SSPET5

3.1. General

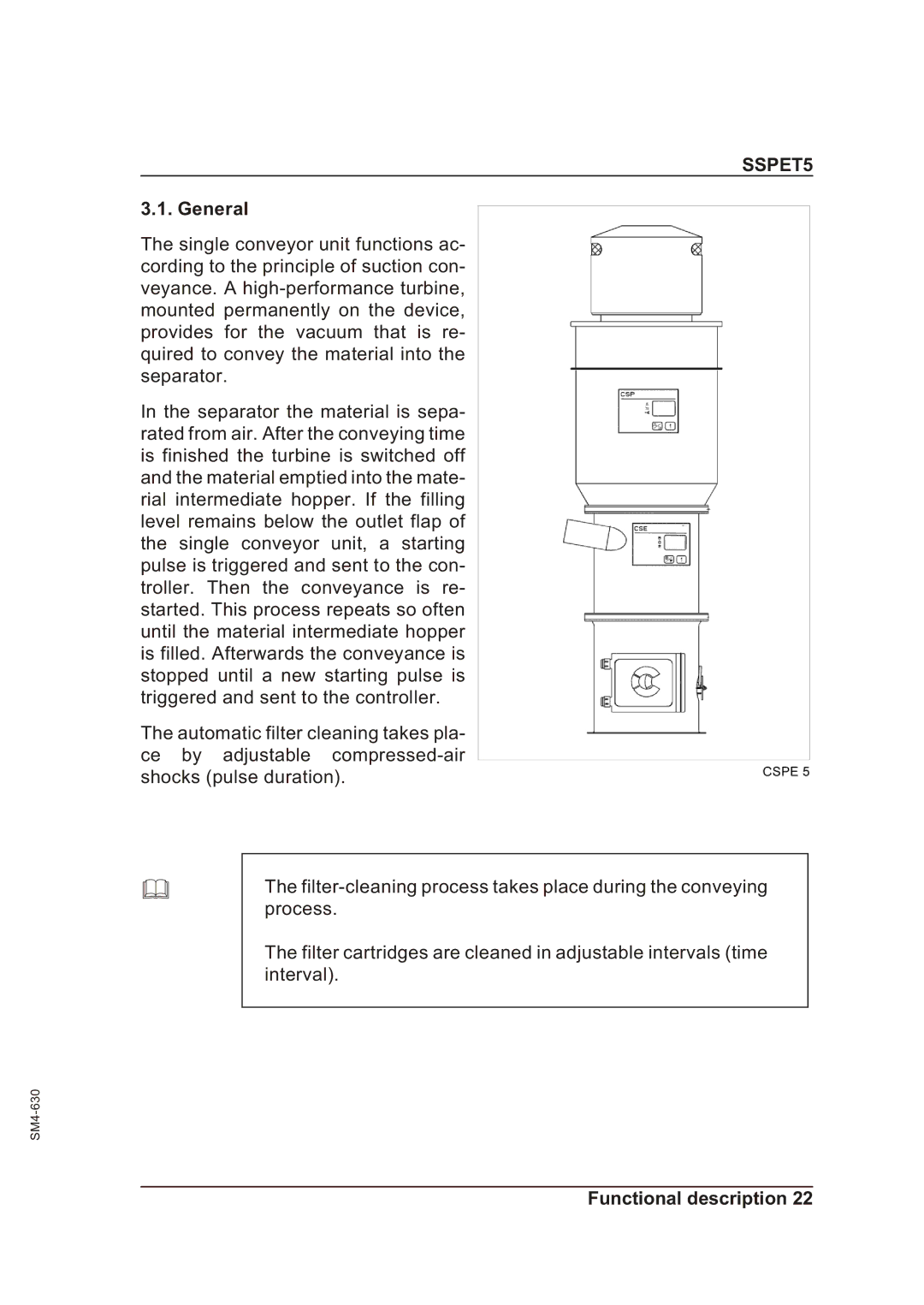

The single conveyor unit functions ac- cording to the principle of suction con- veyance. A

In the separator the material is sepa- rated from air. After the conveying time is finished the turbine is switched off and the material emptied into the mate- rial intermediate hopper. If the filling level remains below the outlet flap of the single conveyor unit, a starting pulse is triggered and sent to the con- troller. Then the conveyance is re- started. This process repeats so often until the material intermediate hopper is filled. Afterwards the conveyance is stopped until a new starting pulse is triggered and sent to the controller.

The automatic filter cleaning takes pla- ce by adjustable

&

The

The filter cartridges are cleaned in adjustable intervals (time interval).