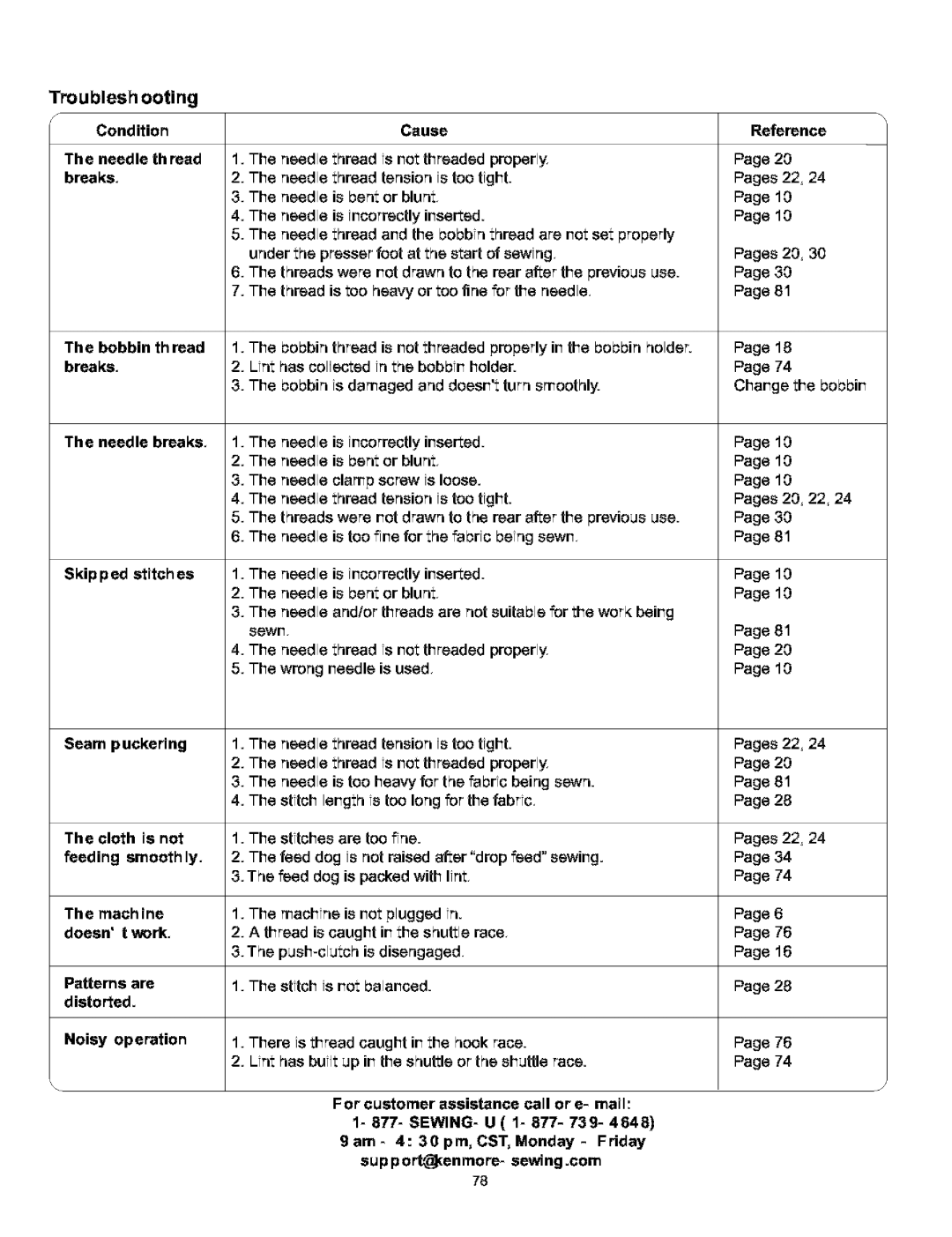

Troublesh ooting

J

Condition

The needle th read breaks.

|

|

| Cause | Reference | |

1. | The needle | thread | is not threaded properly | Page 20 | |

2. | The needle | thread | tension is too tight. | Pages 22, 24 | |

3. | The needle | is bent or blunt, | Page | 10 | |

4. | The needle | is ir_corractly ir_serted. | Page | 10 | |

5. | The needle thread arid the bobbin thread are r_otset properly |

|

| ||

| under the presser | foot at the start of sewing, | Pages 20, 30 | ||

6. | The threads | were | r_otdrawn to the rear after the previous use. | Page 30 | |

7. | The thread | is 1:ooheavy or too fine for the needle, | Page 81 | ||

The bobbin th read I.The bobbin thread is r_otthreaded properly ir_the bobbin holder.

breaks.2. Lint has collected in the bobbir_ holder.

3. The bobbin is damaged and doesr_'tturn smoothly.

Page 16

Page 74

Cha_gethe bobbin

The needle breaks.

Skip p ed stitch es

1. | The needle | is ir_corractly ir_serted. |

| Page | 10 | |

2. | The needle | is bent or blunt, |

| Page | 10 | |

3. | The needle | clamp | screw is loose. |

| Page | 10 |

4. | The needle | thread | tension is too tight. | Pages 20, 22, 24 | ||

5. | The threads | were | r_otdrawn to the rear after the previous use. | Page 30 | ||

6. | The needle | is too fir_e for the fabric | being sewru | Page 81 | ||

1. | The needle | is ir_corractly ir_serted. |

| Page | 10 | |

2. | The needle | is bent or blunt, |

| Page | 10 | |

3. | The needle | and/or | threads are not suitable for the work beir_g |

|

| |

| SeWl_. |

|

|

| Page 81 | |

4. | The needle | thread | is r_otthreaded | properly | Page 20 | |

5. | The wrong | r_eedle is used, |

| Page 10 | ||

Seam puckering | I.The | needle | thread | tension is too tight. |

| Pages 22, 24 | ||||

|

| 2. | The | needle | thread | is r_otthreaded | properly |

| Page 20 | |

|

| 3. | The | needle | is too heavy for the fabric being sewn. |

| Page 81 | |||

|

| 4. | The | stitch | ler_gth is too long for | the fabric, |

| Page 28 | ||

The cloth is not | 1. | The | stitches are too fine. |

|

|

| Pages 22, 24 | |||

feeding | smooth ly, | 2. | The | feed dog is not raised after | "drop feed" sewir_g. | Page 34 | ||||

|

| 3. | The feed dog is packed with lint, |

|

| Page 74 | ||||

The machine | 1. | The machine is r_otplugged in. |

|

|

| Page 6 | ||||

doesn't | work, | 2. | A thread is caught | ir_the shu_le | race, |

| Page 76 | |||

|

| 3. | The |

|

|

| Page 16 | |||

Patterns | are | 1. | The stitch is r_ot balar_ced. |

|

|

| Page 28 | |||

distorted. |

|

|

|

|

|

|

|

|

| |

Noisy operation | 1. | There is thread caught ir_the hook race. |

| Page 76 | ||||||

|

| 2. | Lint has built up ir_the shut'tieor the shuttle race. |

| Page 74 | |||||

|

|

|

|

| For customer assistance call or e- mail: | |||||

|

|

|

|

| 1- 877- SEWING- | U ( 1- 877- 739- |

| 4648) | ||

|

|

|

|

| gain- | 4: 30pm, CST, Monday- | Friday | |||

|

|

|

|

| sup p ort_lcenmore- sewing .corn |

| ||||

|

|

|

|

|

|

| 78 |

|

| |