403570-01 specifications

The Dukane 403570-01 is a sophisticated ultrasonic welding machine renowned for its versatility and efficiency in various industrial applications. Designed with advanced technology, this model is favored in sectors such as automotive, medical, textiles, and consumer goods for its ability to provide consistent and reliable weld results.One of the main features of the Dukane 403570-01 is its state-of-the-art ultrasonic transducer, which converts electrical energy into mechanical vibrations. This high-frequency sound wave technology allows for the joining of materials without the need for additional adhesives or fasteners, making it an environmentally friendly and cost-effective solution for manufacturers. The transducer operates at a frequency of 20 kHz, optimal for producing strong and durable welds.

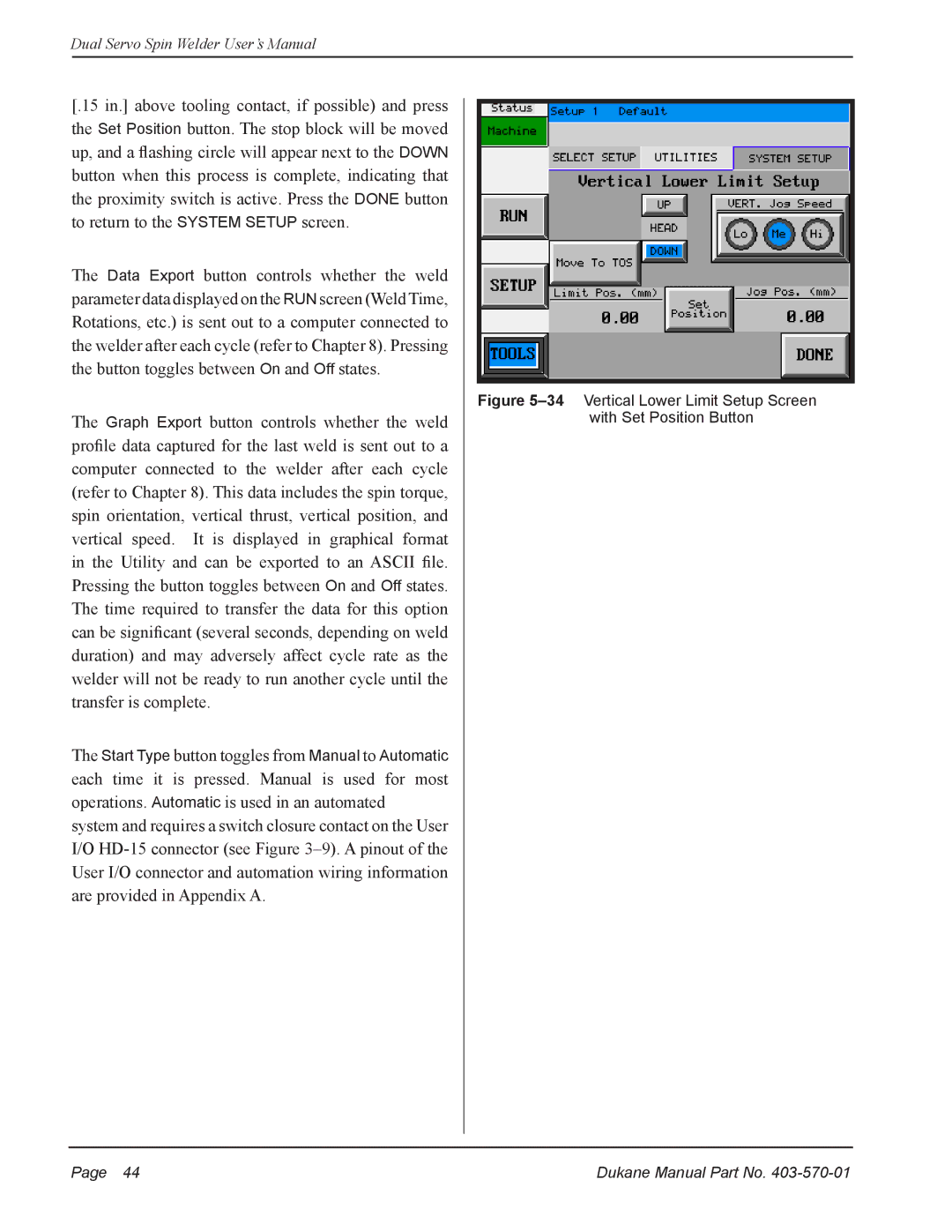

In addition to its transducer, the 403570-01 is equipped with an advanced generator that provides precise control over the welding process. This generator adjusts the energy output based on the materials being welded and the specific application, ensuring optimal settings for each job. The machine also features a user-friendly control panel that allows operators to easily program and monitor welding parameters such as time, power, and pressure.

The 403570-01 is designed for ease of use and maintenance. Its modular design simplifies servicing and allows for quick replacement of components, ensuring minimum downtime. Additionally, the machine’s lightweight construction enhances portability, making it suitable for both dedicated production lines and on-the-spot repairs.

Another significant characteristic of the Dukane 403570-01 is its versatility in handling various materials, including plastics, metals, and composites. This flexibility opens up a wide array of welding applications, from assembling intricate medical devices to automotive components. Furthermore, it features integrated safety measures that protect both the operator and the machine, reducing the risk of accidents during operation.

In summary, the Dukane 403570-01 stands out due to its advanced ultrasonic technology, user-friendly controls, and versatility in handling various materials. With its robust design and efficient welding capabilities, it is an invaluable asset for manufacturers looking to enhance their production processes and maintain high-quality standards.