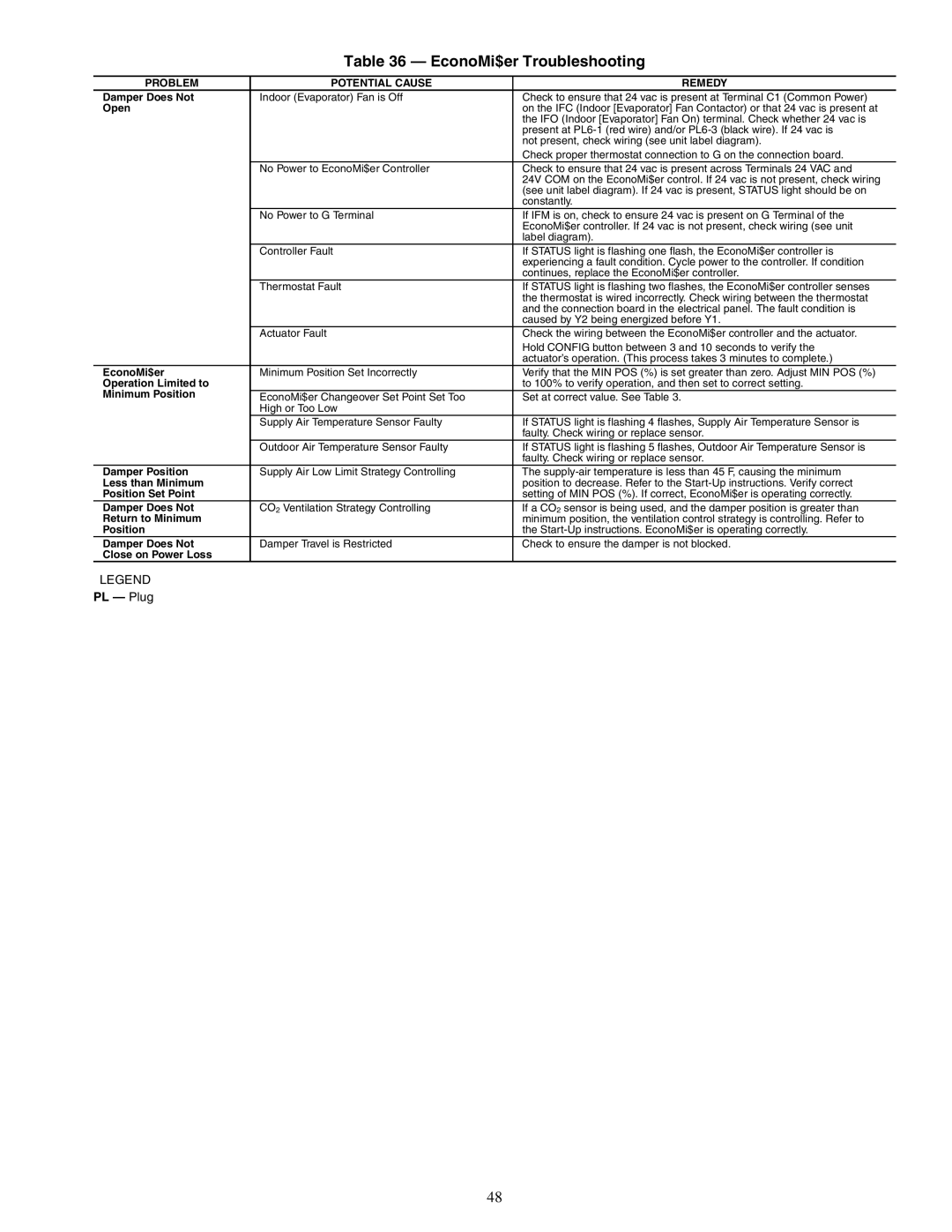

Table 36 — EconoMi$er Troubleshooting

PROBLEM | POTENTIAL CAUSE | REMEDY |

Damper Does Not | Indoor (Evaporator) Fan is Off | Check to ensure that 24 vac is present at Terminal C1 (Common Power) |

Open |

| on the IFC (Indoor [Evaporator] Fan Contactor) or that 24 vac is present at |

|

| the IFO (Indoor [Evaporator] Fan On) terminal. Check whether 24 vac is |

|

| present at |

|

| not present, check wiring (see unit label diagram). |

|

| Check proper thermostat connection to G on the connection board. |

| No Power to EconoMi$er Controller | Check to ensure that 24 vac is present across Terminals 24 VAC and |

|

| 24V COM on the EconoMi$er control. If 24 vac is not present, check wiring |

|

| (see unit label diagram). If 24 vac is present, STATUS light should be on |

|

| constantly. |

| No Power to G Terminal | If IFM is on, check to ensure 24 vac is present on G Terminal of the |

|

| EconoMi$er controller. If 24 vac is not present, check wiring (see unit |

|

| label diagram). |

| Controller Fault | If STATUS light is flashing one flash, the EconoMi$er controller is |

|

| experiencing a fault condition. Cycle power to the controller. If condition |

|

| continues, replace the EconoMi$er controller. |

| Thermostat Fault | If STATUS light is flashing two flashes, the EconoMi$er controller senses |

|

| the thermostat is wired incorrectly. Check wiring between the thermostat |

|

| and the connection board in the electrical panel. The fault condition is |

|

| caused by Y2 being energized before Y1. |

| Actuator Fault | Check the wiring between the EconoMi$er controller and the actuator. |

|

| Hold CONFIG button between 3 and 10 seconds to verify the |

|

| actuator’s operation. (This process takes 3 minutes to complete.) |

EconoMi$er | Minimum Position Set Incorrectly | Verify that the MIN POS (%) is set greater than zero. Adjust MIN POS (%) |

Operation Limited to |

| to 100% to verify operation, and then set to correct setting. |

Minimum Position | EconoMi$er Changeover Set Point Set Too | Set at correct value. See Table 3. |

| High or Too Low |

|

| Supply Air Temperature Sensor Faulty | If STATUS light is flashing 4 flashes, Supply Air Temperature Sensor is |

|

| faulty. Check wiring or replace sensor. |

| Outdoor Air Temperature Sensor Faulty | If STATUS light is flashing 5 flashes, Outdoor Air Temperature Sensor is |

|

| faulty. Check wiring or replace sensor. |

Damper Position | Supply Air Low Limit Strategy Controlling | The |

Less than Minimum |

| position to decrease. Refer to the |

Position Set Point |

| setting of MIN POS (%). If correct, EconoMi$er is operating correctly. |

Damper Does Not | CO2 Ventilation Strategy Controlling | If a CO2 sensor is being used, and the damper position is greater than |

Return to Minimum |

| minimum position, the ventilation control strategy is controlling. Refer to |

Position |

| the |

Damper Does Not | Damper Travel is Restricted | Check to ensure the damper is not blocked. |

Close on Power Loss |

|

|

LEGEND

PL — Plug

48