48TJE,TJF004

Installation, Start-Up and

Service Instructions

CONTENTS

Page

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 1

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Step 1 — Provide Unit Support . . . . . . . . . . . . . . . . . . . 1

•ROOF CURB

•SLAB MOUNT

Step 2 — Field Fabricate Ductwork . . . . . . . . . . . . . . . 2

Step 3 — Install External Trap for

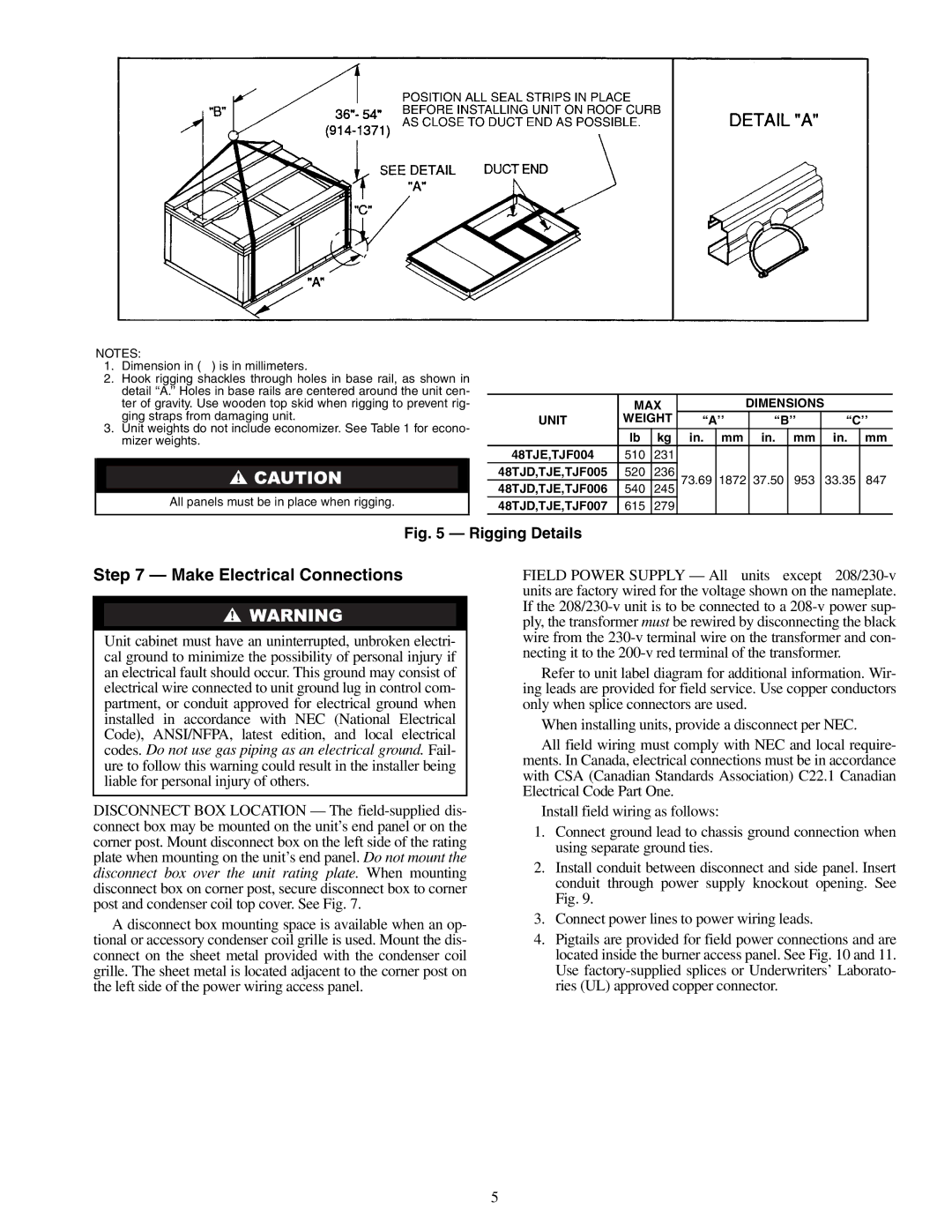

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Step 4 — Rig and Place Unit . . . . . . . . . . . . . . . . . . . . . 2

• POSITIONING |

| |

Step 5 | — Install Flue Hood | 4 |

Step 6 | — Install Gas Piping | 4 |

Step 7 | — Make Electrical Connections | 5 |

•DISCONNECT BOX LOCATION

•FIELD POWER SUPPLY

•FIELD CONTROL WIRING

•HEAT ANTICIPATOR SETTINGS

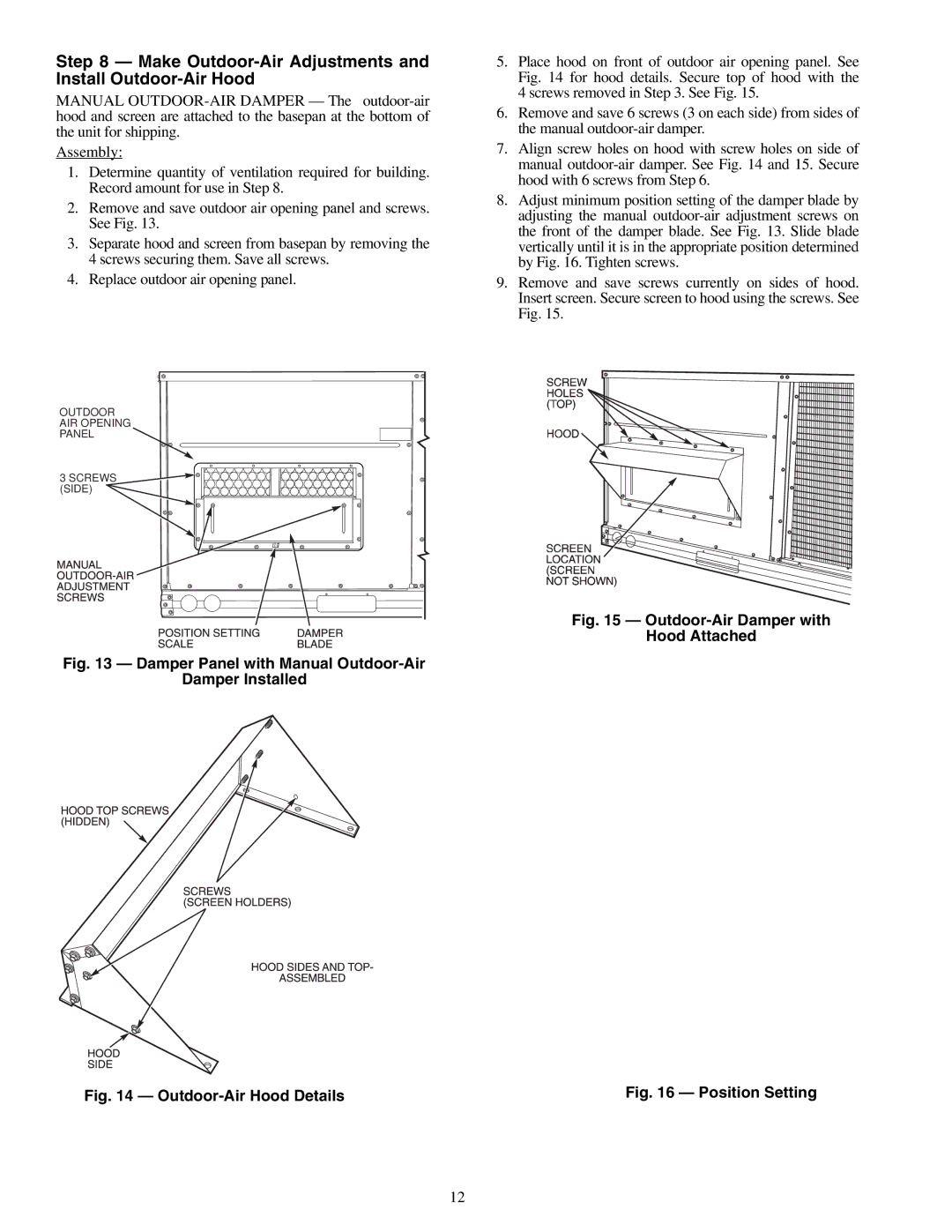

Step 8 — Make

Install

•MANUAL

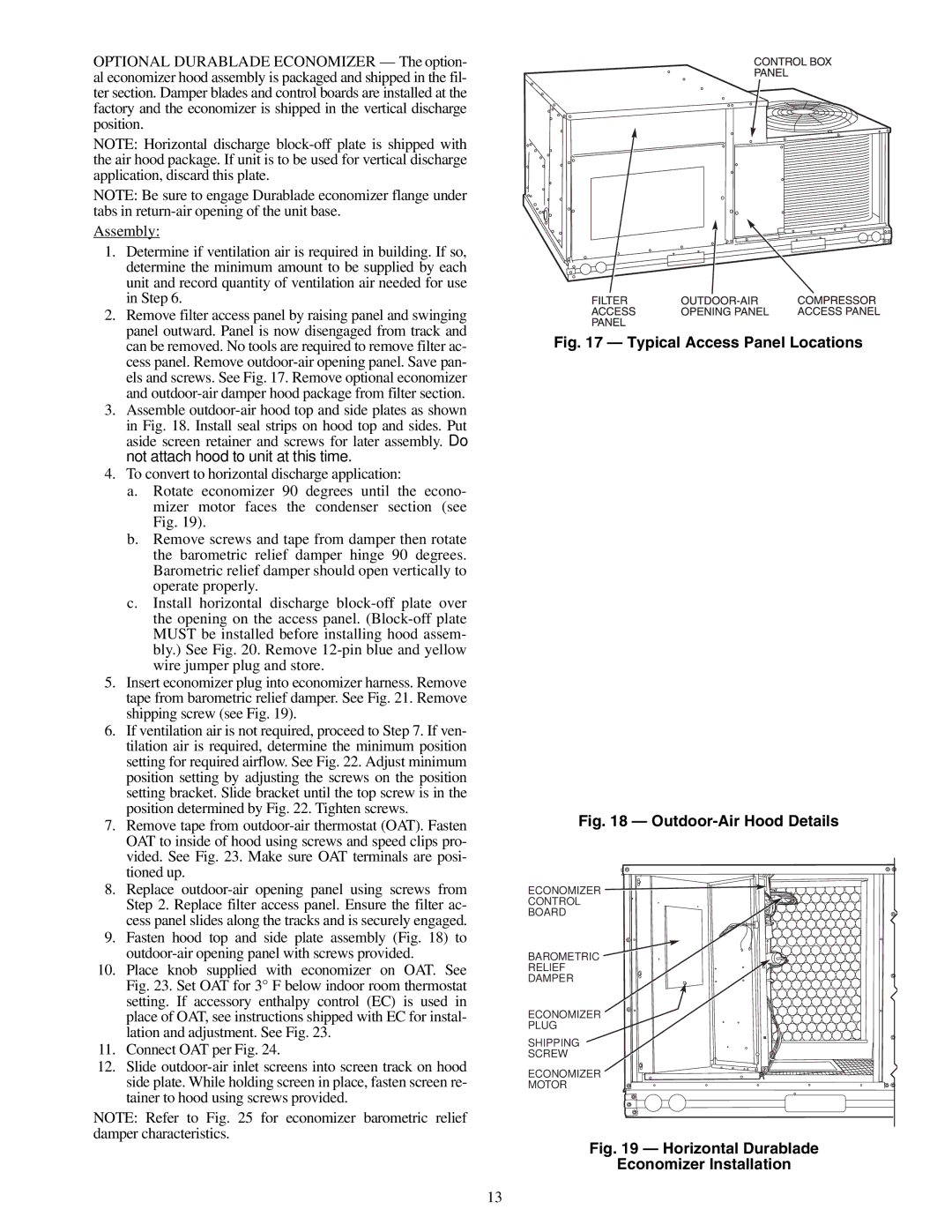

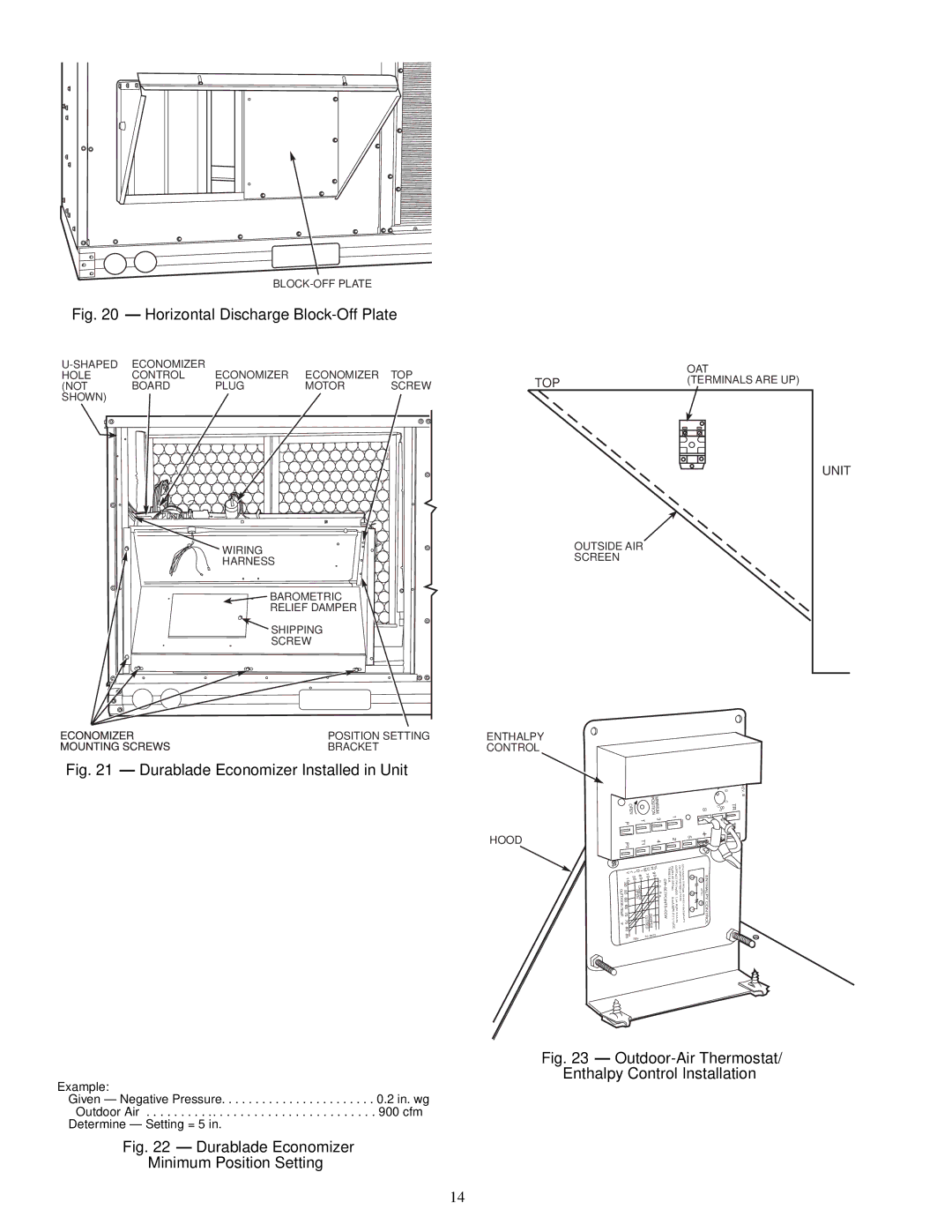

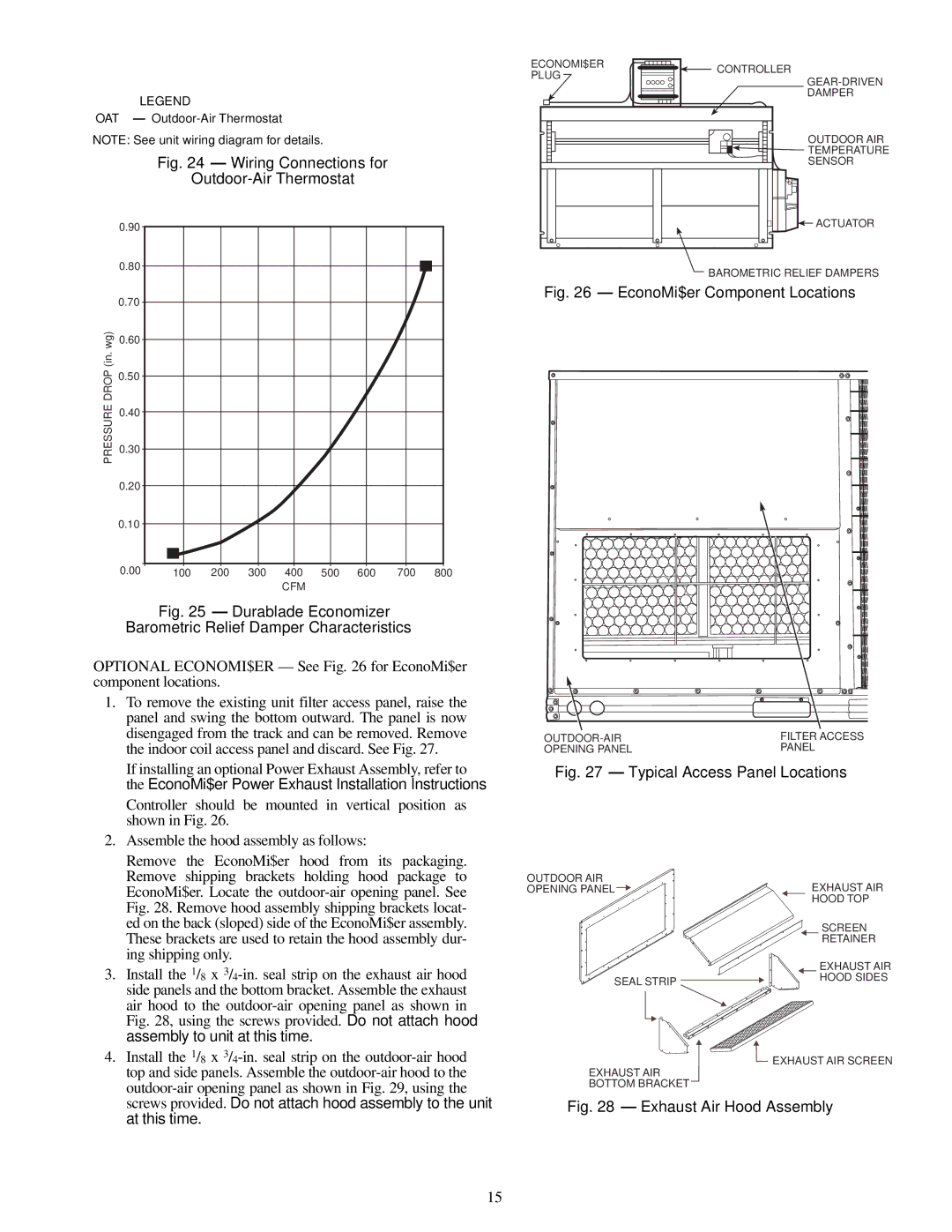

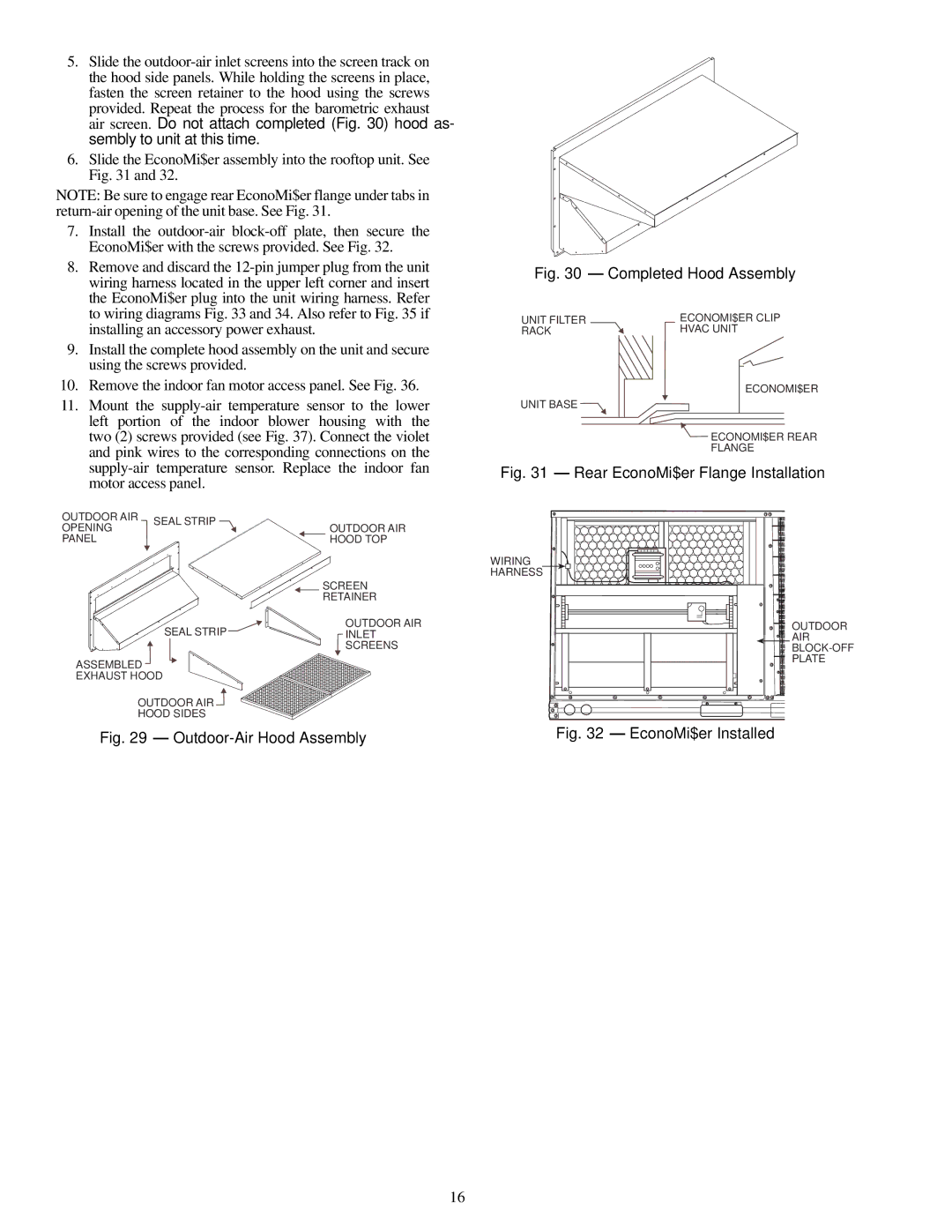

•OPTIONAL DURABLADE ECONOMIZER

•OPTIONAL ECONOMI$ER

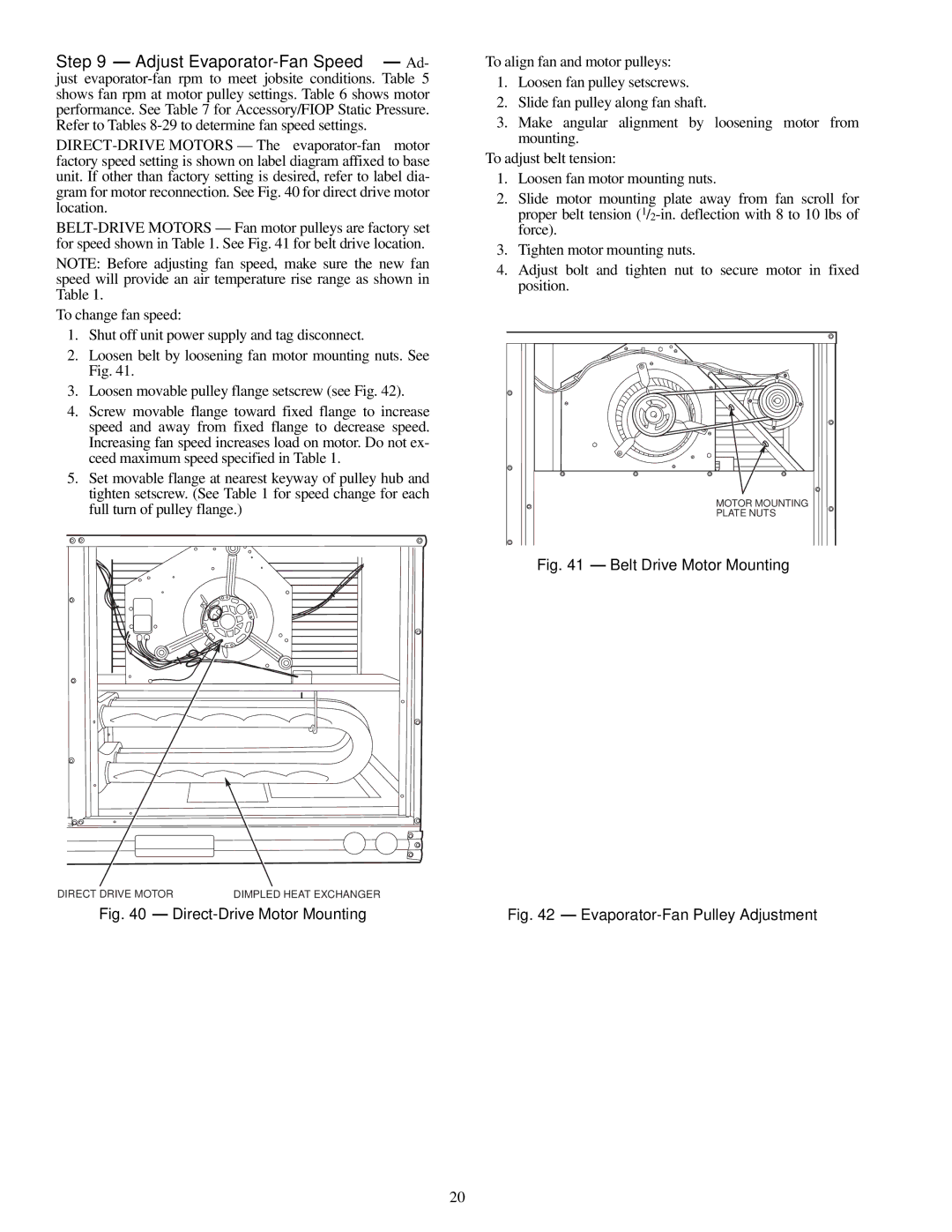

Step 9 — Adjust

•

•

SAFETY CONSIDERATIONS

Installation and servicing of

Untrained personnel can perform basic maintenance func- tions of cleaning coils and filters and replacing filters. All other operations should be performed by trained service personnel. When working on

Follow all safety codes. Wear safety glasses and work gloves. Use quenching cloth for unbrazing operations. Have fire extinguishers available for all brazing operations.

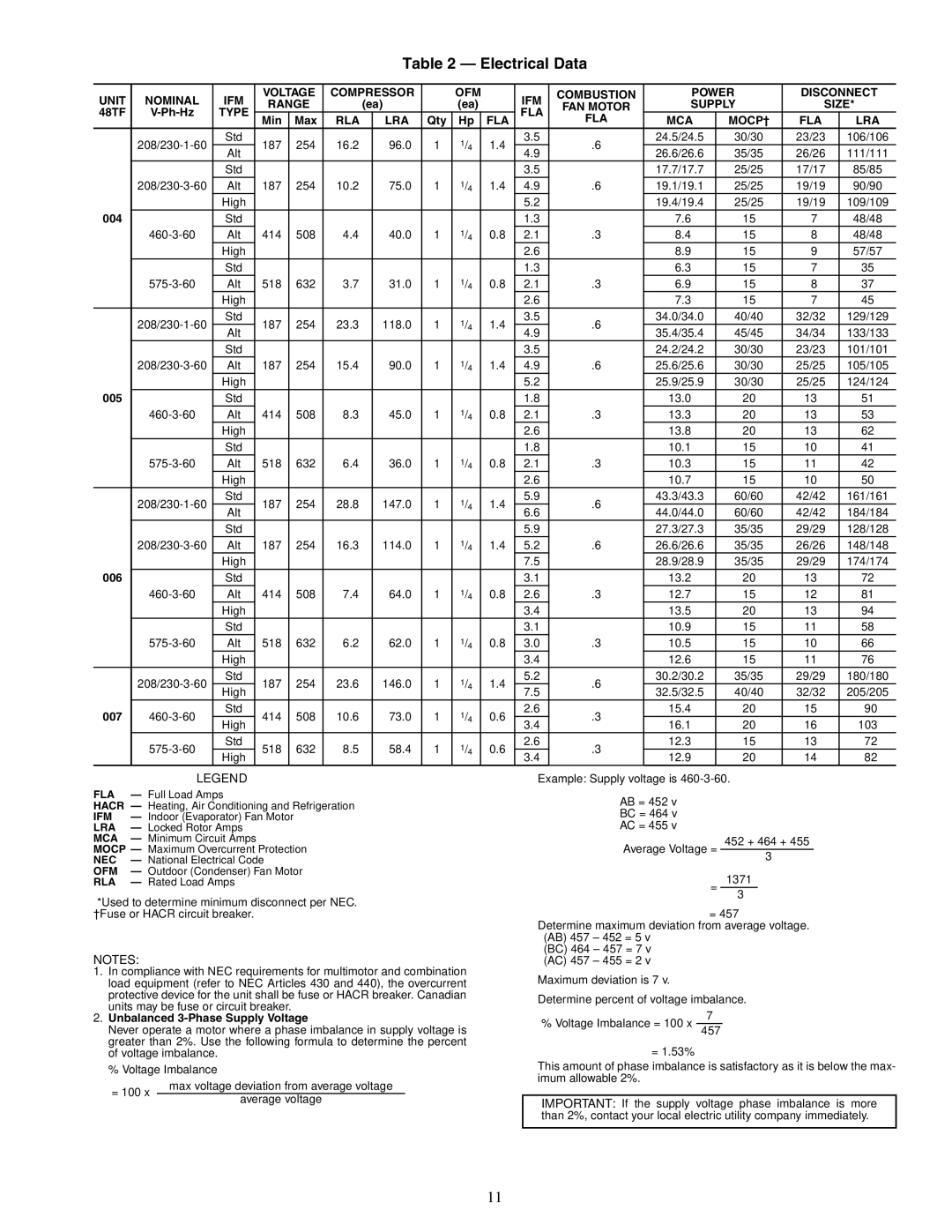

Ensure voltage listed on unit data plate agrees with electri- cal supply provided for the unit.

Disconnect gas piping from unit when leak testing at pressure greater than 1/2 psig. Pres- sures greater than 1/2 psig will cause gas valve damage resulting in hazardous condition. If gas valve is subjected to pressure greater than 1/2 psig, it must be replaced before use. When pressure testing

Before performing service or maintenance operations on unit, turn off main power switch to unit and install lockout tag. Electrical shock could cause personal injury.

INSTALLATION

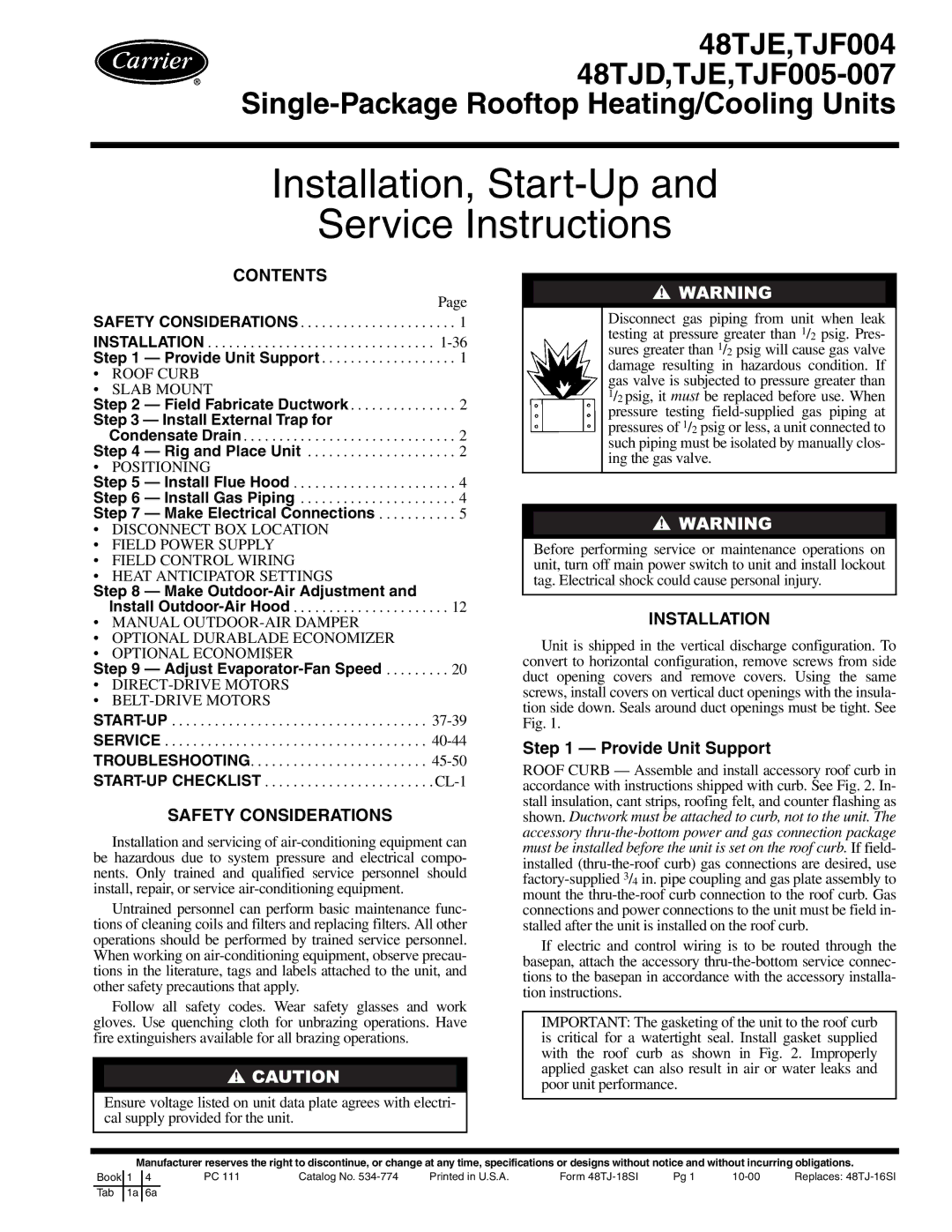

Unit is shipped in the vertical discharge configuration. To convert to horizontal configuration, remove screws from side duct opening covers and remove covers. Using the same screws, install covers on vertical duct openings with the insula- tion side down. Seals around duct openings must be tight. See Fig. 1.

Step 1 — Provide Unit Support

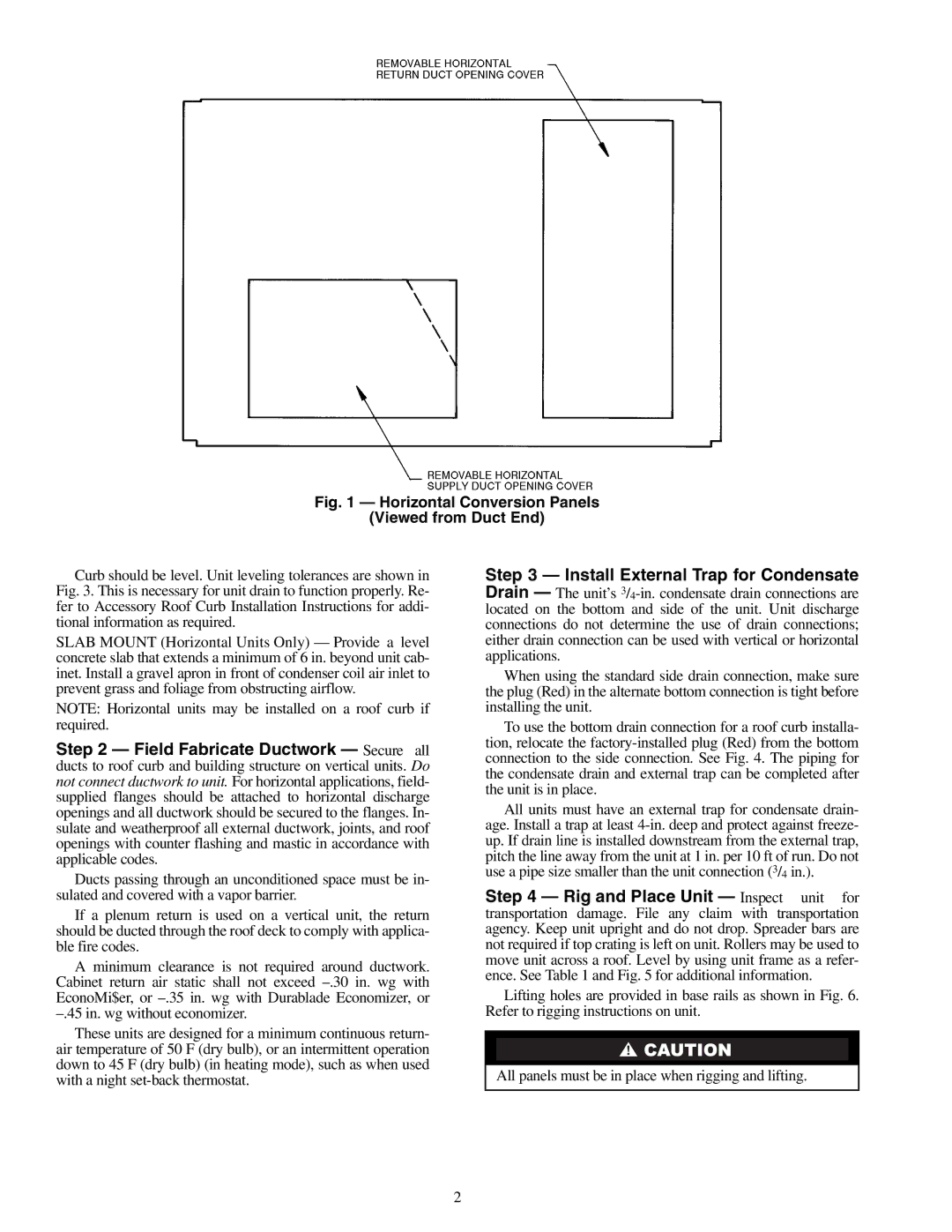

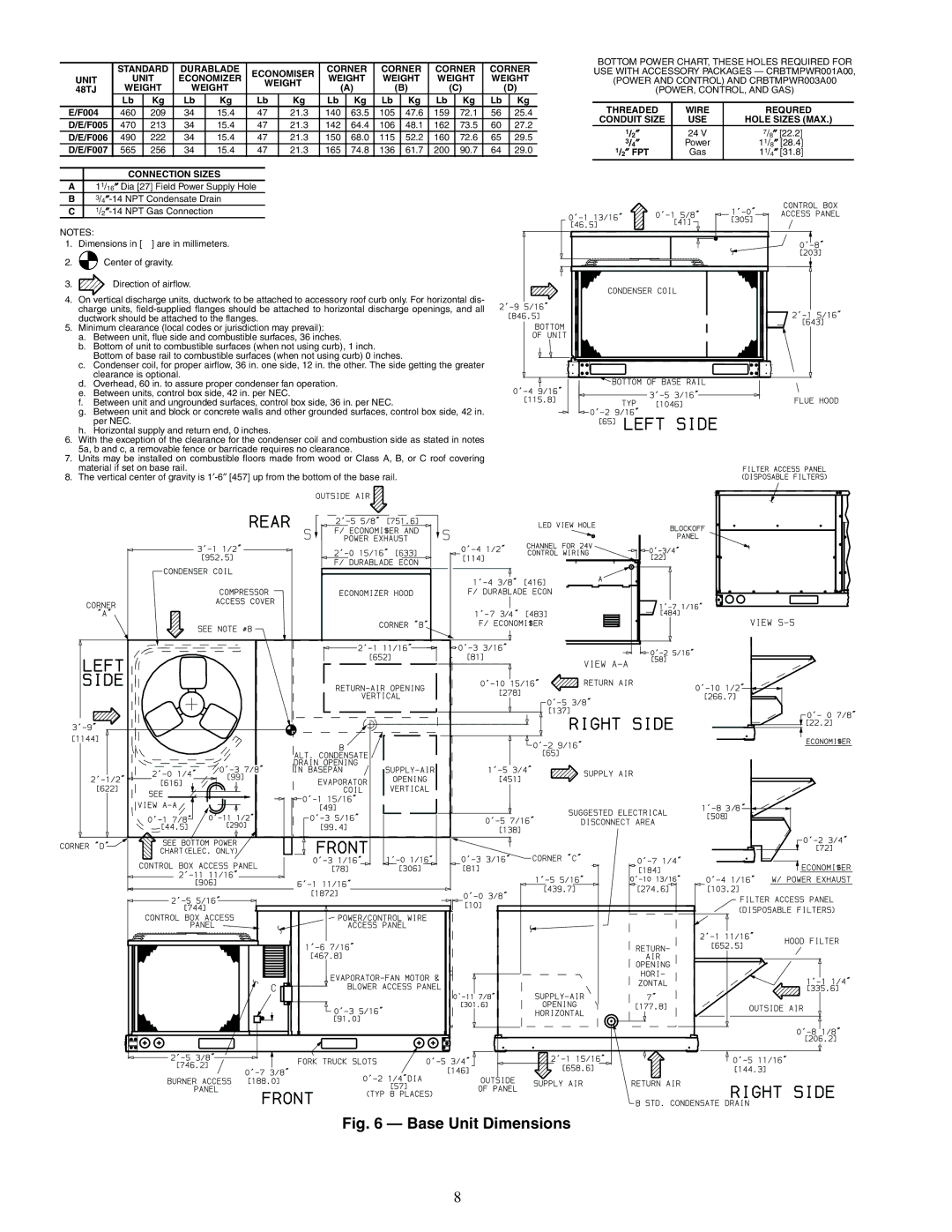

ROOF CURB — Assemble and install accessory roof curb in accordance with instructions shipped with curb. See Fig. 2. In- stall insulation, cant strips, roofing felt, and counter flashing as shown. Ductwork must be attached to curb, not to the unit. The accessory

If electric and control wiring is to be routed through the basepan, attach the accessory

IMPORTANT: The gasketing of the unit to the roof curb is critical for a watertight seal. Install gasket supplied with the roof curb as shown in Fig. 2. Improperly applied gasket can also result in air or water leaks and poor unit performance.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book | 1 | 4 | PC 111 | Catalog No. | Printed in U.S.A. | Form | Pg 1 | Replaces: | |

Tab | 1a | 6a |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|