Features and Benefits

Quality And ReliabilityTesting

•All Precedent™ designs were rigorously rain tested at the factory to ensure water integrity.

•Actual shipping tests were performed to determine packaging requirements. Units were test shipped around the country to determine the best packaging.

•Factory shake and drop tests were used as part of the package design process to help assure that the unit arrives at the job site in top condition.

•Rigging tests include lifting a unit into the air and letting it drop one foot, assuring that the lifting lugs and rails hold up under stress.

•We perform a 100% coil leak test at the factory.The evaporator and condenser coils are leak tested at 200 psig and pressure tested to 450 psig.

•All parts are inspected at the point of final assembly.

•Every unit receives a 100% unit run test before leaving the production line to make sure it lives up to rigorousTrane requirements.

We test designs at our factory not on our customers!

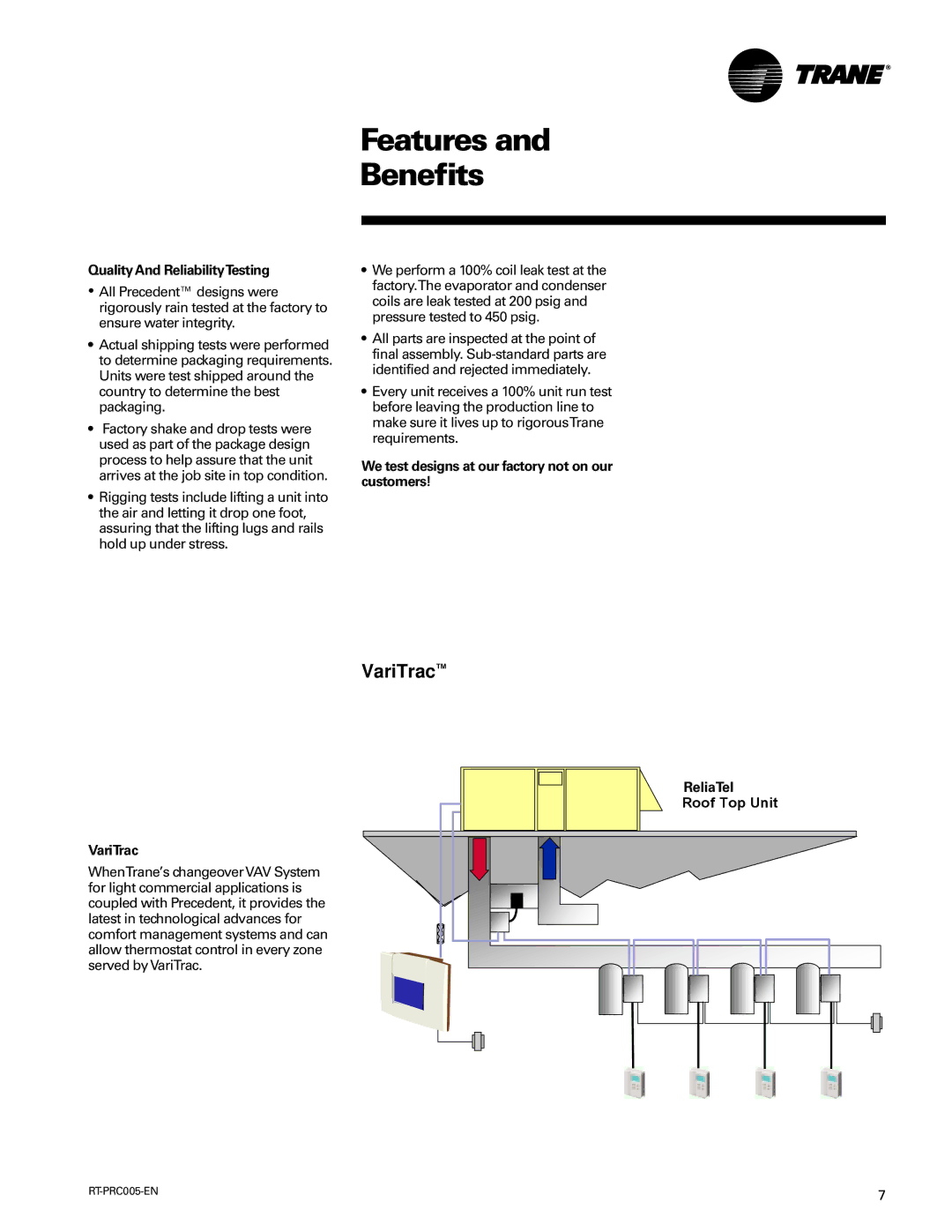

VariTrac™

VariTrac

WhenTrane’s changeover VAV System for light commercial applications is coupled with Precedent, it provides the latest in technological advances for comfort management systems and can allow thermostat control in every zone served byVariTrac.

ReliaTel |

Roof Top Unit |

7 |