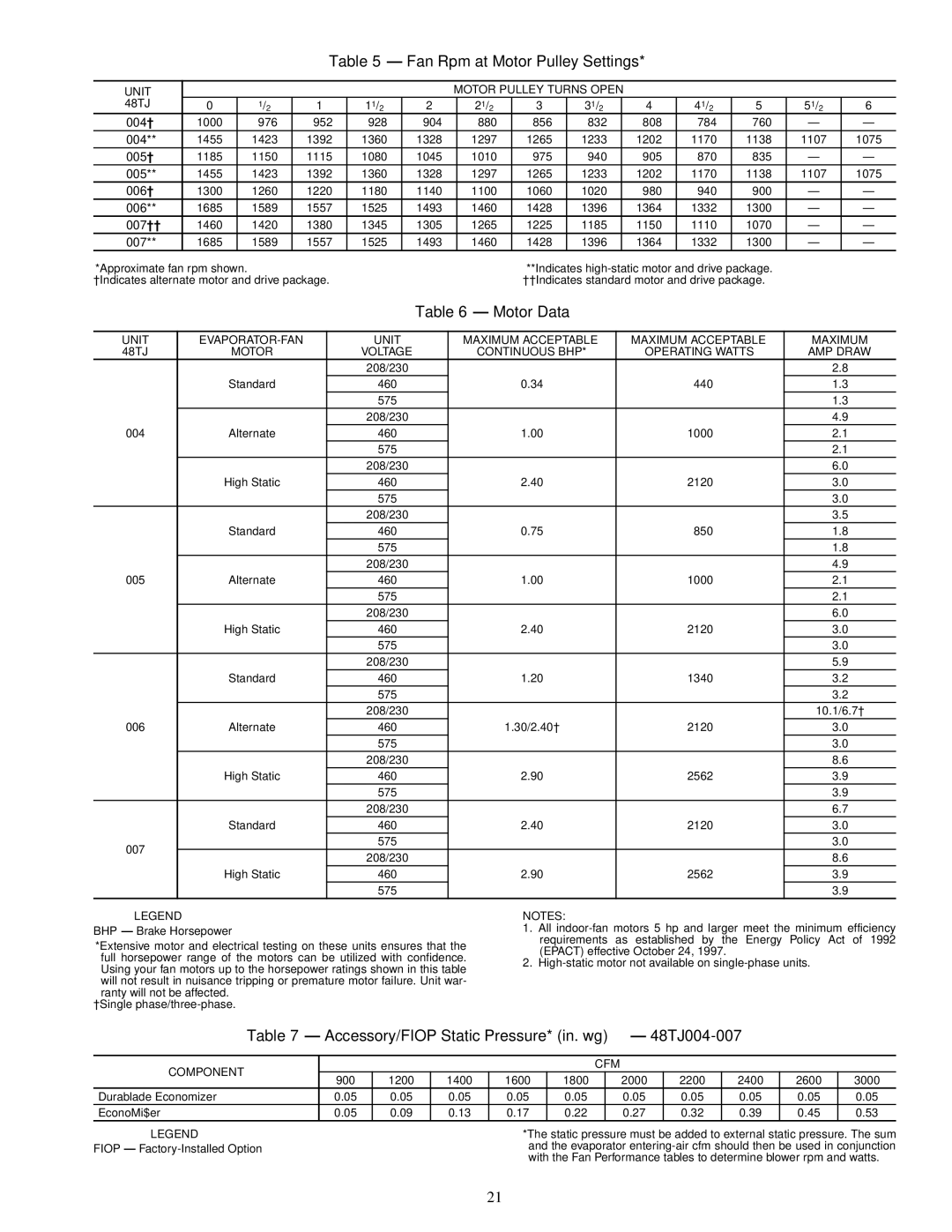

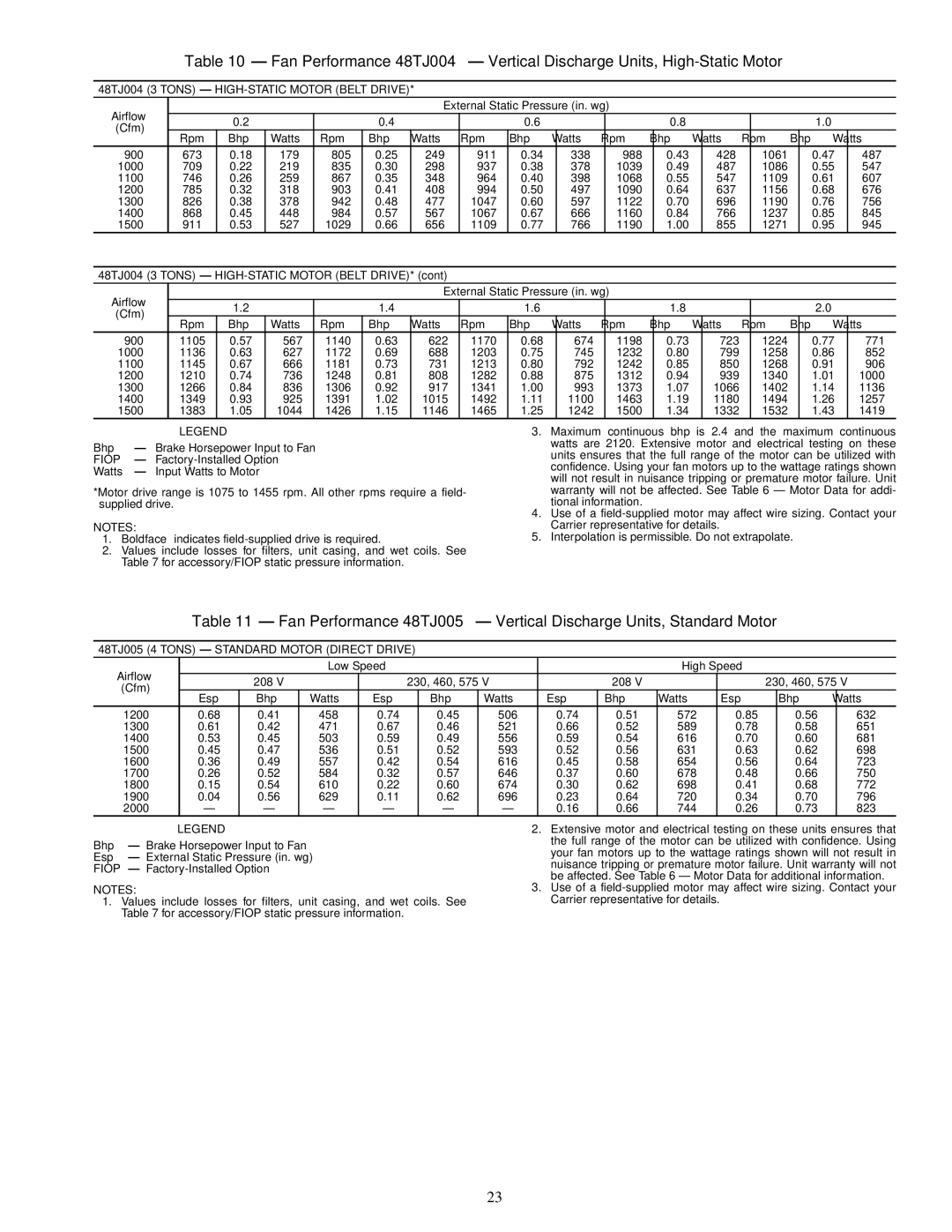

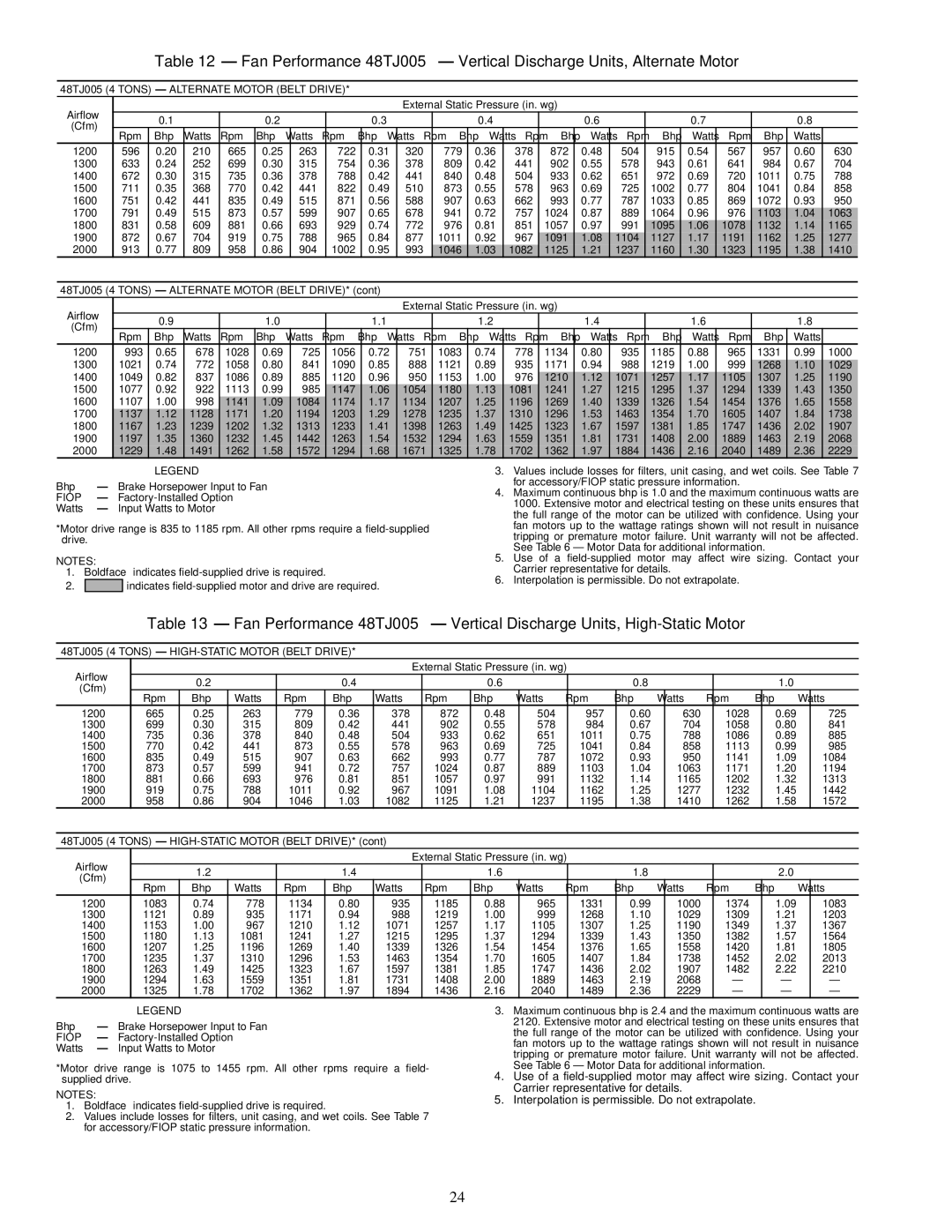

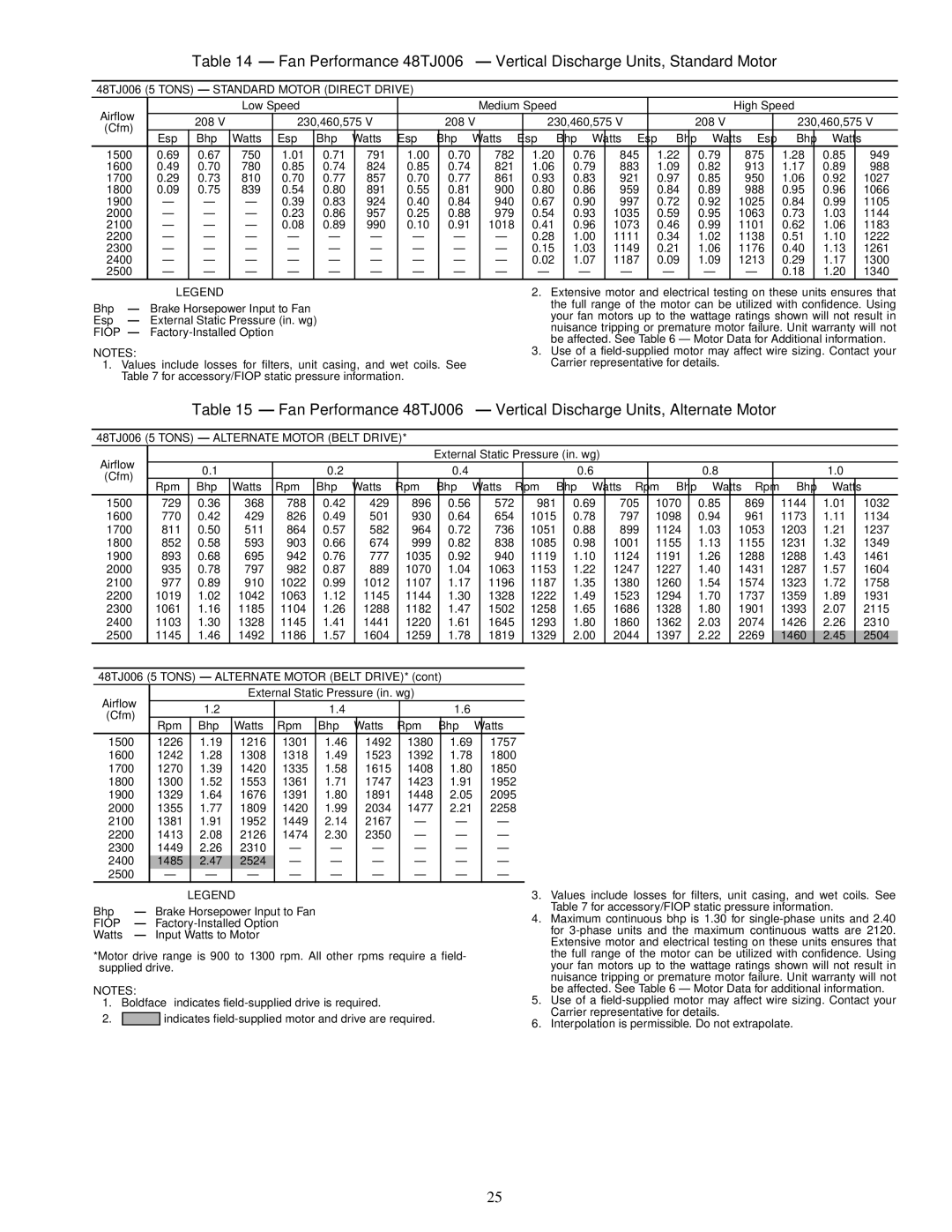

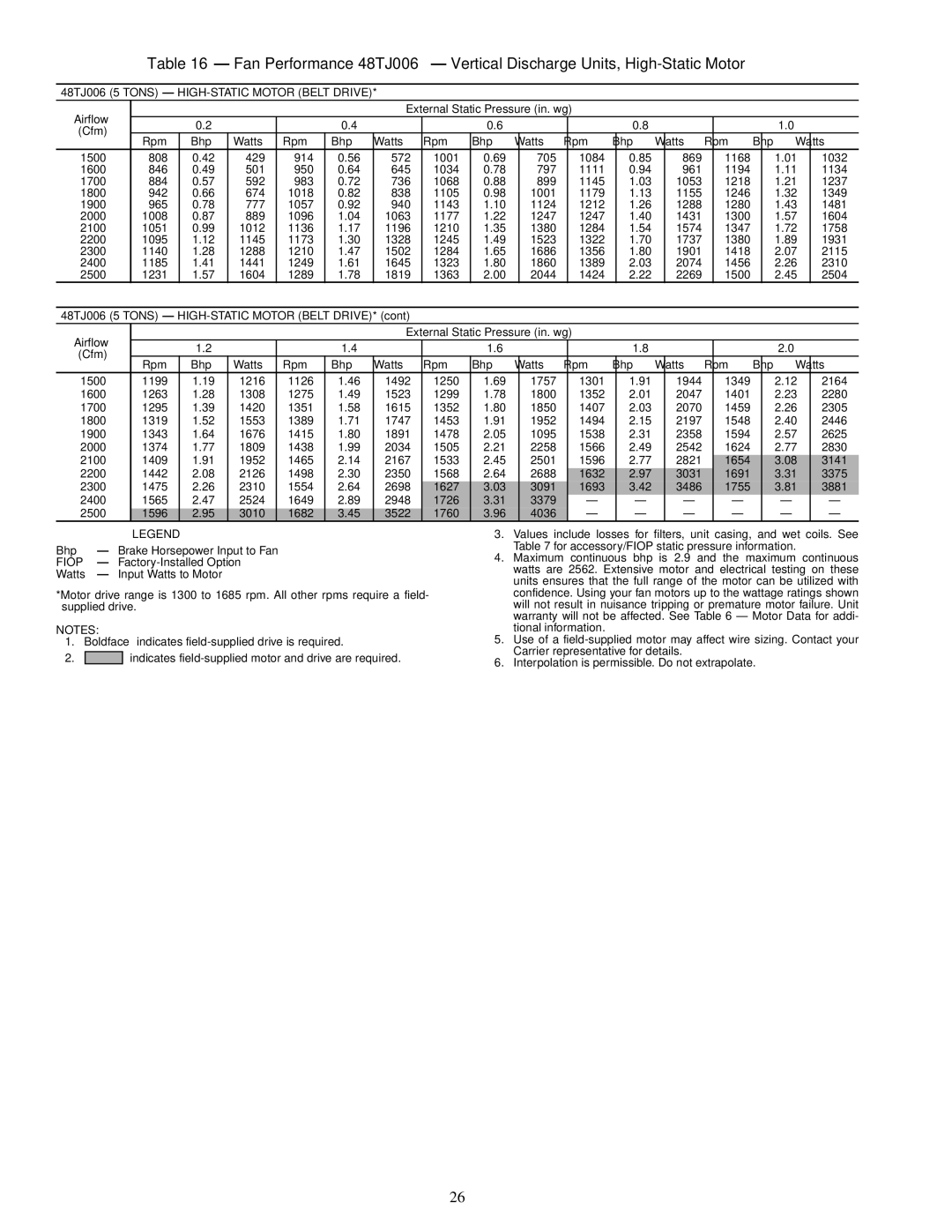

Table 16 — Fan Performance 48TJ006 — Vertical Discharge Units,

48TJ006 (5 TONS) — HIGH-STATIC MOTOR (BELT DRIVE)*

Airflow |

|

|

|

|

| External Static Pressure (in. wg) |

|

|

|

|

| ||||

| 0.2 |

|

| 0.4 |

|

| 0.6 |

|

| 0.8 |

|

| 1.0 |

| |

(Cfm) |

|

|

|

|

|

|

|

|

|

| |||||

| Rpm | Bhp | Watts | Rpm | Bhp | Watts | Rpm | Bhp | Watts | Rpm | Bhp | Watts | Rpm | Bhp | Watts |

1500 | 808 | 0.42 | 429 | 914 | 0.56 | 572 | 1001 | 0.69 | 705 | 1084 | 0.85 | 869 | 1168 | 1.01 | 1032 |

1600 | 846 | 0.49 | 501 | 950 | 0.64 | 645 | 1034 | 0.78 | 797 | 1111 | 0.94 | 961 | 1194 | 1.11 | 1134 |

1700 | 884 | 0.57 | 592 | 983 | 0.72 | 736 | 1068 | 0.88 | 899 | 1145 | 1.03 | 1053 | 1218 | 1.21 | 1237 |

1800 | 942 | 0.66 | 674 | 1018 | 0.82 | 838 | 1105 | 0.98 | 1001 | 1179 | 1.13 | 1155 | 1246 | 1.32 | 1349 |

1900 | 965 | 0.78 | 777 | 1057 | 0.92 | 940 | 1143 | 1.10 | 1124 | 1212 | 1.26 | 1288 | 1280 | 1.43 | 1481 |

2000 | 1008 | 0.87 | 889 | 1096 | 1.04 | 1063 | 1177 | 1.22 | 1247 | 1247 | 1.40 | 1431 | 1300 | 1.57 | 1604 |

2100 | 1051 | 0.99 | 1012 | 1136 | 1.17 | 1196 | 1210 | 1.35 | 1380 | 1284 | 1.54 | 1574 | 1347 | 1.72 | 1758 |

2200 | 1095 | 1.12 | 1145 | 1173 | 1.30 | 1328 | 1245 | 1.49 | 1523 | 1322 | 1.70 | 1737 | 1380 | 1.89 | 1931 |

2300 | 1140 | 1.28 | 1288 | 1210 | 1.47 | 1502 | 1284 | 1.65 | 1686 | 1356 | 1.80 | 1901 | 1418 | 2.07 | 2115 |

2400 | 1185 | 1.41 | 1441 | 1249 | 1.61 | 1645 | 1323 | 1.80 | 1860 | 1389 | 2.03 | 2074 | 1456 | 2.26 | 2310 |

2500 | 1231 | 1.57 | 1604 | 1289 | 1.78 | 1819 | 1363 | 2.00 | 2044 | 1424 | 2.22 | 2269 | 1500 | 2.45 | 2504 |

|

|

|

|

|

|

|

|

|

| ||||||

48TJ006 (5 TONS) — |

|

|

|

|

|

|

|

|

| ||||||

Airflow |

|

|

|

|

| External Static Pressure (in. wg) |

|

|

|

|

| ||||

| 1.2 |

|

| 1.4 |

|

| 1.6 |

|

| 1.8 |

|

| 2.0 |

| |

(Cfm) |

|

|

|

|

|

|

|

|

|

| |||||

| Rpm | Bhp | Watts | Rpm | Bhp | Watts | Rpm | Bhp | Watts | Rpm | Bhp | Watts | Rpm | Bhp | Watts |

1500 | 1199 | 1.19 | 1216 | 1126 | 1.46 | 1492 | 1250 | 1.69 | 1757 | 1301 | 1.91 | 1944 | 1349 | 2.12 | 2164 |

1600 | 1263 | 1.28 | 1308 | 1275 | 1.49 | 1523 | 1299 | 1.78 | 1800 | 1352 | 2.01 | 2047 | 1401 | 2.23 | 2280 |

1700 | 1295 | 1.39 | 1420 | 1351 | 1.58 | 1615 | 1352 | 1.80 | 1850 | 1407 | 2.03 | 2070 | 1459 | 2.26 | 2305 |

1800 | 1319 | 1.52 | 1553 | 1389 | 1.71 | 1747 | 1453 | 1.91 | 1952 | 1494 | 2.15 | 2197 | 1548 | 2.40 | 2446 |

1900 | 1343 | 1.64 | 1676 | 1415 | 1.80 | 1891 | 1478 | 2.05 | 1095 | 1538 | 2.31 | 2358 | 1594 | 2.57 | 2625 |

2000 | 1374 | 1.77 | 1809 | 1438 | 1.99 | 2034 | 1505 | 2.21 | 2258 | 1566 | 2.49 | 2542 | 1624 | 2.77 | 2830 |

2100 | 1409 | 1.91 | 1952 | 1465 | 2.14 | 2167 | 1533 | 2.45 | 2501 | 1596 | 2.77 | 2821 | 1654 | 3.08 | 3141 |

2200 | 1442 | 2.08 | 2126 | 1498 | 2.30 | 2350 | 1568 | 2.64 | 2688 | 1632 | 2.97 | 3031 | 1691 | 3.31 | 3375 |

2300 | 1475 | 2.26 | 2310 | 1554 | 2.64 | 2698 |

|

|

| 1693 | 3.42 | 3486 | 1755 | 3.81 | 3881 |

1627 | 3.03 | 3091 | |||||||||||||

2400 | 1565 | 2.47 | 2524 | 1649 | 2.89 | 2948 | 1726 | 3.31 | 3379 | — | — | — | — | — | — |

2500 |

|

|

|

|

|

| 1760 | 3.96 | 4036 | — | — | — | — | — | — |

1596 | 2.95 | 3010 | 1682 | 3.45 | 3522 | ||||||||||

LEGEND

Bhp — Brake Horsepower Input to Fan

FIOP —

Watts — Input Watts to Motor

*Motor drive range is 1300 to 1685 rpm. All other rpms require a field- supplied drive.

NOTES:

1.Boldface indicates

2.![]()

![]() indicates

indicates

3.Values include losses for filters, unit casing, and wet coils. See Table 7 for accessory/FIOP static pressure information.

4.Maximum continuous bhp is 2.9 and the maximum continuous watts are 2562. Extensive motor and electrical testing on these units ensures that the full range of the motor can be utilized with confidence. Using your fan motors up to the wattage ratings shown will not result in nuisance tripping or premature motor failure. Unit warranty will not be affected. See Table 6 — Motor Data for addi- tional information.

5.Use of a

6.Interpolation is permissible. Do not extrapolate.

26