Preface

Toro Company 1997, 1998, 2003

Groundsmaster 3000/3000-D

Table Of Contents

Groundsmaster 3000/3000-D

Contour 82I Cutting Unit Electrical Diagrams

84I Cutting Units 72I Cutting Units

Groundsmaster 3000/3000-D

Safety Instructions

Chapter

Before Operating

Safety Groundsmaster 3000/3000-D

While Operating

Maintenance

Safety and Instruction Decals Groundsmaster

Safety 1 4 Rev. a Groundsmaster 3000/3000-D

On Control Panel

Safety and Instruction Decals Groundsmaster 3000-D

Groundsmaster 3000/3000-D 1 5 Rev. a Safety

Safety and Instruction Decals 84I Cutting Units

Safety 1 6 Rev. a

On Each Castor Arm

1 7 Rev. a Safety

On Rear of Deck On Front of Deck On Rear Of Deck

On Each Castor Arm On Deck Channels, Under Covers

Safety and Instruction Decals Contour 82I Cutting Unit

On Top of Rear Castor Chambers 2

Groundsmaster 3000/3000-D Safety

On Front Deck Hanger

On Gearbox Base On Front of Deck

Deck On Each Corner On Right Rear Top of Deck Under Cover

On Front of Deck On Rear Of Deck

Safety Groundsmaster 3000/3000-D

Product Records and Maintenance

Product Records

Product Records and Maintenance Groundsmaster 3000/3000-D

Equivalents and Conversions

Torque Specifications

Product Records and Maintenance 2 4 Rev. a

Lubrication

Traction Unit

Cutting Units

Rear Discharge 84I Cutting Unit

Contour 82I Cutting Unit

Page

Equipment Operation and Service History Report

GroundsmasterR3000 Maintenance Schedule

Annual Recommendations

GroundsmasterR3000 Daily Maintenance Check List

Maintenance Daily Maintenance Check For Week Check Item b

Service Required

B Service Required

Records

Groundsmasterr 3000-D

GroundsmasterR3000-D Maintenance Schedule

Product Records and Maintenance 2 14 Rev. B

GroundsmasterR3000-D Daily Maintenance Check List

Service

Service every 100 hours

C, and D Service Required

2 16 Rev. a

Ford VSG-411 Engine

Groundsmaster Ford VSG-411 Engine

General Information Specifications

Ford VSG-411 Engine 3 2 Rev. a Groundsmaster

Alternator Belt

Adjustments

Belt Adjustments

Cooling & Governor Fan Belts

Governor Adjustment

Ford VSG-411 Engine Groundsmaster

Check Engine Oil

Service and Repairs

Outside Temperature

Single Viscosity Oils

Change Engine Oil and Filter

Check Coolant

Cooling System Service

Maintaining Cooling System Capacity

Washing Method

General Air Cleaner Service

Service Air Cleaner

Compressed Air Method

Fuel System Service

Fuel Tank

Fuel Lines and Connections

Replacing Spark Plugs

Check Governor Oil Level

Servicing Spark Arrestor Muffler

Peugeot TUD5 Engine

Peugeot TUD5 Engine

Peugeot TUD5 Engine Groundsmaster 3000-D

Compression Test Kit TOR3003A

Air Filter Element Cleaner TOR277220

Special Tools

Valve Spring Compression Tool TOR4024T

Digital Belt Tension Tool TOR4075

Peugeot TUD5 Diesel Engine Service Tool Kit TOR4080

Injection Nozzle Tester TOR463610

Order separately

Valve Guide Seal Remover TOR4081

Injector Socket TOR4082

Torque Angle Gauge TOR4083

Camshaft Pinion Setting Tool TOR4084

Rear Main Seal Installer TOR4086

Timing Pin Set TOR4085

Front Seal Installer TOR4087

Camshaft Seal Installer TOR4088

Engine Belts

Fan Belt

Not Overfill

Change Engine Oil and Filter

Check Cooling System

El. Coolant level should be up to or above tabs In de

Rear Screen Oil Cooler Radiator

General Air Cleaner Maintenance

Servicing the Air Cleaner

Draining Fuel Filter / Water Separator

Area. Always fill fuel tank outside and wipe

Up any spilled diesel fuel before starting

Changing Fuel Filter

Priming Fuel System

Frame, Fuel Tank and Battery

Muffler and Bumper

Hood

Center Shroud and Air Cleaner

Rops

Fan Bracket and Degasser

Radiator and Cooler

4 21 Rev. a Peugeot TUD5 Engine

Engine

Peugeot TUD5 Overhaul, Checking Tuning

Peugeot TUD5 Engine Groundsmaster 3000-D

Hydraulic System and Transaxle

Hydraulic System

Hydraulic System 5 2 Rev. a

General Information

Pushing or Towing Traction Unit

Hydraulic Fitting Installation

Hydraulic Hoses

Ring Face Seal

SAE Straight Thread O-Ring Port Non-adjustable

SAE Straight Thread O-Ring Port Adjustable

Hydraulic Schematic

Lift OFF Hold LOWER/FLOAT

5 7 Rev. a Hydraulic System

Hydraulic System Transaxle

Hydraulic Components

Hydraulic System Groundsmaster 3000/3000-D

Hydraulic Pressure Test Kit TOR47009

Hydraulic Test Fitting Kit TOR4079

Measuring Container TOR4077

Hydraulic System Groundsmaster 3000/3000-D

Testing

Charge Pressure Test

Charge Pressure Priority Valve Test

Forward Traction Test

Reverse Traction Test

Implement Relief Pressure Test

Counterbalance Pressure Test and Adjustment

5 15 Rev. a Hydraulic System

Steering Valve Test

Steering Circuit Test

Cylinder Test

Hydraulic System 5 16 Rev. a

Use a tester with pressure and flow capabilities

This page is blank

Hydraulic System

Traction Pedal Linkage Adjustment

Service Brake Adjustment

Check Tire Pressure

Wheel and Tires

Lubrication

5 21 Rev. a Hydraulic System

Check Hydraulic Fluid

BP HYD TF

Change Hydraulic Oil and Filter

Traction Control Linkage

Brake Linkage

Driveshafts

Lift Arms

Steering Control

ÁÁÁÁÁÁÀÀÀ#1ÄÄÉÉÉÉÉÅÅÅ

After Repair or Replacement of Components

Removing Hydraulic System Components

Manifold Block

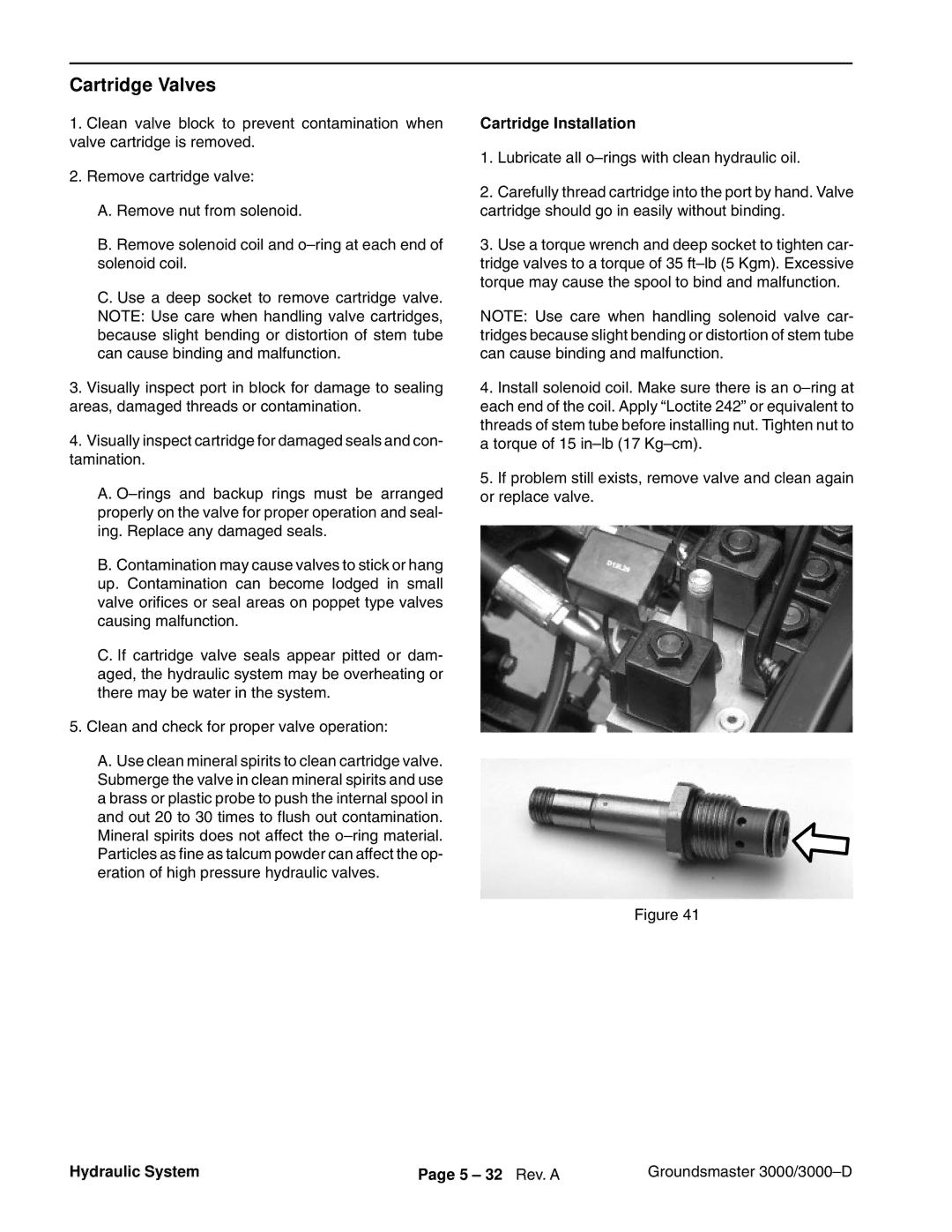

Cartridge Installation

Cartridge Valves

Hydraulic System 5 32 Rev. a

Lift Cylinder

Steering Cylinder

Auxiliary Hydraulic Pump Model 30726 Hydraulic Kit

5 35 Rev. a Hydraulic System

Transaxle Service

Electrical System

Electrical Schematics, Wiring Diagrams, and Harness Drawings

Electrical System Groundsmaster 3000/3000-D

Multimeter

Skin-Over Grease

Troubleshooting Groundsmaster

Starting Problems

Problem Possible Causes

General Run and Transport Problems Groundsmaster

Cutting Unit Operating Problems Groundsmaster

6 5 Rev. a Electrical System

Troubleshooting Groundsmaster 3000-D

General Run and Transport Problems GM 3000-D

Cutting Unit Operating Problems GM 3000-D

6 7 Rev. a Electrical System

Electrical System Quick Checks

Battery Test Open Circuit Test

Voltage Measured Battery Charge Level

Glow Plug System Test GM 3000-D

Component Identification and Testing

Ignition Switch

Diode Circuit Boards

Neutral Switch

Seat Switch

6 11 Rev. a Electrical System

Hydraulic Valve Solenoids

Hour Meter

Electrical System 6 12 Rev. a

Cruise Control Coil Optional

PTO Clutch Coil

6 13 Rev. a Electrical System

Fuel Sender

Fuel Gauge

Electrical System 6 14 Rev. a

Relay Testing

Fuse Testing

Relays and Fuses

Ampere Thermal Breaker GM 3000-D

Electrical System 6 16 Rev. a

Fuel Stop Solenoid GM 3000-D

Place Testing

Live testing

6 17 Rev. a Electrical System

Injection Advance Solenoid GM 3000-D

Electrical System 6 18 Rev. a

Test Equipment

Testing for DC Current Output Fig

Alternator GM 3000-D

6 19 Rev. a Electrical System

Temperature Sender GM 3000-D

Electrical System 6 20 Rev. a

Testing with the Engine Off

Temperature Gauge GM 3000-D

Oil Pressure Switch GM 3000-D

Testing with the Engine On

Temperature Sending Unit GM 3000-D

Electrical System 6 22 Rev. a

Transport Solenoid GM 3000-D

Glow Plugs GM 3000-D

6 23 Rev. a Electrical System

H2O in Fuel Sensor GM 3000-D

Disconnect connector from the sensor. Unscrew

Coolant Level Sensor GM 3000-D

Indicator Lights and Circuits GM 3000-D

Glow Plug Indicator Light

Ford Engine VSG-411 Electrical Component Locations GM3000

Electrical System

Handle the hot oil with extreme care to prevent

Temperature Gauge GM

Thermistor GM

Personal injury or fire

Oil Pressure Switch GM

High Temperature Switch

Anti-Dieseling Valve Solenoid GM

Indicator Lights and Circuits GM

Verify Interlock System Operation

Battery Maintenance

Important Before cleaning the battery, tape or

Battery Service

Inspection, Maintenance, and Testing

Caps are on tightly

Minimum Battery Electrolyte

Charging

Battery Charge Specific Open Circuit

Battery

Gravity Voltage

Electrical System Groundsmaster 3000/3000-D

2WD Rear Axle

7 1 Rev. a

Rear Wheel Toe-In

2WD Rear Axle Groundsmaster 3000/3000-D

Wheel and Tire Service

7 3 Rev. a

Wheel Bearing Service

Rear Axle

2WD Rear Axle Groundsmaster 3000/3000-D

4WD Rear Axle

8 1 Rev. a

4WD Rear Axle Groundsmaster 3000/3000-D

8 3 Rev. a

Check Rear Axle Lubricant

Change Rear Axle Lubricant

4WD Axle

Spindle flange

Differential shim kit

4WD Rear Axle Groundsmaster 3000/3000-D

Cutting Units

Inch Cutting Units

Specifications

Transport Latch Adjustment

Height of Cut Adjustment

Inch Cutting Units Groundsmaster 3000/3000-D

Skid Adjustment

Anti-Scalp Roller Adjustment

Bolt

Deck Pitch Adjustment

Check Gear Box Lubricant

Replace Gear Box Lubricant

Lubricate Bearings, Bushings and Gear Box

Disconnect Cutting Unit From Traction Unit

Connect Cutting Unit to Traction Unit

Install Lift Arm Ball Joints

Drive Belt Replacement

9 11 Rev. a Inch Cutting Units

Front Castor Fork Bushing Service

Castor Wheel and Bearing Service

Cutter Blade Removal and Installation

Inspecting and Sharpening Blade

Blade Spindle Service

Removing Spindle Housing Assembly

Disassembly

Installing Spindle, Bearings Seals Into Spindle Housing

9 17 Rev. a Inch Cutting Units

Correcting Cutting Unit Mismatch

Gearbox

Shaft End Play Adjustment

Drive Shaft

Inch Cutting Units Groundsmaster 3000/3000-D

Contour 82I Cutting Unit

10 1 Rev. C Contour 82 Cutting Unit

Specifications

Front Castor Wheels

Rear Castor Wheels

Contour 82 Cutting Unit Groundsmaster 3000/3000-D

Rear Deck Chain

Deck Pitch Adjustment

Grease Bearings and Bushings

Needle Valve Latch Cover

Connect Cutting Unit to Traction Unit

Castor arm tube Bushing

60 80 ft-lb 11 Kgm Castor wheel Bearing Front Caster Fork

Cutting Blade Removal and Installation

Inspecting and Sharpening Blade

Correcting Cutting Unit Mismatch

Chamber Pivot Service

Cutting Unit Contour

Contour 82 Cutting Unit 10 16 Rev. a

Front Part Of Blade

Inch 6 mm

Lift Arm Ball Joint Installation

Hydraulic Motor and Blade

10 19 Rev. C Contour 82 Cutting Unit

Contour 82 Cutting Unit 10 20 Rev. C

Bearing cavity of the housing. If grease does not

Assembly

Important When greasing spindles, grease

Passes into the center of the shaft and out to fill

Hydraulic Assembly

Contour 82 Cutting Unit 10 22 Rev. C

72I Cutting Units

Specifications

Guardian Recycler

Height of Cut Adjustment

Skid Flange nut

Gage Wheel Adjustment Rear Discharge Cutting Unit

Deck Pitch Adjustment

After 50 hours of operation

Grease Bearings, Bushings and Gear Box

Disconnect Cutting Unit From Traction Unit

11 11 Rev. a Inch Cutting Units

Gear Box Plate Capscrews & Nuts

Wavey Washer

60 80 ft-lb 8 11 Kgm Bearing Spacer

Cutter Blade Removal

Inspecting and Sharpening Blade

85 110 ft-lb 12 15 Kgm

Inch Cutting Units 11 18 Rev. a

Correcting Cutting Unit Mismatch

170 190 in-lb 196 219 Kgcm

Shaft End Play Adjustment

Drive Shaft

Electrical Diagrams

Electrical Diagrams Groundsmaster 3000/3000-D

Electrical Schematic

Optional

Start Circuits

Run Circuits

Temp Gauge

Wiring Diagram Rear Section

Wiring Diagram Front Section

Gauge Hour Ignition Switch Hold SW PTO Switch Override

Harness Drawing Rear Section

Harness Drawing Front Section

All relays and solenoids are shown as de-energized

Crank Circuits

Optional Cruise Control

Wiring Diagram Rear Section

Wiring Diagram Front Section

Switch Ground Sender

Input Power