Accelerating the World of Cooking

For further information call

Important Safety Information Please Read First

Table of Contents

Microwave System

Oven Door

Schematics and Schematic Components

Service Parts and Illustrations

Convection Circuit

IR Element and Catalytic Converter

Important Safety Instructions

Grounding Instructions

Installation, Specifications, and Maintenance

Dimensions

Standard Features

Power Supply North America

Construction

Power Supply Europe, Asia-Pacific

Power Supply Latin America

Power Supply South Korea

Built-In Installation Figure

Installation Near Open Heat Source Figure

Setup

Initial Power-up

Oven Restraint Kit TC3-0242 KIT

Stacking

Remove the Lower Access Panel

Remove and Clean the Cooking Surface

Clean Oven Interior

Clean Lower Access Panel Area

Theory of Operation

Chapter

Set Temperature, Cook Cavity Ccsp

Set Temperature, IR Element Irsp and Irsi

Actual Temperature, Cook Cavity TCC

Actual Temperature, IR Element TIR

Fault Code

Keypad

Display

Self-Test Stest

Fault Codes

F2 Cook Temperature Low

F1 Blower Running Status Bad

F3 Magnetron Current Low

F4 Door Monitor Defective

F5 Magnetron Over Temperature

Thermocouple temperature is below the indicated limit

F7 Thermocouple Open

F8 Heat Low

Control System

Mech

VDC Power Supply

Interlock Switches

K1 Mechanical Relay

K2 Mechanical Relay

Faults Screen

Blower Speed Screen

Self-Test Function Screen

Heater Test Screen

Diagnostic Display Screen

Electronic Compartment Temperature Screen

Changing the Cook Chamber Temperature

Cooks Screen

Altering a Recipe

Snooze Mode

Loading a Menu from a Smart Card

Done Screen

Time Screen

Function/Screen

Enter Key Code

Smart Card Reader Cable

Reference page 54 for a schematic of the I/O control board

Board J3 connector Replace I/O control board

Pin connector

If not, correct the voltage supply

VAC is going to the motor controller via pins 2

Troubleshooting

Refer to page 50 for motor controller troubleshooting

Detailed troubleshooting

If high-limit is not tripped, follow the instructions below

Microwave System

Voltage Doubler Circuit Description

Microwave System

Filament and High Voltage Terminals ORG

Magnetron

High-Voltage Transformers

Filament Transformers

F3 Fuse

Wave Guide Cover Replacement

Wiring the High-Voltage Transformers

NGC-3036Kit, Wave Guide Cover Includes Item 31 and sealant

Screws, #8, SST NGC-1047Support, Frame

Remove the wave guide cover. See Wave Guide

Wiring the Filament Transformers

Procedure for Measuring RF Leakage

Testing the High-Voltage Diode

How to Check a Diode

How to Check a Capacitor

How to Check a High-Voltage or Filament Transformer

Magnetron

Components

Remove the top and right side covers

Back and Enter keys, enter the code 9-4-2-8 and press Enter

HV capacitor shorted or failing follow troubleshooting on

Voltage Transformers

Mgtron soft key. Voltage present should be 200 +/- 10%

Unplug the oven and replace relay if necessary

Troubleshooting see F4 Monitor

Primary and secondary, the control would have recorded

Occurrence. See page 25 as well as Oven Door for

Energizing the Microwave System

Oven Door

Oven Door

Oven Burn-In Procedure

Critical Adjustment Notes

31 for proper procedure

Primary and Secondary Interlock Switch Adjustments and Parts

Assembly Notes

PPHD, Cres

5963

Adjusting the Primary Interlock Switch NEW Switch Setup

80 81

DIA

101

98 AR

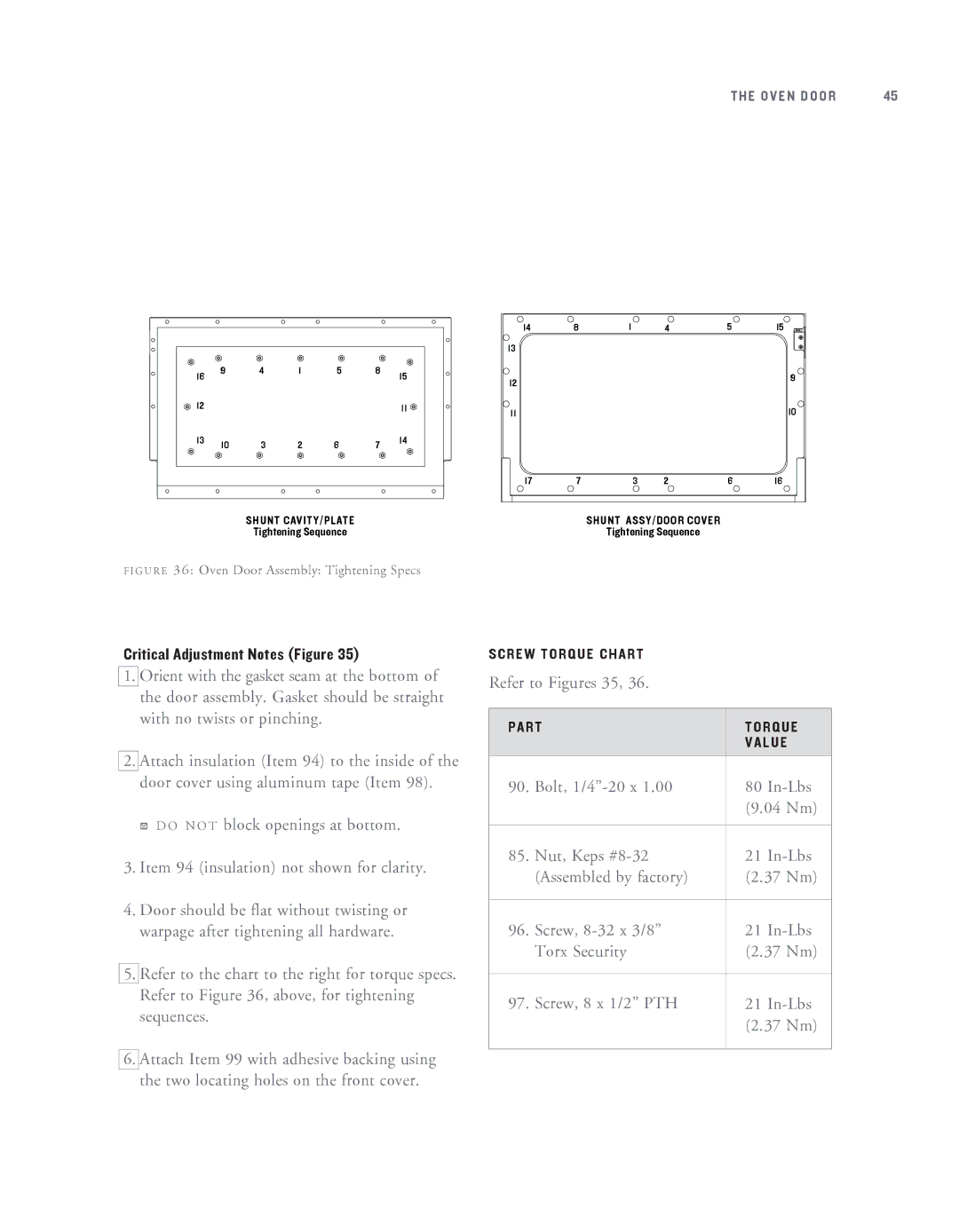

Critical Adjustment Notes Figure

Refer to Figures 35

Interlock switch status

Actuator and toggle OK Check adjustment and wiring on

New setup for the proper adjustment procedure

Door does not close freely Remove obstructions or readjust

Convection Circuit

Main Convection Heater

Motor Controller Bmsc

High Limit Thermostat

Convection Motor

109 110 113 111

114 105 104 103 102 107

108

106

Replace motor. For access to motor shaft, remove top panel

† Thermostat tripped Reset and determine why the thermostat

Cook Door Open Message Verify which switch is not actuating

Readjust. See pages

Verify motor spins freely

† Motor spins freely Verify motor windings see table below

Disconnect control wiring

Plug on schematics pages 55-63 while incrementing blower

Converter

Removing the IR Element

IR Element

Catalytic Converter

Removing and Installing the Catalytic Converter

Installing a New IR Element

119

122

Schematics and Schematic Components

Low Voltage Components

Wire Harness Replacement P/Ns

Line Voltage Components

Board Schematic

Schematic Tornado NGC

MAG

Schematic Tornado Ngcew

Schematic Tornado Ngced

Schematic Brazil NGC

Service Parts and Illustrations

Control System

Relay

Service Parts and Illustrations

Microwave System

Monitor Circuit Shown in Failsafe State

Microwave System Parts

Wave Guide/Wave Guide Cover Parts

Oven Door

SBK

Primary and Secondary Interlock Switch Parts

Door Switch Parts

Monitor Safety Switch Parts

Primary Safety Switch Parts

80 81 Secondary and Monitor Safety Switch Parts

100

Oven Door Parts

Convection Circuit Block Diagram

Convection Circuit

109 110 113 111 112 Convection Circuit Parts

114 105 104 103 102 107 108 106

Wire Harness Replacement P/N

123 Old Switch Setup 126

IR Element and Catalytic Converter

122 119

129 132 144 139 141

135 137 138 133 134

150 Screw, #8-32 x 3/8, Pphd NGC-2011-8

147 150 162 157 159

153 155 156 151 152

Comprehensive Part List

Comprehensive Part List

Comprehensive Part List

Relay, K7, Magnetron Fan, Standard Europe, Asia-Pacific MPh

Smart Card, Programmed call TurboChef for Part Numbers

800.90T U R B O or