Synchronization (Option) | The setup order for the different synchronization options |

|

|

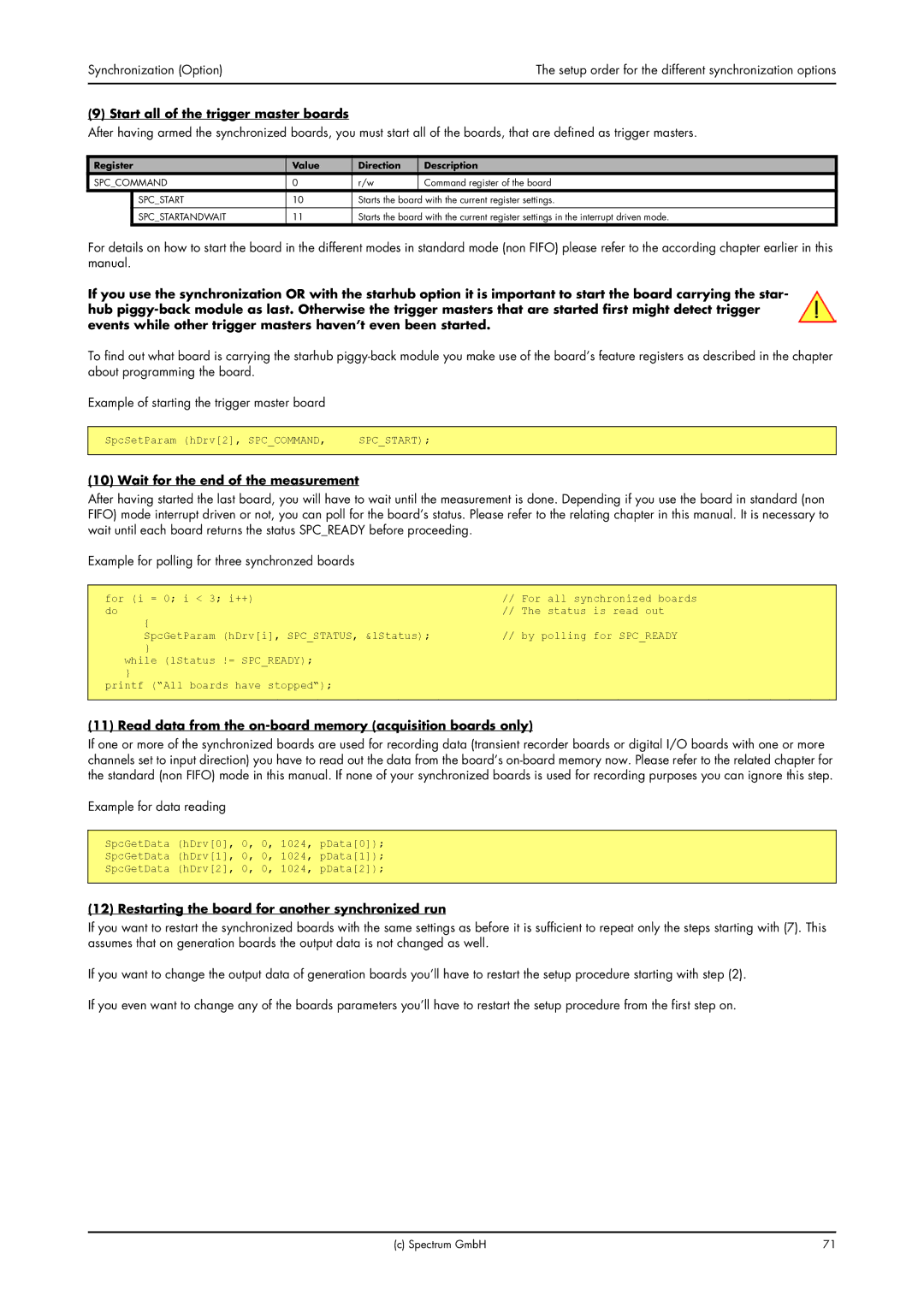

(9) Start all of the trigger master boards

After having armed the synchronized boards, you must start all of the boards, that are defined as trigger masters.

Register | Value | Direction | Description | |

SPC_COMMAND | 0 | r/w | Command register of the board | |

| SPC_START | 10 | Starts the board with the current register settings. | |

|

|

|

| |

| SPC_STARTANDWAIT | 11 | Starts the board with the current register settings in the interrupt driven mode. | |

For details on how to start the board in the different modes in standard mode (non FIFO) please refer to the according chapter earlier in this manual.

If you use the synchronization OR with the starhub option it is important to start the board carrying the star- hub

To find out what board is carrying the starhub

Example of starting the trigger master board

SpcSetParam (hDrv[2], SPC_COMMAND, | SPC_START); |

|

|

(10) Wait for the end of the measurement

After having started the last board, you will have to wait until the measurement is done. Depending if you use the board in standard (non FIFO) mode interrupt driven or not, you can poll for the board’s status. Please refer to the relating chapter in this manual. It is necessary to wait until each board returns the status SPC_READY before proceeding.

Example for polling for three synchronzed boards

for (i = 0; i < 3; i++) | // For all synchronized boards |

do | // The status is read out |

{ | // by polling for SPC_READY |

SpcGetParam (hDrv[i], SPC_STATUS, &lStatus); | |

} |

|

while (lStatus != SPC_READY); |

|

} |

|

printf (“All boards have stopped“); |

|

(11) Read data from the on-board memory (acquisition boards only)

If one or more of the synchronized boards are used for recording data (transient recorder boards or digital I/O boards with one or more channels set to input direction) you have to read out the data from the board’s

Example for data reading

SpcGetData (hDrv[0], 0, 0, 1024, pData[0]);

SpcGetData (hDrv[1], 0, 0, 1024, pData[1]);

SpcGetData (hDrv[2], 0, 0, 1024, pData[2]);

(12) Restarting the board for another synchronized run

If you want to restart the synchronized boards with the same settings as before it is sufficient to repeat only the steps starting with (7). This assumes that on generation boards the output data is not changed as well.

If you want to change the output data of generation boards you’ll have to restart the setup procedure starting with step (2).

If you even want to change any of the boards parameters you’ll have to restart the setup procedure from the first step on.

(c) Spectrum GmbH | 71 |