as metal shavings or grinding dust, can damage the

PANEL LAYOUT

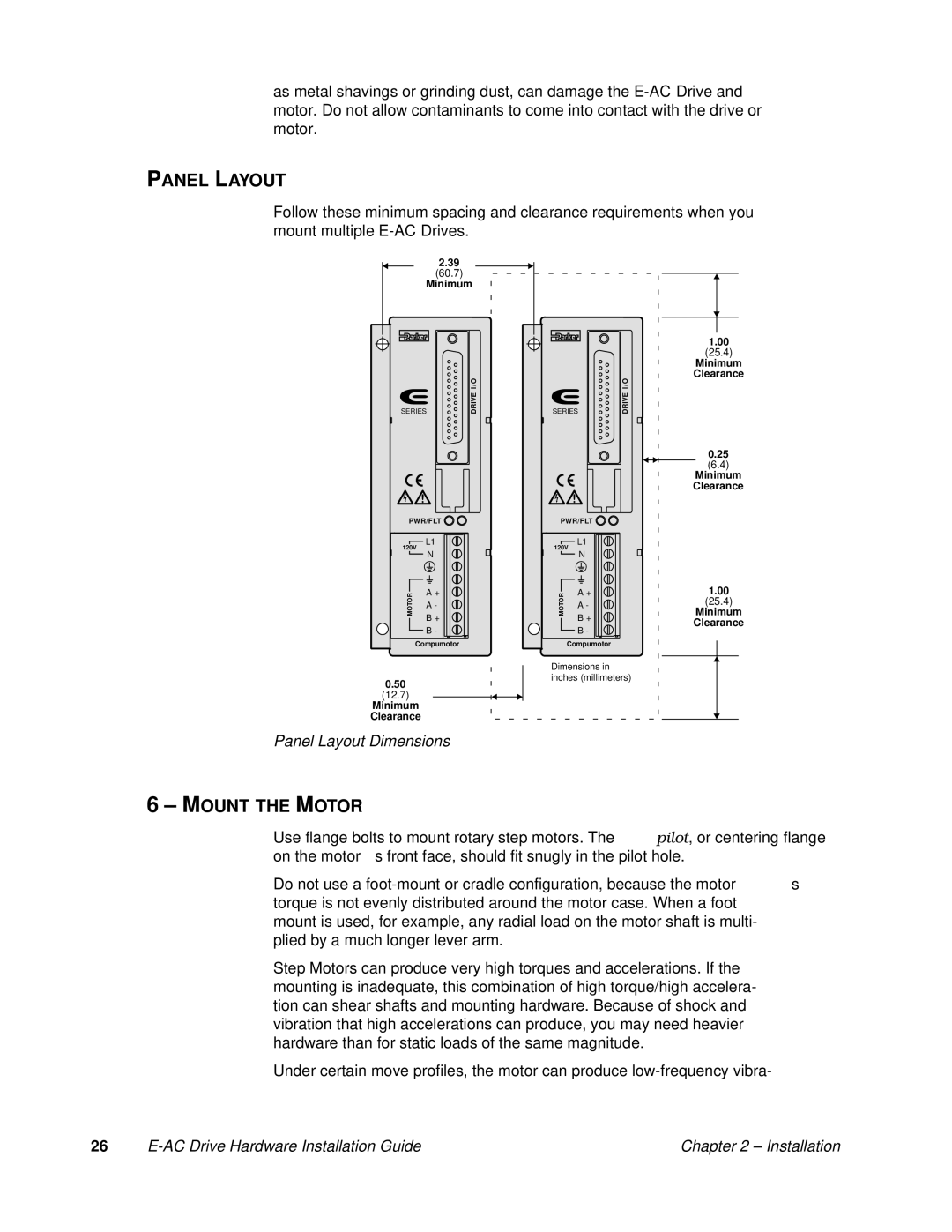

Follow these minimum spacing and clearance requirements when you mount multiple

2.39

(60.7)

Minimum

| I/O |

SERIES | DRIVE |

PWR/FLT

L1

120V

N

|

| A + | |

MOTOR | |||

A - | |||

|

| ||

|

| B + | |

|

| B - | |

|

| ||

Compumotor

0.50

(12.7)

Minimum

Clearance

Panel Layout Dimensions

1.00

(25.4)

Minimum

Clearance

| I/O |

SERIES | DRIVE |

0.25

(6.4)

Minimum

Clearance

PWR/FLT

L1

120V

N

MOTOR | A + | 1.00 |

| Minimum | |

| A - | (25.4) |

|

| |

| B + | Clearance |

| B - | |

|

| |

| Compumotor |

|

Dimensions in |

| |

inches (millimeters) |

| |

6–MOUNT THE MOTOR

Use flange bolts to mount rotary step motors. The pilot, or centering flange on the motor’s front face, should fit snugly in the pilot hole.

Do not use a

Step Motors can produce very high torques and accelerations. If the mounting is inadequate, this combination of high torque/high accelera- tion can shear shafts and mounting hardware. Because of shock and vibration that high accelerations can produce, you may need heavier hardware than for static loads of the same magnitude.

Under certain move profiles, the motor can produce

26 |

| Chapter 2 – Installation |