DC Inverter MULTI-SYSTEM AIR Conditioner

RoHS

For safe installation and trouble-free operation, you must

Please Read Before Starting

Table of Contents

Installation Instructions Appendix a

Applicable Indoor Units

Outdoor Unit SAP-CMRV1426EH, SAP-CMRV1926EH, SAP-CMRV1936EH

C D.B. When combined with SAP-KRV186EH or SAP-KRV246EH

Indoor Unit SAP-KRV96EHDSA, SAP-KRV126EHDS

Unit Specifications

Outdoor Unit

Indoor Unit

SAP-KMRV96EH ⋅

SAP-CMRV1926EH

SAP-KMRV96EH ⋅ 1 + SAP-KRV186EH ⋅

SAP-CMRV1936EH

SAP-CMRV2446EH

SAP-CMRV3146EH

Outdoor Unit

Major Component Specifications

Outdoor Unit SAP-CMRV1426EH

Outdoor Unit SAP-CMRV1926EH

Outdoor Unit SAP-CMRV1936EH

Outdoor Unit SAP-CMRV2446EH

Outdoor Unit SAP-CMRV3146EH

Other Component Specifications

Temperature C

Dimensional Data

ID23

Unit mm 852-0-0010-13400-0

Unit mm 852-0-0010-10900-0

Unit mm 852-0-0010-11000-0

Unit mm 852-0-0010-11100-0

Insulation of Refrigerant Tubing

Refrigerant Flow Diagram

Outdoor Unit SAP-CMRV1426EH Indoor unit Outdoor unit

Outdoor Unit SAP-CMRV1926EH Indoor unit Outdoor unit

Outdoor Unit SAP-CMRV1936EH Indoor unit Outdoor unit

Outdoor Unit SAP-CMRV2446EH Indoor unit Outdoor unit

Outdoor Unit SAP-CMRV3146EH Indoor unit Outdoor unit

Temperature Charts

Temperature Charts SAP-CMRV1426EH

Operating current performance chart

Indoor discharge air performance chart

Low pressure performance chart

Outdoor Unit SAP-CMRV1426EH Indoor Unit SAP-KMRV96EH ⋅

Outdoor Unit SAP-CMRV1426EHIndoor Unit

Outdoor Unit SAP-CMRV1426EH Indoor Unit SAP-KRV96EHDSA ⋅

SAP-KRV126EHDS ⋅

Temperature Charts SAP-CMRV1926EH

Outdoor Unit SAP-CMRV1926EH Indoor Unit SAP-KMRV76EH ⋅

24C Outdoor air temperature C Airtemp Indoor 20C

Outdoor Unit SAP-CMRV1926EHIndoor Unit

30C

Outdoor Unit SAP-CMRV1926EHIndoor Unit SAP-KRV186EH ⋅

SAP-KRV96EHDSA ⋅

Air Indoor Airtemp Discharge 24C Outdoor air temperature C

Temperature Charts SAP-CMRV1936EH

Outdoor Unit SAP-CMRV1936EHIndoor Unit

Indoor 27C

Tube service valve MPaG kgf/cm 2G 40.8 35.7 Atwide

Outdoor Unit SAP-CMRV1936EH Indoor Unit SAP-KRV186EH ⋅

12.2 30.6 Pressure 11.2 25.5

SAP-KRV126EHDS ⋅

Temperature Charts SAP-CMRV2446EH

Outdoor Unit SAP-CMRV2446EHIndoor Unit

SAP-KMRV96EH ⋅

SAP-KMRV126EH ⋅

Outdoor Unit SAP-CMRV2446EH Indoor Unit SAP-KRV186EH ⋅

Outdoor Unit SAP-CMRV2446EH Indoor Unit SAP-KRV246EH ⋅

Indoor Airtemp 17C Outdoor air temperature C

SAP-KRV126EHDS ⋅

Temperature Charts SAP-CMRV3146EH

Outdoor Unit SAP-CMRV3146EHIndoor Unit

Current a Operating Outdoor air temperature C

Temp Air Indoor 20C

Outdoor Unit SAP-CMRV3146EHIndoor Unit SAP-KRV186EH ⋅

Outdoor Unit SAP-CMRV3146EHIndoor Unit SAP-KRV246EH ⋅

SAP-KRV96EHDSA ⋅

SAP-KRV126EHDS ⋅

Electric Wiring Diagrams

8FA2-5257-56900-2

Unit GND

Supply Unit Inddor to

BRN GRY ORG YEL RED

Terminal Plate Supply Power GND Unit Inddor to

Functions

Explanation of Functions

Temperature of releasing

Cool

Fluctuation fan

DRY

Clean defrost

Protective Functions

Defrost Detection and Release

Non-stop defrosting

Current Control

Description of function

Automatic frequency control

Current control

Compressor Temperature Control

Reset conditions

Low Start Current

Control at Heat Start-up

Troubleshooting

Precautions before Performing Inspection or Repair

Location of the Error Monitor Lamps

Trouble Diagnosis by Error Monitor Lamps

Display of the Error Monitor Lamps

Work procedure Check items unit operation

Checking the Outdoor System

Checking the outdoor unit

Checking the defrost operation

Problems of Each Part and Inspection Points

Trouble Diagnosis of Each Part

Inspection Points for Each Part

Breaker

Branch tubing temperature sensor

Refrigerant gas pressure

Diagnostic procedure

Diagnostic results

Remedy for symptom 3 to

Trouble Diagnosis of Fan Motor

Characteristics of New Refrigerant R410A

Checklist before Servicing

What is New Refrigerant R410A?

Characteristics

Tubing precautions

No addition of compressor oil for R410A

No use of refrigerant other than R410A

If refrigerant R410A is exposed to fire

Tubing Installation Procedures

Tools Specifically for R410A

Procedure for Replacing Compressor

Case of Compressor Malfunction

Never charge a large amount

Unit. This may cause

Damage to the compressor

Example

Welding leaking points

Case Refrigerant is Leaking

Recharging

When Tubes are Extended

Charging Additional Refrigerant

Retro-Fitting Existing Systems

Use of Existing Units

Appendix a Installation Instructions SAP-CMRV1426EH

Contents

For Outdoor Unit

For safe installation and trouble-free operation, you must

…In a Ceiling or Wall

…In a Room

…In Moist or Uneven Locations

Tools Required for Installation not supplied

Accessories Supplied with Unit Table

General

Optional Copper Tubing Kit

Installation Site Selection

Additional Materials Required for Installation

Connecting indoor unit for SAP-CMRV1426

Connecting Indoor Units

Unit mm

Where snow will not blow into it

Install in a location where at least two sides are

Space is ensured for maintenance to be carried out

Decreased service life. c

Outer Dimensions of Outdoor Unit

Never install only a single indoor unit

Flaring Procedure with a Flare Tool

Installation Process

Use of the Flaring Method

Tubing Connections

Tube Dia Tightening Torque

Tubing and electric wiring

Finishing the Installation

Be sure to match refrigerant

Units

Air Purging

Air Purging with a Vacuum Pump for Test Run

Be sure to completely insert

Hex wrench before

If a CFC gas detector is used

Use a special detector for HFC

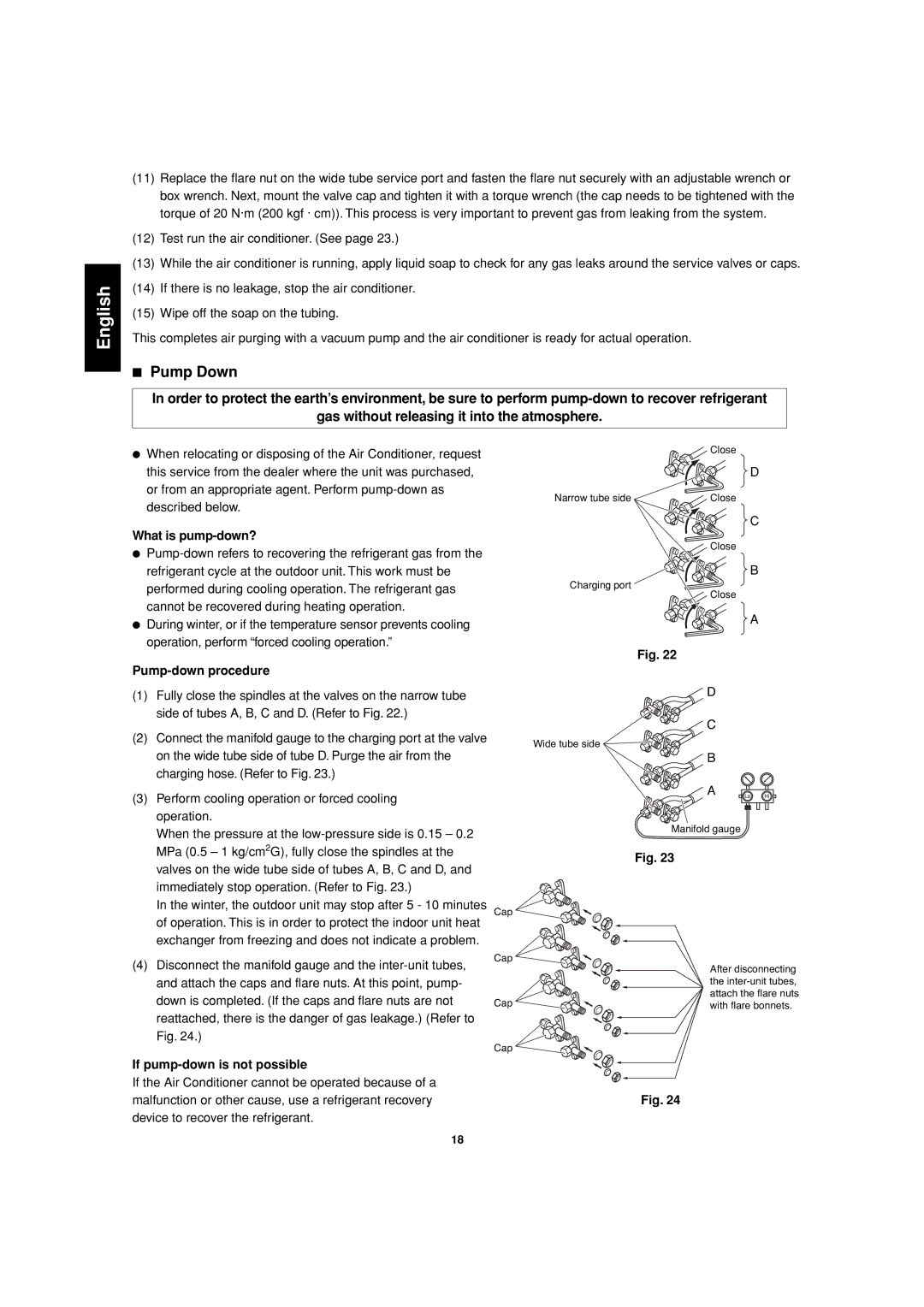

What is pump-down?

Pump-down procedure

Pump Down

If pump-down is not possible

General Precautions on Wiring

Wiring Instructions

Recommended Wire Length and Diameter

Outdoor Unit

Fore, be sure all wiring is

How to connect wiring to the terminal For Indoor Unit

For Outdoor Unit For solid core wiring or F-cable

For stranded wiring

Wiring Instructions for the Outdoor Unit

Be sure to perform grounding

Test Run

Checking tubing and wiring

Performing a test run

Connecting a Home Automation Device

Installation Check Sheet

Electric Wiring Diagram

Indoor Unit SAP-KMRV74/94/124EH

SAP-KMRV76/96/126EH

Controller

II-852-6-4190-442-00-2

Deutsch Italiano Português EÏÏËÓÈο

Install the outdoor unit on a raised platform that is

Higher than drifting snow. Provide snow vents

C D

Within a total tubing length L1+L2, L1+L2+L3

H1, H2, H3, H4 above or below the outdoor unit

L1+L2+L3+L4 from the outdoor unit as detailed

Connecting indoor unit for SAP-CMRV1926

H1, H2, H3, H4

Connecting indoor unit for SAP-CMRV1936

Connecting indoor unit for SAP-CMRV2446

Outdoor unit Indoor unit

Connecting indoor unit for SAP-CMRV3146

Ø12.70 Ø6.35 Ø15.88

Install in a location where at least two sides are unob

Structed, so that the flow of air at the intake port or

Exhaust port is not blocked, and so that sufficient

Block, 15 ⋅ 40 cm beams or equal, a minimum

SAP-CMRV1926

SAP-CMRV1936

SAP-CMRV2446

SAP-CMRV3146

Indoor unit D Indoor unit C Indoor unit B

Installation Process

Service valve on narrow tube side

Torque wrench Spanner Indoor unit Outdoor unit

Before using the vacuum pump

Moisture in the air may freeze and block capillary

Tubing

Water may lead to corrosion of parts Refrigerant system

Attempting to turn the valve

Close

Fuse

Indoor units with SAP-CMRV2446, CMRV3146

Insulation Stranded wire Ring

Wiring. The units will not function if the wiring

Indoor unit C

Indoor unit D

Be sure to apply the provided labels to both

Access panel C

Diagrama de cableado eléctrico

Diagramme de câblage électrique

Diagramma dei circuiti elettrici

Diagrama da fiação elétrica

SAP-KRV184/244EH SAP-KMRV76/96/126EH

8FA-2-5257-68200-0

∂͈ÙÂÚÈ΋ ÌÔÓ¿‰·

8FA-2-5257-57100-0

English Español Français Deutsch

Appendix C Unit Combination Tables

List of Combination Table

Combinations of Connectable Indoor Units

Conditions

SAP-CMRV1426EH

SAP-CMRV1926EH

SAP-CMRV1926EHV1924EH

SAP-CMRV1936EH

SAP-CMRV1936EHRV1934EH

SAP-CMRV2446EH

SAP-CMRV24446EH

SAP-KRV96EHDS SAP-KRV126EHDS

SAP-CMRV3146EH

SAP-CMRV3146EH

Combinations of operatable indoor units

SAP-KRV96EHDS SAP-KRV126EHDS

Osaka, Japan Jan