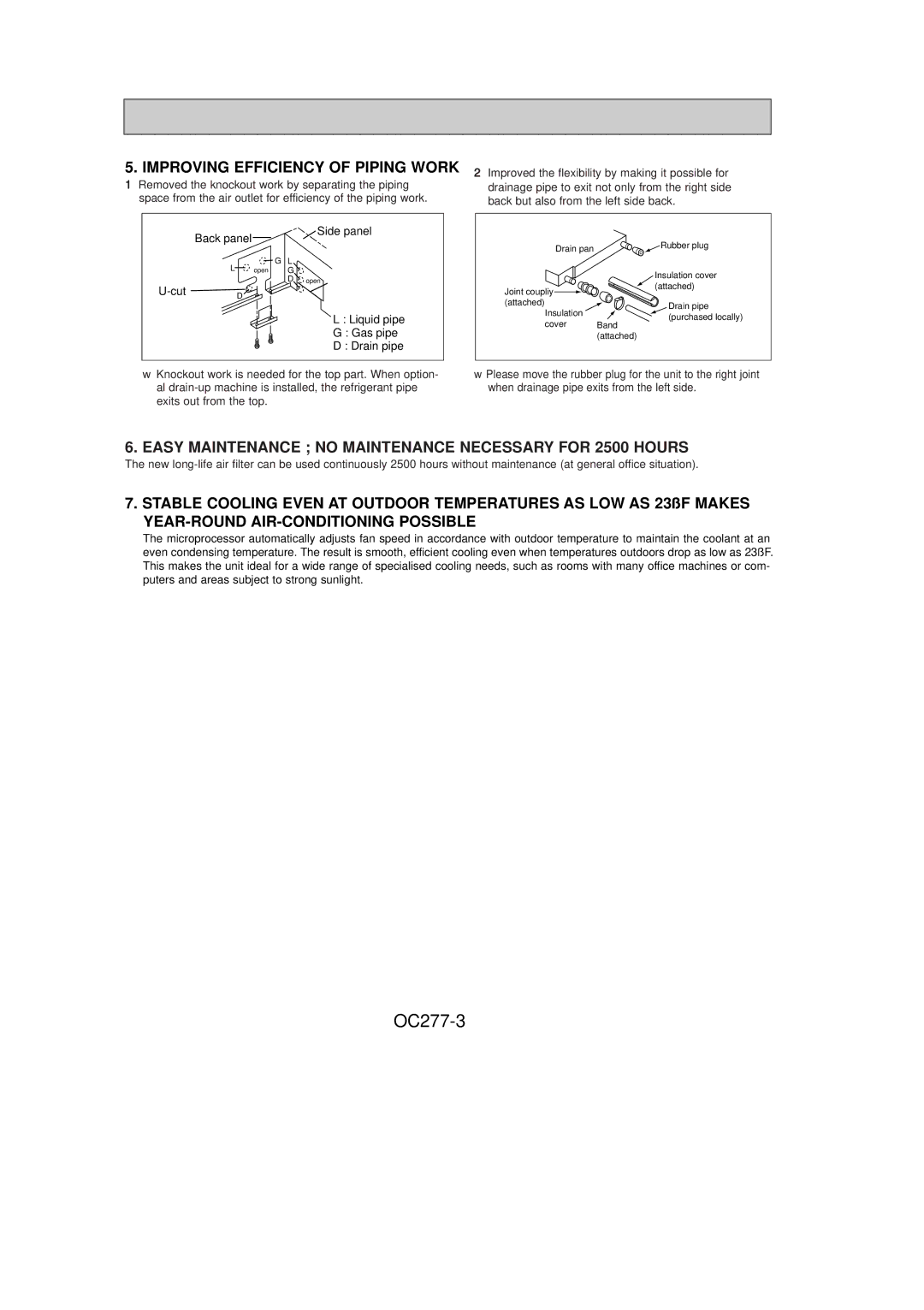

1Removed the knockout work by separating the piping space from the air outlet for efficiency of the piping work.

2Improved the flexibility by making it possible for drainage pipe to exit not only from the right side back but also from the left side back.

Back panel

Side panel

G L

L open G

D open

U-cut D

L : Liquid pipe

G : Gas pipe

Drain pan | Rubber plug | |

| ||

| Insulation cover | |

Joint coupliy | (attached) | |

| ||

(attached) | Drain pipe | |

Insulation | ||

(purchased locally) | ||

cover | ||

Band | ||

| (attached) |

D : Drain pipe

wKnockout work is needed for the top part. When option- al

wPlease move the rubber plug for the unit to the right joint when drainage pipe exits from the left side.

6. EASY MAINTENANCE ; NO MAINTENANCE NECESSARY FOR 2500 HOURS

The new

7. STABLE COOLING EVEN AT OUTDOOR TEMPERATURES AS LOW AS 23˚F MAKES

The microprocessor automatically adjusts fan speed in accordance with outdoor temperature to maintain the coolant at an even condensing temperature. The result is smooth, efficient cooling even when temperatures outdoors drop as low as 23˚F. This makes the unit ideal for a wide range of specialised cooling needs, such as rooms with many office machines or com- puters and areas subject to strong sunlight.