The setup order for the different synchronization options | Synchronization (Option) |

|

|

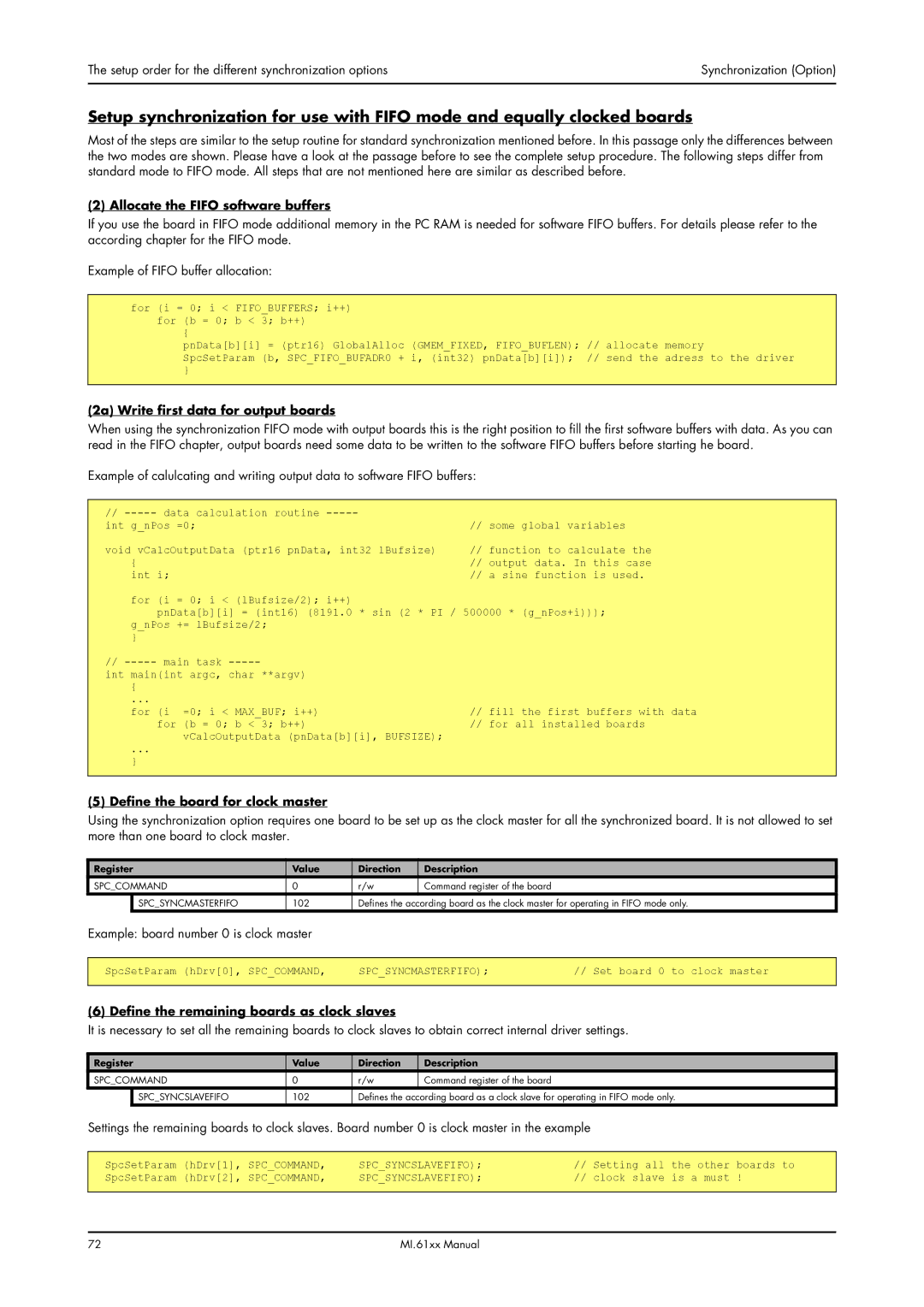

Setup synchronization for use with FIFO mode and equally clocked boards

Most of the steps are similar to the setup routine for standard synchronization mentioned before. In this passage only the differences between the two modes are shown. Please have a look at the passage before to see the complete setup procedure. The following steps differ from standard mode to FIFO mode. All steps that are not mentioned here are similar as described before.

(2) Allocate the FIFO software buffers

If you use the board in FIFO mode additional memory in the PC RAM is needed for software FIFO buffers. For details please refer to the according chapter for the FIFO mode.

Example of FIFO buffer allocation:

for (i = 0; i < FIFO_BUFFERS; i++) for (b = 0; b < 3; b++)

{

pnData[b][i] = (ptr16) GlobalAlloc (GMEM_FIXED, FIFO_BUFLEN); // allocate memory

SpcSetParam (b, SPC_FIFO_BUFADR0 + i, (int32) pnData[b][i]); // send the adress to the driver

}

(2a) Write first data for output boards

When using the synchronization FIFO mode with output boards this is the right position to fill the first software buffers with data. As you can read in the FIFO chapter, output boards need some data to be written to the software FIFO buffers before starting he board.

Example of calulcating and writing output data to software FIFO buffers:

// | // some global | variables | ||

int g_nPos =0; | ||||

void vCalcOutputData (ptr16 pnData, int32 lBufsize) | // function to | calculate the | ||

{ | // output | data. In | this case | |

int i; | // a sine | function | is used. | |

for (i = 0; i < (lBufsize/2); i++)

pnData[b][i] = (int16) (8191.0 * sin (2 * PI / 500000 * (g_nPos+i))); g_nPos += lBufsize/2;

}

// |

|

int main(int argc, char **argv) |

|

{ |

|

... | // fill the first buffers with data |

for (i =0; i < MAX_BUF; i++) | |

for (b = 0; b < 3; b++) | // for all installed boards |

vCalcOutputData (pnData[b][i], BUFSIZE); |

|

... |

|

} |

|

(5) Define the board for clock master

Using the synchronization option requires one board to be set up as the clock master for all the synchronized board. It is not allowed to set more than one board to clock master.

Register | Value | Direction | Description |

| |

SPC_COMMAND | 0 | r/w | Command register of the board |

| |

| SPC_SYNCMASTERFIFO | 102 | Defines the according board as the clock master for operating in FIFO mode only. | ||

Example: board number 0 is clock master |

|

|

| ||

|

|

|

|

|

|

SpcSetParam (hDrv[0], SPC_COMMAND, | SPC_SYNCMASTERFIFO); | // Set board 0 to clock master | |||

|

|

|

|

|

|

(6) Define the remaining boards as clock slaves

It is necessary to set all the remaining boards to clock slaves to obtain correct internal driver settings.

Register | Value | Direction | Description |

| |

SPC_COMMAND | 0 | r/w | Command register of the board |

| |

| SPC_SYNCSLAVEFIFO | 102 | Defines the according board as a clock slave for operating in FIFO mode only. | ||

Settings the remaining boards to clock slaves. Board number 0 is clock master in the example | |||||

|

|

|

|

|

|

SpcSetParam (hDrv[1], SPC_COMMAND, | SPC_SYNCSLAVEFIFO); | // Setting all the other boards to | |||

SpcSetParam (hDrv[2], SPC_COMMAND, | SPC_SYNCSLAVEFIFO); | // clock slave is a must ! | |||

72 | MI.61xx Manual |