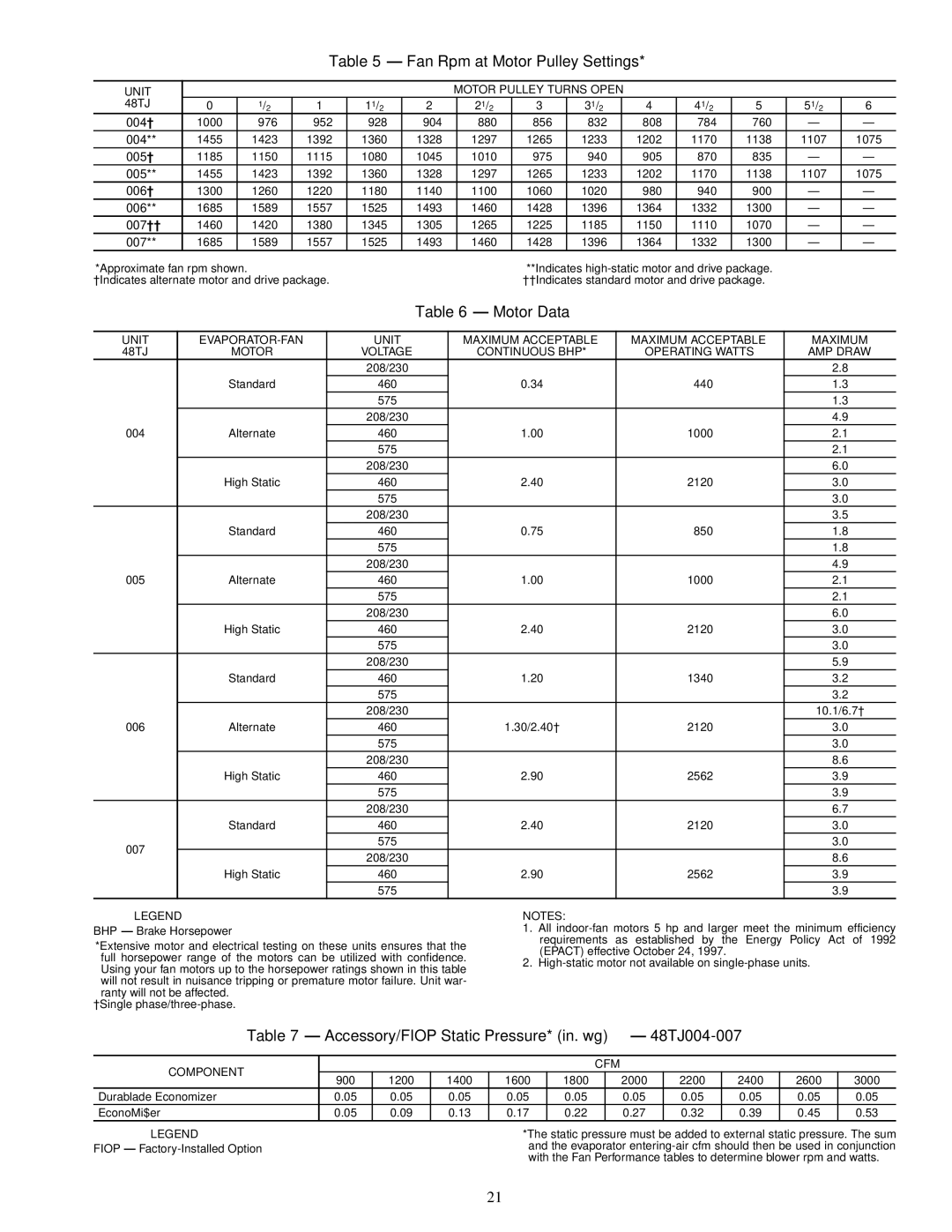

Table 5 — Fan Rpm at Motor Pulley Settings*

UNIT |

|

|

|

|

| MOTOR PULLEY TURNS OPEN |

|

|

|

|

| ||||

48TJ | 0 | 1/2 | 1 | 11/2 | 2 |

| 21/2 | 3 | 31/2 |

| 4 | 41/2 | 5 | 51/2 | 6 |

004† | 1000 | 976 | 952 | 928 | 904 |

| 880 | 856 | 832 |

| 808 | 784 | 760 | — | — |

004** | 1455 | 1423 | 1392 | 1360 | 1328 |

| 1297 | 1265 | 1233 |

| 1202 | 1170 | 1138 | 1107 | 1075 |

005† | 1185 | 1150 | 1115 | 1080 | 1045 |

| 1010 | 975 | 940 |

| 905 | 870 | 835 | — | — |

005** | 1455 | 1423 | 1392 | 1360 | 1328 |

| 1297 | 1265 | 1233 |

| 1202 | 1170 | 1138 | 1107 | 1075 |

006† | 1300 | 1260 | 1220 | 1180 | 1140 |

| 1100 | 1060 | 1020 |

| 980 | 940 | 900 | — | — |

006** | 1685 | 1589 | 1557 | 1525 | 1493 |

| 1460 | 1428 | 1396 |

| 1364 | 1332 | 1300 | — | — |

007†† | 1460 | 1420 | 1380 | 1345 | 1305 |

| 1265 | 1225 | 1185 |

| 1150 | 1110 | 1070 | — | — |

007** | 1685 | 1589 | 1557 | 1525 | 1493 |

| 1460 | 1428 | 1396 |

| 1364 | 1332 | 1300 | — | — |

*Approximate fan rpm shown.

†Indicates alternate motor and drive package.

**Indicates

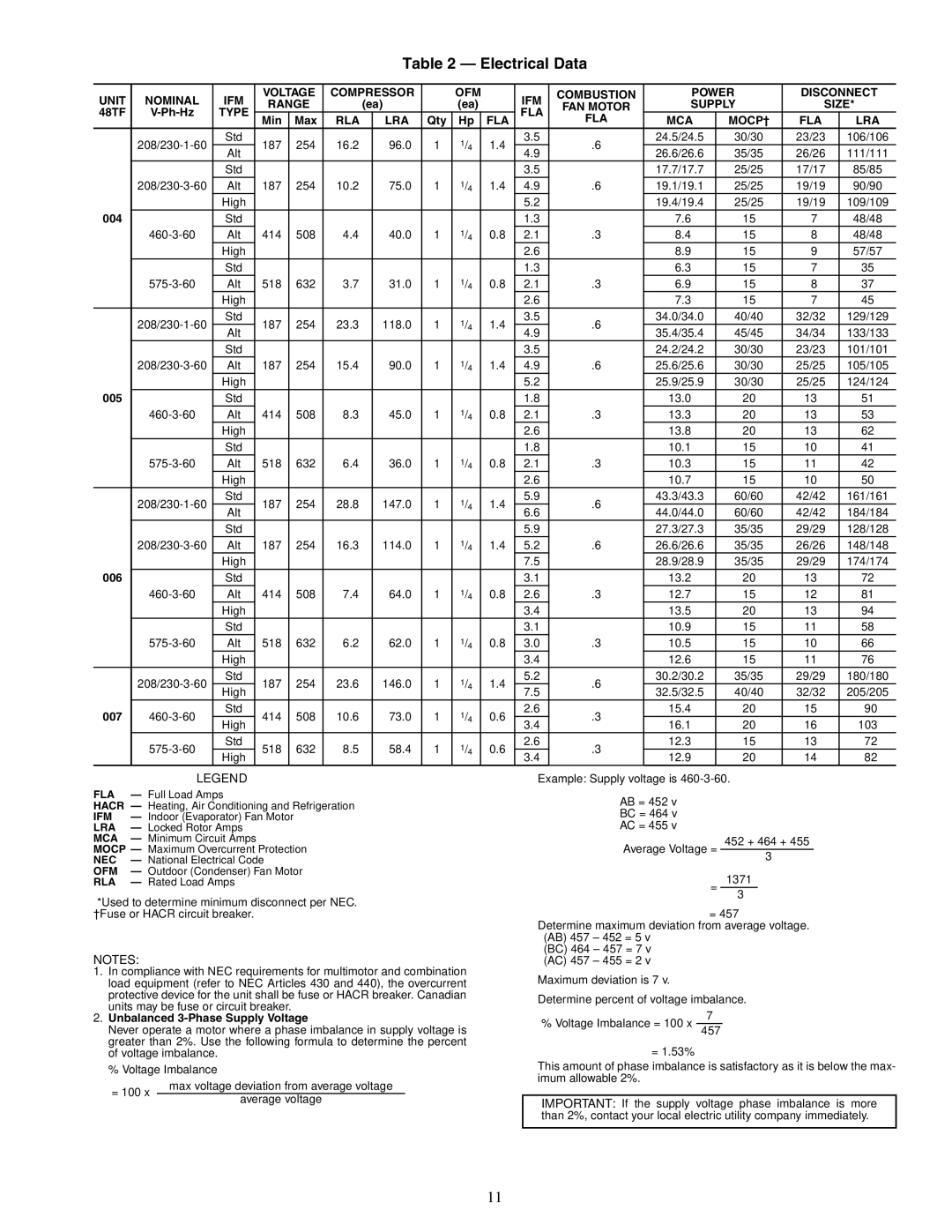

Table 6 — Motor Data

UNIT | UNIT | MAXIMUM ACCEPTABLE | MAXIMUM ACCEPTABLE | MAXIMUM | |

48TJ | MOTOR | VOLTAGE | CONTINUOUS BHP* | OPERATING WATTS | AMP DRAW |

|

| 208/230 |

|

| 2.8 |

| Standard | 460 | 0.34 | 440 | 1.3 |

|

| 575 |

|

| 1.3 |

|

| 208/230 |

|

| 4.9 |

004 | Alternate | 460 | 1.00 | 1000 | 2.1 |

|

| 575 |

|

| 2.1 |

|

| 208/230 |

|

| 6.0 |

| High Static | 460 | 2.40 | 2120 | 3.0 |

|

| 575 |

|

| 3.0 |

|

| 208/230 |

|

| 3.5 |

| Standard | 460 | 0.75 | 850 | 1.8 |

|

| 575 |

|

| 1.8 |

|

| 208/230 |

|

| 4.9 |

005 | Alternate | 460 | 1.00 | 1000 | 2.1 |

|

| 575 |

|

| 2.1 |

|

| 208/230 |

|

| 6.0 |

| High Static | 460 | 2.40 | 2120 | 3.0 |

|

| 575 |

|

| 3.0 |

|

| 208/230 |

|

| 5.9 |

| Standard | 460 | 1.20 | 1340 | 3.2 |

|

| 575 |

|

| 3.2 |

|

| 208/230 |

|

| 10.1/6.7† |

006 | Alternate | 460 | 1.30/2.40† | 2120 | 3.0 |

|

| 575 |

|

| 3.0 |

|

| 208/230 |

|

| 8.6 |

| High Static | 460 | 2.90 | 2562 | 3.9 |

|

| 575 |

|

| 3.9 |

|

| 208/230 |

|

| 6.7 |

| Standard | 460 | 2.40 | 2120 | 3.0 |

007 |

| 575 |

|

| 3.0 |

| 208/230 |

|

| 8.6 | |

|

|

|

| ||

| High Static | 460 | 2.90 | 2562 | 3.9 |

|

| 575 |

|

| 3.9 |

LEGEND

BHP — Brake Horsepower

*Extensive motor and electrical testing on these units ensures that the full horsepower range of the motors can be utilized with confidence. Using your fan motors up to the horsepower ratings shown in this table will not result in nuisance tripping or premature motor failure. Unit war- ranty will not be affected.

†Single

NOTES:

1.All

2.

Table 7 — Accessory/FIOP Static Pressure* (in. wg) — 48TJ004-007

COMPONENT |

|

|

|

|

| CFM |

|

|

|

| |

900 | 1200 | 1400 | 1600 | 1800 |

| 2000 | 2200 | 2400 | 2600 | 3000 | |

|

| ||||||||||

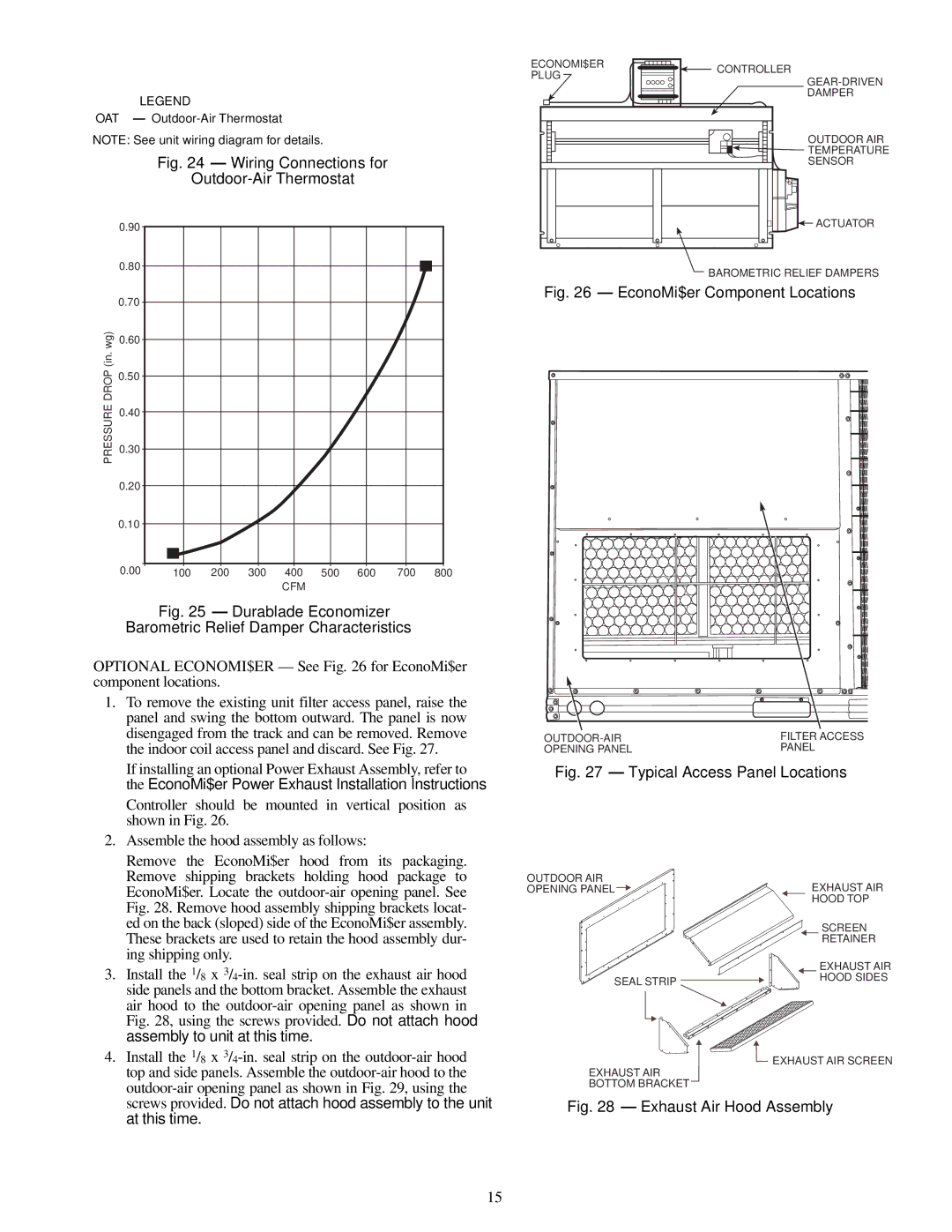

Durablade Economizer | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

EconoMi$er | 0.05 | 0.09 | 0.13 | 0.17 | 0.22 |

| 0.27 | 0.32 | 0.39 | 0.45 | 0.53 |

LEGEND |

|

|

| *The static pressure must be added to external static pressure. The sum | |||||||

FIOP — |

|

|

| and the evaporator | |||||||

|

|

|

| with the Fan Performance tables to determine blower rpm and watts. | |||||||

21