Fig. 47 — Separating Coil Sections

Lubrication

COMPRESSORS — Each compressor is charged with the correct amount of oil at the factory.

Manual

Economizer Adjustment — Refer to Optional Econo- mizer sections on pages 13 and 15.

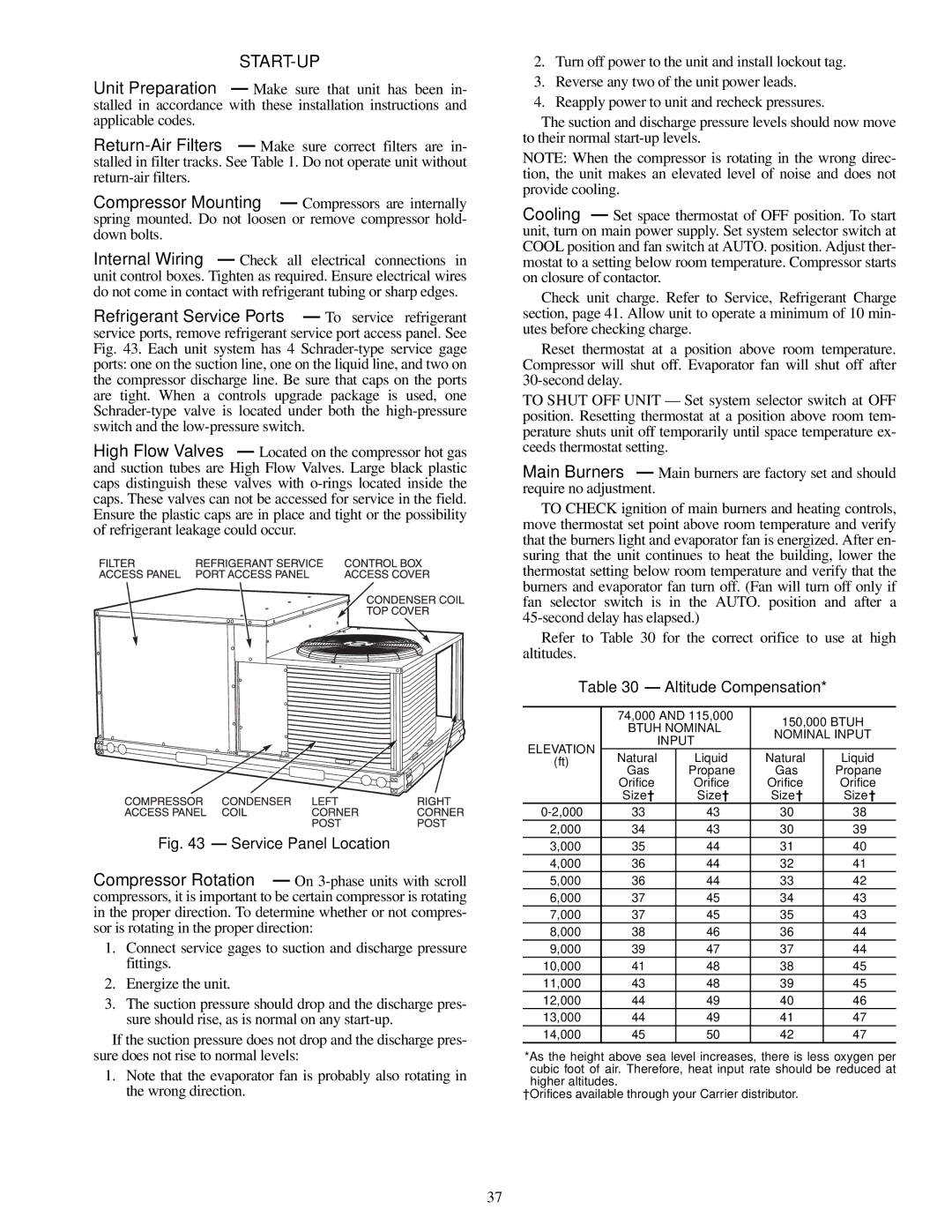

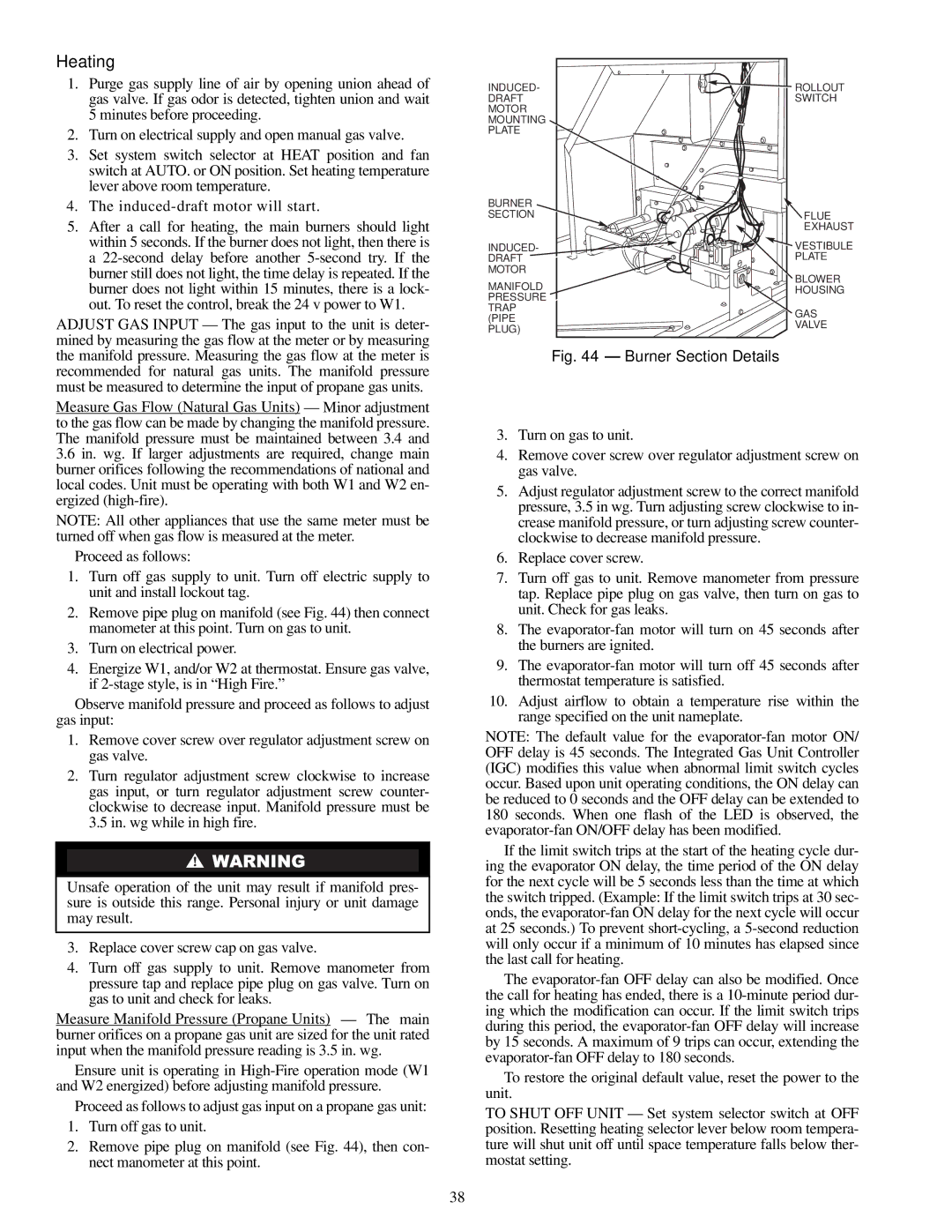

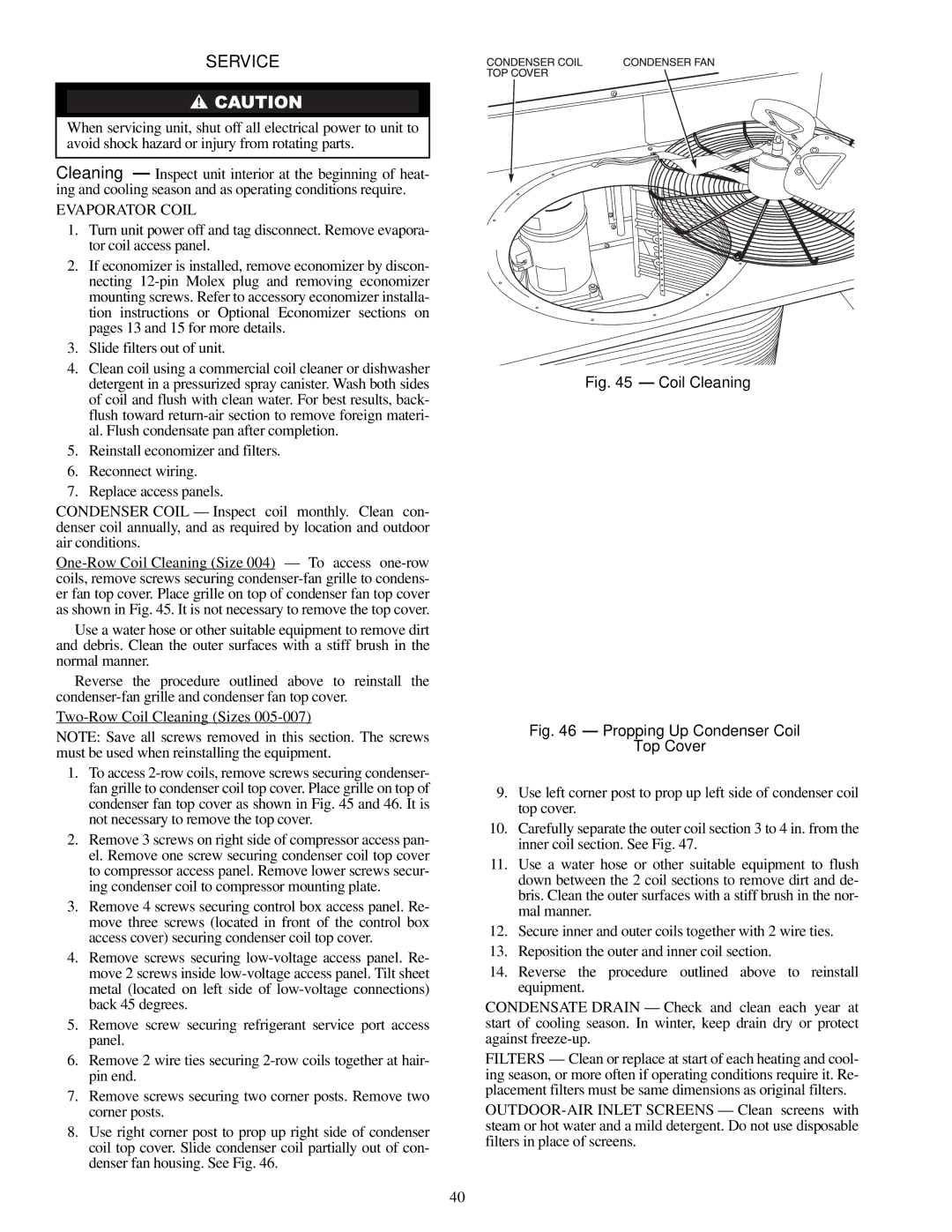

Condenser Fan Adjustment (Fig. 48) — Shut off unit power supply and tag disconnect. Remove

Belt/Pulley Adjustment — Inspect once each season, or if conditions warrant to verify belt tension and pulley align- ment are correct. Replace belt if necessary.

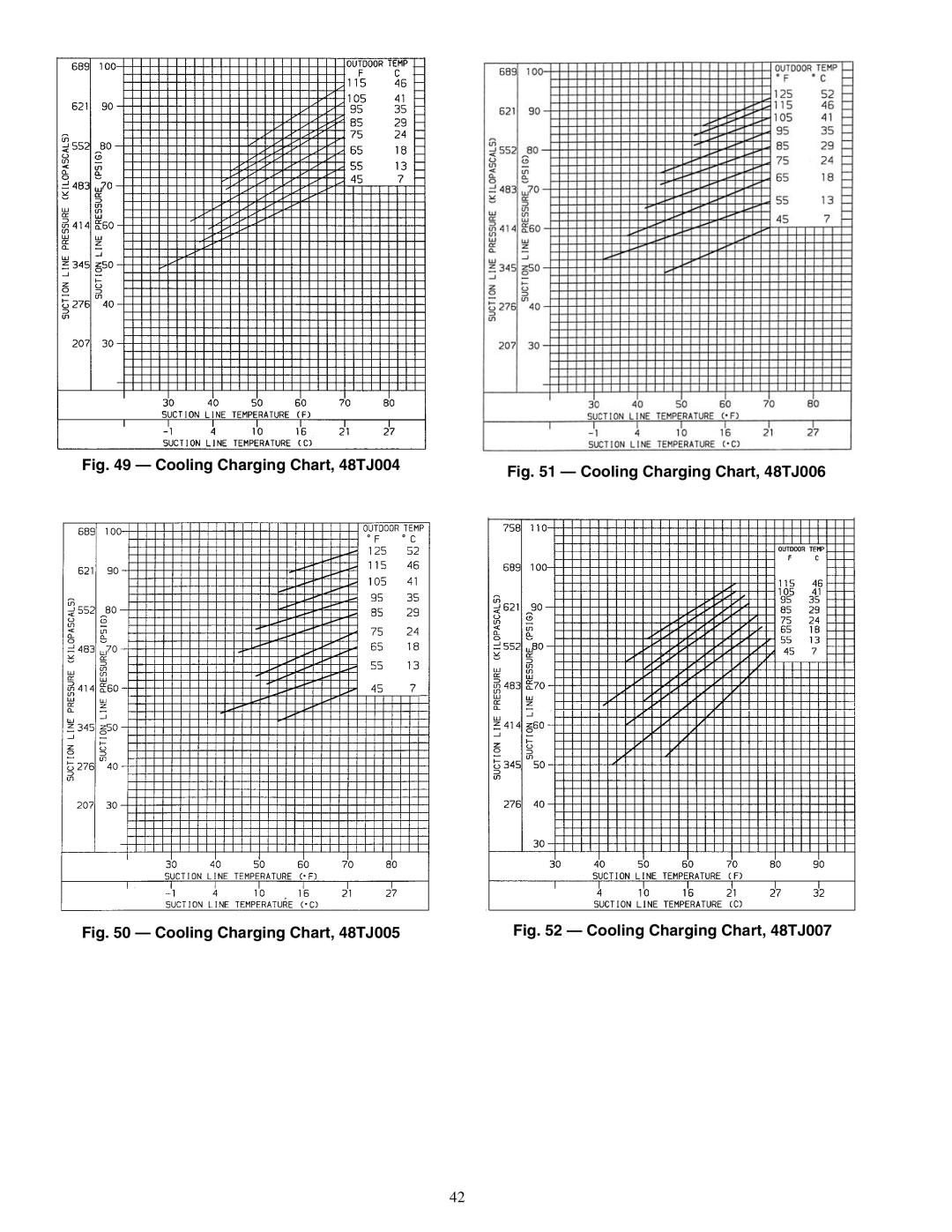

Refrigerant Charge — Amount of refrigerant charge is listed on unit nameplate (also refer to Table 1). Refer to Carrier

Unit panels must be in place when unit is operating during charging procedure. Unit must operate a minimum of 10 min- utes before checking or adjusting charge.

Fig. 48 — Condenser-Fan Adjustment

NO CHARGE — Use standard evacuating techniques. After evacuating system, weigh in the specified amount of refriger- ant. (Refer to Table 1.)

TO USE COOLING CHARGING CHART — Take the out- door ambient temperature and read the suction pressure gage. Refer to chart to determine what suction temperature should be. If suction temperature is high, add refrigerant. If suction temperature is low, carefully recover some of the charge. Recheck the suction pressure as charge is adjusted.

EXAMPLE: (Fig. 51)

Outdoor Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85 F Suction Pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80 psig Suction Temperature should be. . . . . . . . . . . . . . . . . . . . . . .68 F

(Suction Temperature may vary 5 F.)

Flue Gas Passageways — To inspect the flue collec- tor box and upper areas of the heat exchanger:

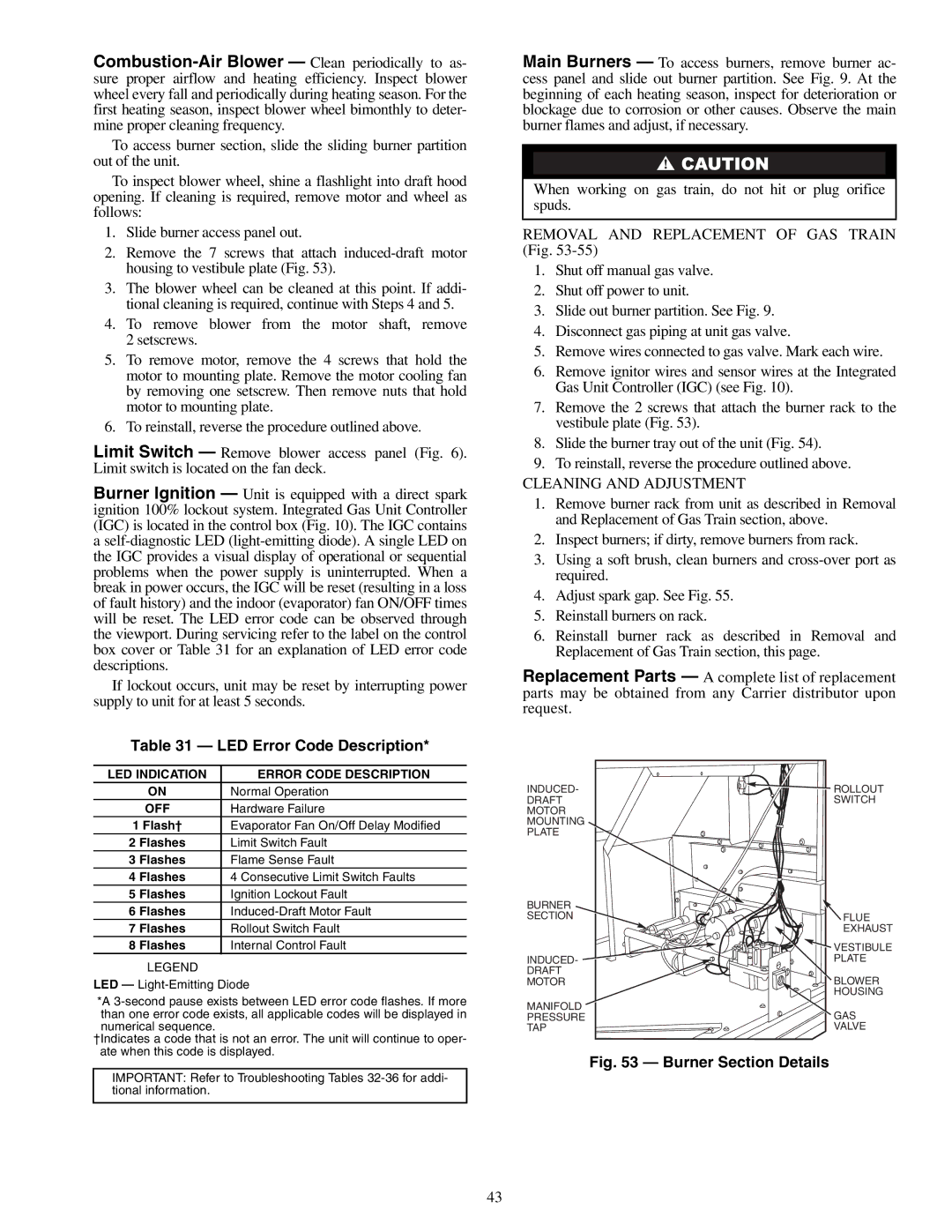

1.Remove the combustion blower wheel and motor assem- bly according to directions in

2.Remove the flue cover to inspect the heat exchanger.

3.Clean all surfaces as required using a wire brush.

41