Table 34 — Cooling Service Analysis

PROBLEM | CAUSE | REMEDY |

Compressor and condenser fan | Power failure. | Call power company. |

will not start. | Fuse blown or circuit breaker tripped. | Replace fuse or reset circuit breaker. |

| ||

| Defective thermostat, contactor, transformer, | Replace component. |

| or control relay. |

|

| Insufficient line voltage. | Determine cause and correct. |

| Incorrect or faulty wiring. | Check wiring diagram and rewire correctly. |

| Thermostat setting too high. | Lower thermostat setting below room temperature. |

Compressor will not start | Faulty wiring or loose connections in com- | Check wiring and repair or replace. |

but condenser fan runs. | pressor circuit. |

|

| Compressor motor burned out, seized, or | Determine cause. Replace compressor. |

| internal overload open. |

|

| Defective run/start capacitor, overload, or | Determine cause and replace. |

| start relay. |

|

| One leg of | Replace fuse or reset circuit breaker. Determine |

|

| cause. |

Compressor cycles (other than | Refrigerant overcharge or undercharge. | Recover refrigerant, evacuate system, and |

normally satisfying thermostat). |

| recharge to nameplate. |

| Defective compressor. | Replace and determine cause. |

| Insufficient line voltage. | Determine cause and correct. |

| Blocked condenser. | Determine cause and correct. |

| Defective run/start capacitor, overload, or | Determine cause and replace. |

| start relay. |

|

| Defective thermostat. | Replace thermostat. |

| Faulty | Replace. |

| Restriction in refrigerant system. | Locate restriction and remove. |

Compressor operates continuously. | Dirty air filter. | Replace filter. |

| Unit undersized for load. | Decrease load or increase unit size. |

| Thermostat set too low. | Reset thermostat. |

| Low refrigerant charge. | Locate leak; repair, and recharge. |

| Leaking valves in compressor. | Replace compressor. |

| Air in system. | Recover refrigerant, evacuate system, and |

|

| recharge. |

| Condenser coil dirty or restricted. | Clean coil or remove restriction. |

Excessive head pressure. | Dirty air filter. | Replace filter. |

| Dirty condenser coil. | Clean coil. |

| Refrigerant overcharged. | Remove excess refrigerant. |

| Air in system. | Recover refrigerant, evacuate system, and |

|

| recharge. |

| Condenser air restricted or air | Determine cause and correct. |

Head pressure too low. | Low refrigerant charge. | Check for leaks; repair, and recharge. |

| Compressor valves leaking. | Replace compressor. |

| Restriction in liquid tube. | Remove restriction. |

Excessive suction pressure. | High heat load. | Check for source and eliminate. |

| Compressor valves leaking. | Replace compressor. |

| Refrigerant overcharged. | Recover excess refrigerant. |

Suction pressure too low. | Dirty air filter. | Replace filter. |

| Low refrigerant charge. | Check for leaks; repair, and recharge. |

| Metering device or low side restricted. | Remove source of restriction. |

| Insufficient evaporator airflow. | Increase air quantity. Check filter and replace if |

|

| necessary. |

| Temperature too low in conditioned area. | Reset thermostat. |

| Outdoor ambient below 25 F. | Install |

Evaporator fan will not shut off. | Time off delay not finished. | Wait for |

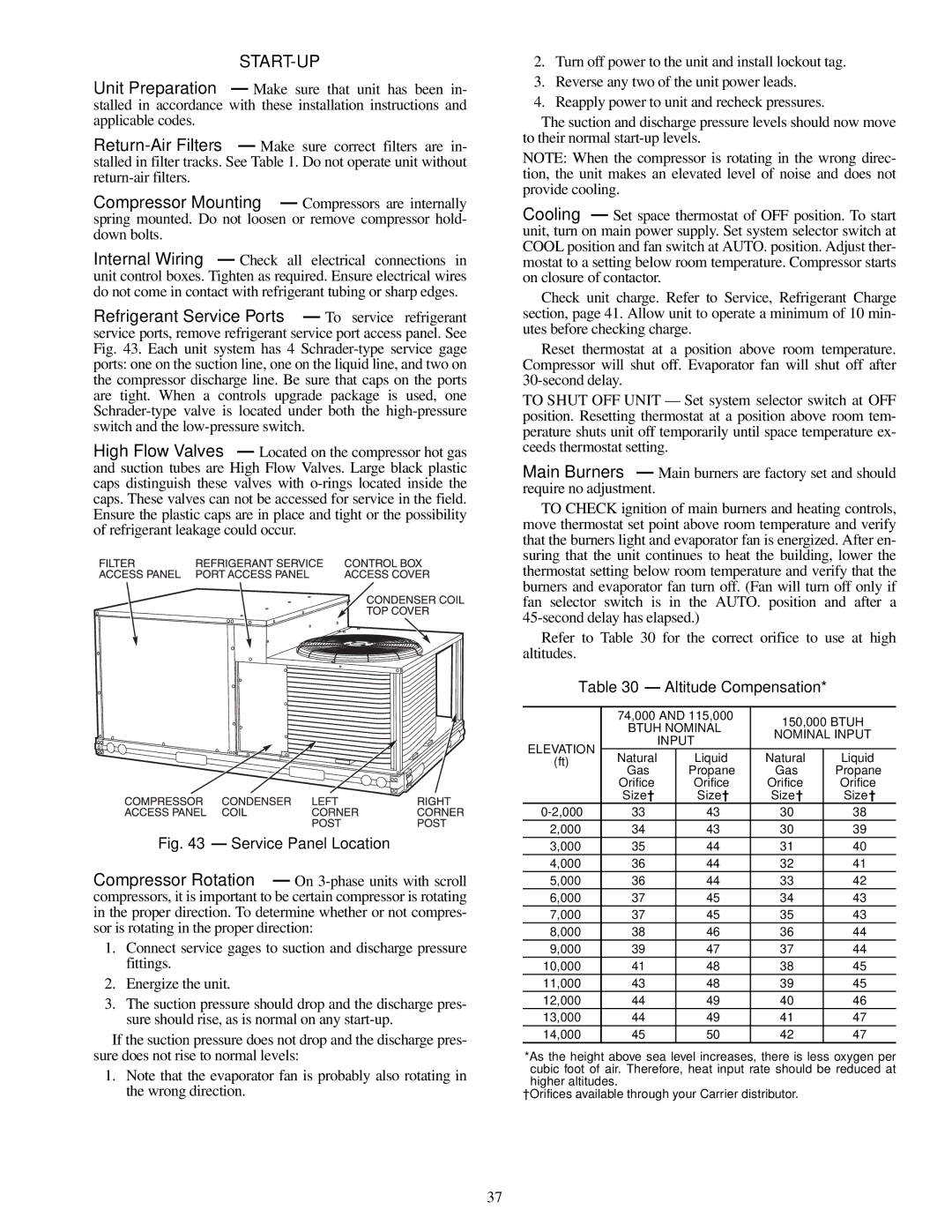

Compressor makes excessive | Compressor rotating in wrong direction. | Reverse the |

noise (48TJ007 scroll only). |

| the |

46