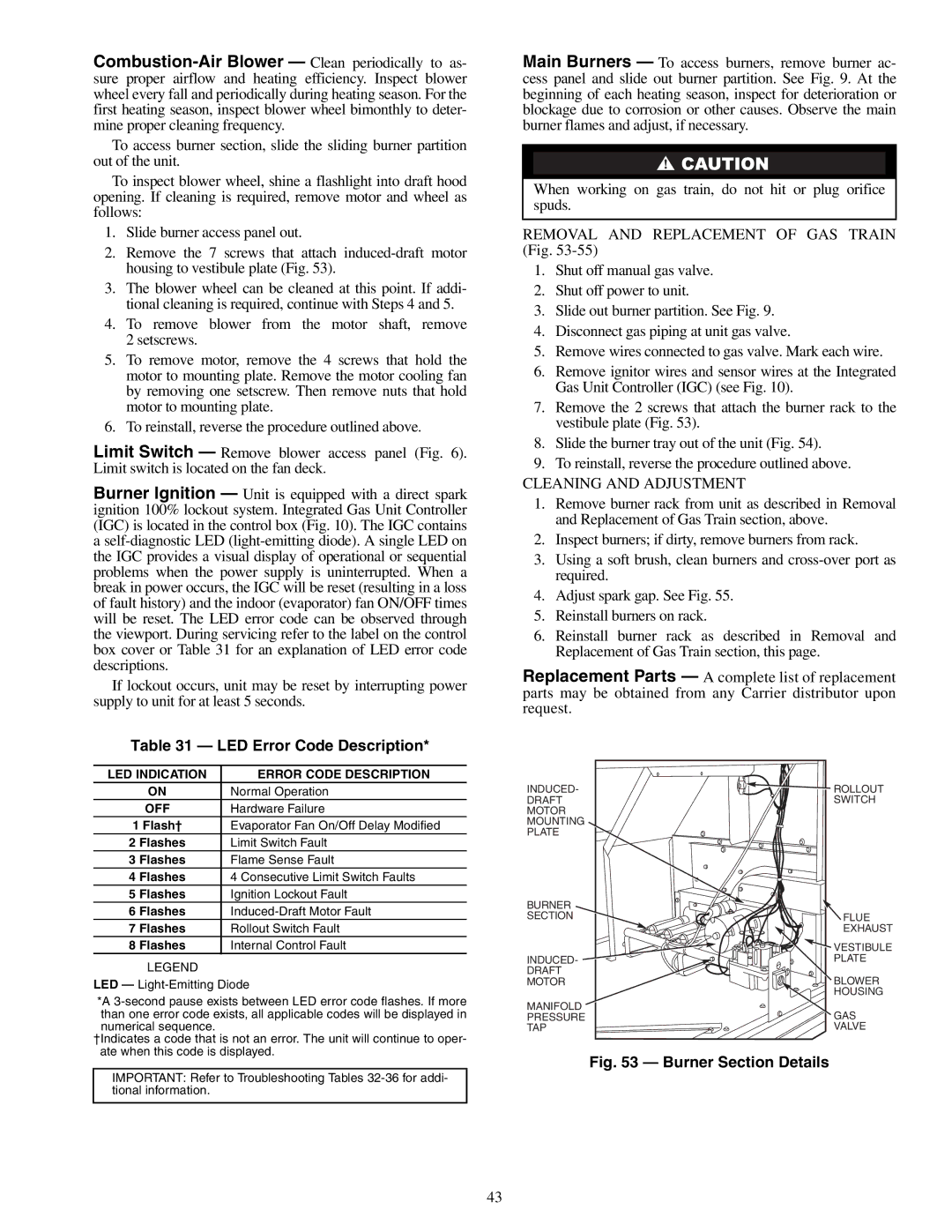

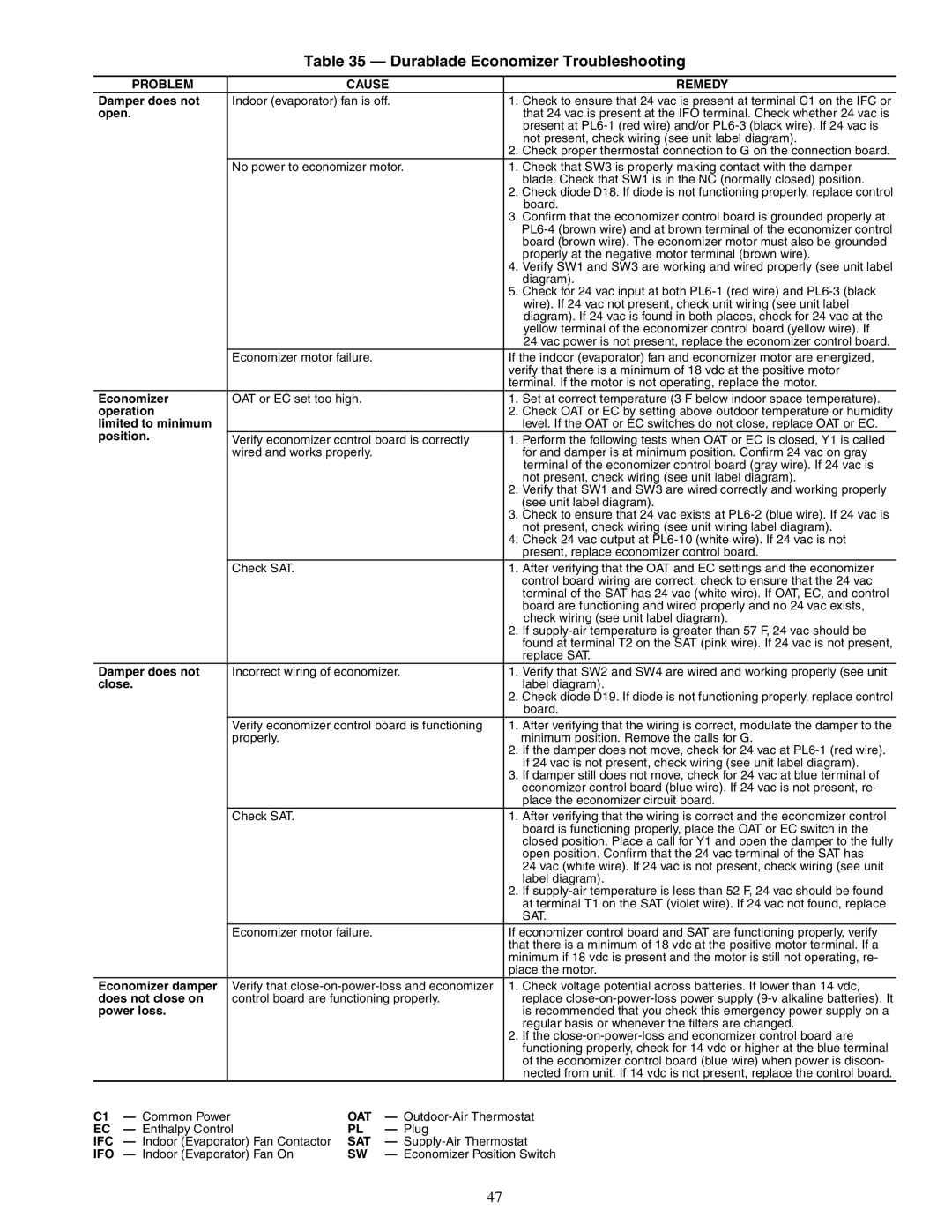

Table 35 — Durablade Economizer Troubleshooting

| PROBLEM |

|

| CAUSE |

| REMEDY | ||

Damper does not |

| Indoor (evaporator) fan is off. | 1. | Check to ensure that 24 vac is present at terminal C1 on the IFC or | ||||

open. |

|

|

|

|

| that 24 vac is present at the IFO terminal. Check whether 24 vac is | ||

|

|

|

|

|

|

|

| present at |

|

|

|

|

|

|

|

| not present, check wiring (see unit label diagram). |

|

|

|

|

|

|

| 2. | Check proper thermostat connection to G on the connection board. |

|

|

|

| No power to economizer motor. | 1. | Check that SW3 is properly making contact with the damper | ||

|

|

|

|

|

|

|

| blade. Check that SW1 is in the NC (normally closed) position. |

|

|

|

|

|

|

| 2. Check diode D18. If diode is not functioning properly, replace control | |

|

|

|

|

|

|

|

| board. |

|

|

|

|

|

|

| 3. | Confirm that the economizer control board is grounded properly at |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| board (brown wire). The economizer motor must also be grounded |

|

|

|

|

|

|

|

| properly at the negative motor terminal (brown wire). |

|

|

|

|

|

|

| 4. | Verify SW1 and SW3 are working and wired properly (see unit label |

|

|

|

|

|

|

|

| diagram). |

|

|

|

|

|

|

| 5. | Check for 24 vac input at both |

|

|

|

|

|

|

|

| wire). If 24 vac not present, check unit wiring (see unit label |

|

|

|

|

|

|

|

| diagram). If 24 vac is found in both places, check for 24 vac at the |

|

|

|

|

|

|

|

| yellow terminal of the economizer control board (yellow wire). If |

|

|

|

|

|

|

|

| 24 vac power is not present, replace the economizer control board. |

|

|

|

| Economizer motor failure. |

| If the indoor (evaporator) fan and economizer motor are energized, | ||

|

|

|

|

|

|

| verify that there is a minimum of 18 vdc at the positive motor | |

|

|

|

|

|

|

| terminal. If the motor is not operating, replace the motor. | |

Economizer |

| OAT or EC set too high. |

| 1. | Set at correct temperature (3 F below indoor space temperature). | |||

operation |

|

|

|

| 2. | Check OAT or EC by setting above outdoor temperature or humidity | ||

limited to minimum |

|

|

|

|

| level. If the OAT or EC switches do not close, replace OAT or EC. | ||

position. |

|

| Verify economizer control board is correctly | 1. | Perform the following tests when OAT or EC is closed, Y1 is called | |||

|

|

|

| wired and works properly. |

|

| for and damper is at minimum position. Confirm 24 vac on gray | |

|

|

|

|

|

|

|

| terminal of the economizer control board (gray wire). If 24 vac is |

|

|

|

|

|

|

|

| not present, check wiring (see unit label diagram). |

|

|

|

|

|

|

| 2. | Verify that SW1 and SW3 are wired correctly and working properly |

|

|

|

|

|

|

|

| (see unit label diagram). |

|

|

|

|

|

|

| 3. | Check to ensure that 24 vac exists at |

|

|

|

|

|

|

|

| not present, check wiring (see unit wiring label diagram). |

|

|

|

|

|

|

| 4. | Check 24 vac output at |

|

|

|

|

|

|

|

| present, replace economizer control board. |

|

|

|

| Check SAT. |

|

| 1. | After verifying that the OAT and EC settings and the economizer |

|

|

|

|

|

|

|

| control board wiring are correct, check to ensure that the 24 vac |

|

|

|

|

|

|

|

| terminal of the SAT has 24 vac (white wire). If OAT, EC, and control |

|

|

|

|

|

|

|

| board are functioning and wired properly and no 24 vac exists, |

|

|

|

|

|

|

|

| check wiring (see unit label diagram). |

|

|

|

|

|

|

| 2. | If |

|

|

|

|

|

|

|

| found at terminal T2 on the SAT (pink wire). If 24 vac is not present, |

|

|

|

|

|

|

|

| replace SAT. |

Damper does not |

| Incorrect wiring of economizer. | 1. | Verify that SW2 and SW4 are wired and working properly (see unit | ||||

close. |

|

|

|

|

| label diagram). | ||

|

|

|

|

|

|

| 2. Check diode D19. If diode is not functioning properly, replace control | |

|

|

|

|

|

|

|

| board. |

|

|

|

| Verify economizer control board is functioning | 1. | After verifying that the wiring is correct, modulate the damper to the | ||

|

|

|

| properly. |

|

|

| minimum position. Remove the calls for G. |

|

|

|

|

|

|

| 2. | If the damper does not move, check for 24 vac at |

|

|

|

|

|

|

|

| If 24 vac is not present, check wiring (see unit label diagram). |

|

|

|

|

|

|

| 3. | If damper still does not move, check for 24 vac at blue terminal of |

|

|

|

|

|

|

|

| economizer control board (blue wire). If 24 vac is not present, re- |

|

|

|

|

|

|

|

| place the economizer circuit board. |

|

|

|

| Check SAT. |

|

| 1. | After verifying that the wiring is correct and the economizer control |

|

|

|

|

|

|

|

| board is functioning properly, place the OAT or EC switch in the |

|

|

|

|

|

|

|

| closed position. Place a call for Y1 and open the damper to the fully |

|

|

|

|

|

|

|

| open position. Confirm that the 24 vac terminal of the SAT has |

|

|

|

|

|

|

|

| 24 vac (white wire). If 24 vac is not present, check wiring (see unit |

|

|

|

|

|

|

|

| label diagram). |

|

|

|

|

|

|

| 2. | If |

|

|

|

|

|

|

|

| at terminal T1 on the SAT (violet wire). If 24 vac not found, replace |

|

|

|

|

|

|

|

| SAT. |

|

|

|

| Economizer motor failure. |

| If economizer control board and SAT are functioning properly, verify | ||

|

|

|

|

|

|

| that there is a minimum of 18 vdc at the positive motor terminal. If a | |

|

|

|

|

|

|

| minimum if 18 vdc is present and the motor is still not operating, re- | |

|

|

|

|

|

|

| place the motor. | |

Economizer damper |

| Verify that | 1. | Check voltage potential across batteries. If lower than 14 vdc, | ||||

does not close on |

| control board are functioning properly. |

| replace | ||||

power loss. |

|

|

|

|

| is recommended that you check this emergency power supply on a | ||

|

|

|

|

|

|

|

| regular basis or whenever the filters are changed. |

|

|

|

|

|

|

| 2. | If the |

|

|

|

|

|

|

|

| functioning properly, check for 14 vdc or higher at the blue terminal |

|

|

|

|

|

|

|

| of the economizer control board (blue wire) when power is discon- |

|

|

|

|

|

|

|

| nected from unit. If 14 vdc is not present, replace the control board. |

C1 | — Common Power |

| OAT | — | ||||

EC | — Enthalpy Control | PL | — Plug |

|

| |||

IFC | — Indoor (Evaporator) Fan Contactor | SAT | — | |||||

IFO | — Indoor (Evaporator) Fan On | SW | — Economizer Position Switch | |||||

47