CONNECTING THE MOTOR: PARALLEL WIRING

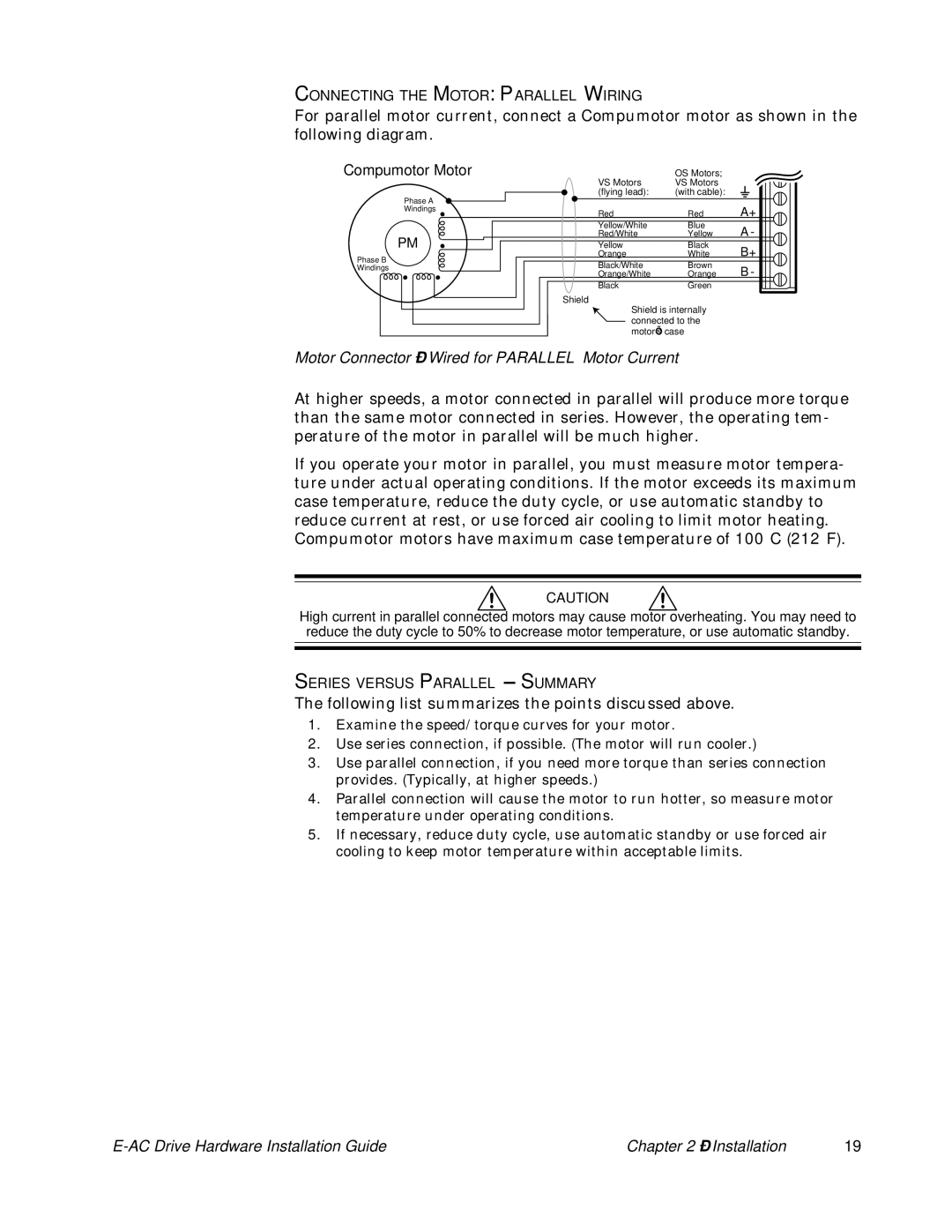

For parallel motor current, connect a Compumotor motor as shown in the following diagram.

Compumotor Motor

VS Motors | OS Motors; |

VS Motors | |

(flying lead): | (with cable): |

Phase A |

|

| A+ |

Windings | Red | Red | |

| |||

| Yellow/White | Blue | A - |

PM | Red/White | Yellow | |

Yellow | Black | B+ | |

Phase B | Orange | White | |

Black/White | Brown |

| |

Windings | B - | ||

| Orange/White | Orange | |

| Black | Green |

|

Shield

Shield is internally connected to the motor’s case

Motor Connector – Wired for PARALLEL Motor Current

At higher speeds, a motor connected in parallel will produce more torque than the same motor connected in series. However, the operating tem- perature of the motor in parallel will be much higher.

If you operate your motor in parallel, you must measure motor tempera- ture under actual operating conditions. If the motor exceeds its maximum case temperature, reduce the duty cycle, or use automatic standby to reduce current at rest, or use forced air cooling to limit motor heating. Compumotor motors have maximum case temperature of 100° C (212° F).

CAUTION

High current in parallel connected motors may cause motor overheating. You may need to reduce the duty cycle to 50% to decrease motor temperature, or use automatic standby.

SERIES VERSUS PARALLEL –SUMMARY

The following list summarizes the points discussed above.

1.Examine the speed/torque curves for your motor.

2.Use series connection, if possible. (The motor will run cooler.)

3.Use parallel connection, if you need more torque than series connection provides. (Typically, at higher speeds.)

4.Parallel connection will cause the motor to run hotter, so measure motor temperature under operating conditions.

5.If necessary, reduce duty cycle, use automatic standby or use forced air cooling to keep motor temperature within acceptable limits.

| Chapter 2 – Installation | 19 |